Introduction to 120 RPM

The term 120 RPM (Revolutions Per Minute) is a crucial metric often used to define the speed at which various mechanical devices operate. Understanding this measurement is essential for manufacturers, engineers, and end-users alike, as it directly impacts the efficiency, output, and overall functionality of machines. In this guide, we will delve into the various aspects of 120 RPM, examining its significance in different industries and applications.

Types of Equipment Operating at 120 RPM

Many devices utilize a rotational speed of 120 RPM across diverse fields. Here are some common types you may encounter:

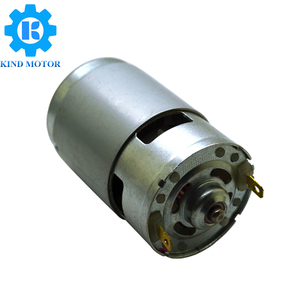

- Industrial Motors: Motors designed for production lines often feature 120 RPM settings to optimize output without compromising on energy efficiency.

- Blenders and Mixers: Commercial-grade kitchen equipment utilizes 120 RPM to ensure consistent mixing and blending for various food preparation processes.

- Fans and Blowers: HVAC systems commonly employ 120 RPM fans to maintain effective air circulation while managing energy consumption.

- Conveyor Belts: In manufacturing, conveyor systems moving at 120 RPM can handle materials effectively and maintain production flow.

Applications of 120 RPM in Various Industries

The 120 RPM speed setting is prevalent across multiple sectors, each benefiting from its unique advantages:

- Manufacturing: High-speed assembly lines often incorporate equipment operating at 120 RPM to increase throughput and meet heavy demand.

- Food Processing: Mixing and blending equipment running at this speed ensure uniformity in food production, crucial for taste and quality.

- Aerospace: Specific aircraft parts are tested at 120 RPM to simulate operational conditions and ensure safety standards.

- Automotive: CNC machines in automotive manufacturing employ 120 RPM for precision cutting and shaping processes.

Advantages of Using Equipment with 120 RPM

Investing in 120 RPM equipment can present several notable advantages that enhance operational efficiency and productivity:

- Energy Efficiency: Operating machinery at 120 RPM often requires less energy compared to higher-speed alternatives, leading to lower operational costs.

- Reduced Wear and Tear: Moderate speed reduces strain on components, extending the lifespan of machinery and minimizing maintenance costs.

- Improved Safety: Slower speeds can enhance user safety, significantly reducing the risks associated with fast-moving parts.

- Precision Control: Equipment functioning at 120 RPM allows for enhanced control in processes like mixing and cutting, resulting in better quality output.