(1585 products available)

15W power transformers can be categorized into different types. Each type serves distinct purposes based on the business's specific electrical needs.

Step-up transformers are essential in industries where high voltage is needed for specific operations. For instance, in manufacturing processes that require high voltage for machine operation, a step-up transformer increases the voltage from a lower level to the required higher level. This makes the transformer crucial in enhancing operational efficiency.

As the name suggests, these transformers can operate on two different voltage inputs. This feature is especially beneficial for businesses with equipment that requires varying voltage levels.

For example, a workshop with tools that operate at both 110V and 220V can use a dual-voltage transformer. It eliminates the need for separate transformers for each voltage requirement. It also saves space and reduces equipment costs.

One of the primary uses of isolation transformers in an industrial setup is to enhance safety. In industries where workers are exposed to electrical equipment, isolation transformers reduce the risk of electric shock. This is due to their ability to prevent transmission of electric shock when the output is connected to a grounded circuit.

Besides, isolation transformers are used to improve power quality. In industries where sensitive electronic equipment is affected by power fluctuations, isolation transformers provide a stable and clean power supply. It reduces noise and voltage fluctuations that may damage or disrupt the operation of sensitive equipment.

The ferroresonant transformer stabilizes output voltage through the use of a magnetic rigid element. This characteristic is essential for businesses in regions with fluctuating power supplies. By smoothing out voltage variations, these transformers protect sensitive machinery from damage.

Moreover, these transformers have a Vreg design. It ensures that even during periods of heavy load or system changes, the output voltage remains consistent. This feature is valuable in industries where maintaining a uniform voltage is critical for production quality.

The longevity of a transformer determines its reliability in production. Often, this is influenced by the quality of materials used in its construction.

Copper is the most common material for transformer windings due to its excellent conductivity. It is often used in a professional or industrial context. This is because copper provides efficient electrical conduction while ensuring durability. Its resistance to corrosion makes it suitable for diverse environments.

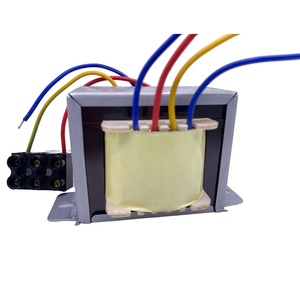

The core of a transformer is vital for its functioning. It ensures the efficient transfer of magnetic fields between windings. The cores are usually made from silicon steel laminated sheets. The laminations reduce energy losses caused by eddy currents, thus improving the transformer's efficiency.

Steel cores are designed to endure heavy usage while maintaining optimal performance. This makes them suitable for industries with constant electrical demands.

The insulation material used in a 15-watt transformer greatly impacts its durability. In most cases, resin-insulated wire is used to wind the coils. This wire provides excellent protection against electrical breakdowns and operates in high-stress environments.

Moreover, resin insulation is highly resistant to moisture and chemical exposure. This makes it suitable for industries with humid or chemically active conditions. Its ability to maintain insulation integrity over time ensures the transformer's long-lasting reliability.

Aluminium is occasionally used for transformer windings. This is because it is more affordable than copper. While aluminium has a slightly lower conductivity, it still offers efficient performance in many applications. Additionally, aluminium windings are corrosion-resistant. This makes them ideal for industries in marine or chemically active environments.

15W transformers come in handy in many commercial and business settings. Here, the transformers ensure electrical efficiency for various equipment used in daily operations.

For construction outfits using tools from different countries, a 15-watt transformer is a necessity. With the transformer, they can seamlessly operate both 110V and 220V tools. This eliminates the need to source extra electrical outlets or complicated wiring systems.

By standardizing their power tools, these businesses ensure consistent performance. It, in turn, saves them time and avoids the frustrations of electrical incompatibility. The overall result is a more efficient and streamlined work process.

For businesses that rely on neon signs, a power transformer for led signs is essential. It ensures the signs run smoothly, maintaining the desired voltage and current. This keeps the signs bright and visually appealing.

Restaurants, retailers, and service stations often use these transformers to power their signage and decorative lighting. A consistent and reliable lighting display attracts more clients. It enhances brand visibility and reinforces their signature aesthetic. This makes a 15-watt transformer an integral part of their promotional strategy.

In high-tech environments like data centers or server farms, stable power is vital. A 15-watt transformer is used to manage varying voltage levels. It keeps critical equipment running without interruption.

As mentioned earlier, these transformers are especially useful for international businesses. They might have systems that require either 110V or 220V. By incorporating these transformers, companies prevent power surges and fluctuations.

Most commercial heating, ventilation, and air conditioning (HVAC) systems rely on transformers. They use them to regulate voltage and ensure smooth operation. These transformers, like the 15-watt one, help in the efficient functioning of these systems. This keeps indoor environments comfortable for clients and staff alike.

Consistent temperature control also positively impacts client experience and productivity. Likewise, reliable HVAC systems reduce maintenance costs.

Several factors come into play when selecting an ideal 15-watt transformer. They impact its performance and suitability.

The design of a 15-watt transformer influences its operational efficiency and reliability in electrical systems. For businesses, especially, it is essential to consider the transformer core design. The core material and configuration can impact the energy losses during electrical conversion. Thus affecting overall efficiency.

Moreover, transformers with designs that reduce these losses can lead to significant long-term savings. For businesses that operate at high loads, a well-designed core can enhance thermal dissipation. Thus, reducing the risk of overheating and ensuring longer uninterrupted service.

Selection is ease of installation. A transformer that integrates smoothly into existing electrical systems can minimize downtime during setup. This is particularly vital for businesses that can't afford extended power outages.

Furthermore, transformers with universal mounting options and clear installation guidelines simplify the process. It reduces the installation time and effort required. This allows teams to quickly resume operations.

Maintenance is another key factor that impacts total cost of ownership. While some transformers require regular oil checks and part replacements, others are maintenance-free. Opting for low-maintenance models can decrease long-term operational burdens. These are often vital for companies that prioritize efficiency and have limited maintenance staff.

The 15-watt transformer's performance will depend on the operating conditions of the installation environment. It, therefore, makes it necessary to select a model that is built to withstand the conditions typical to one's work area. These can be extreme temperatures, high humidity, or exposure to dust and debris.

Additionally, selecting a transformer with adequate protection, such as weatherproof enclosures, can ensure its longevity. This, in turn, reduces the need for replacements.

A1. A 15-watt transformer regulates voltage into a more usable range for electronic devices and equipment. It does this by converting high voltage to lower voltage or vice versa. This allows businesses to operate their devices more efficiently. In turn, preventing damage from voltage fluctuations and ensuring optimal performance.

A2. Yes, 15-watt transformers are energy-efficient. Their design minimizes energy losses through heat dissipation and magnetic leakage. This makes them a cost-effective solution for powering devices.

Also, energy efficiency impacts operational costs either directly or indirectly. Therefore, investing in energy-efficient transformers reduces electricity costs over time.

A3. Some of the common signs of a failing transformer include obvious overheating, unusual noises, constant power fluctuations, and burning smells. Catching these signs early can prevent extended system outages. It also helps in saving expensive repairs and replacements.

A4. A 15-watt transformer can be used outdoors. Just ensure it has adequate weatherproof housings, like water-resistance ratings and corrosion protection. It will withstand outdoor elements like moisture, dust, and extreme temperatures while maintaining optimal performance.