(429 products available)

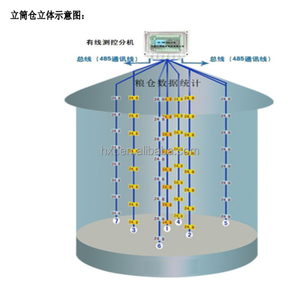

Thanks to technological advancement, 3D silos have become a popular storage option in various industries. Here are three common types of 3D silos:

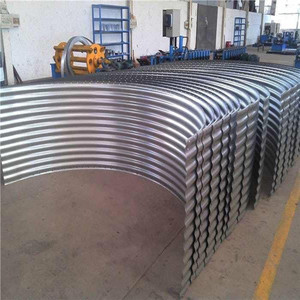

3D steel silo

The steel mill is usually made of galvanized or painted corrugated steel sheets. The sheets are then rolled into a cylinder to create the silo body. Engineering structures like columns and rings may be used to support steel silos and keep their shape. Large capacities are one of the benefits of steel silos. They can hold a large amount of material without taking up much horizontal space. Steel corrugated silos are also very sturdy and long-lasting. If maintained properly, they can last for many years and resist damage from the weather or heavy use. Furthermore, steel silos usually have good airtightness and can stop almost all kinds of gas from getting in or out. This feature helps control the materials inside and protects them from external contamination.

3D concrete silo

The concrete silo is built by pouring concrete into an ideal mold or using prefabricated concrete blocks. Steel silo is similar to concrete silos have great capacities and save land. Concrete silos are good choices for heavy industries and coastal areas because they allow materials like cement, grain, and coal to be stored conveniently and efficiently. Concrete silos are usually very secure, durable, and require low maintenance. They are a good option for storing materials that need to be protected from all kinds of weather. Concrete silos don't need any extra care after being built. Like steel silos, concrete silos are sturdy and long-lasting if used properly.

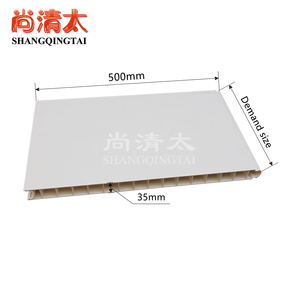

3D plastic silo

3D plastic silos are usually made of high-strength polyethylene (HDPE), which is a common plastic material. HDPE is strong and can bend a little without breaking. Rotomolding, blow molding, or injection molding are some ways to make plastic silos. This makes them have a smooth inside and outside. Plastic silos are lighter than steel or concrete silos. An employee can move and install them alone easily. Plastic silos also work well and save energy. They have lower friction resistance so that materials can flow through them quickly. Plastic silos are also weatherproof, waterproof, dustproof, and corrosion-resistant, which makes them suitable for storing different types of materials in various environments.

The following are the specifications for a 3D silo:

Grain Silo needs maintenance so that the food doesn’t get ruined or stale or spoiled. The following things must be done periodically:

Silo structures are commonplace in numerous industries including food production, building materials, oil refining, and logistics. They serve the purpose of storing bulk materials and providing seamless automation for storing, feeding, and discharging operations.

3D silos have application prospects in many industries.

Agriculture

3D silos can be used to store grains, feeds, seeds, and fertilizers, optimizing space utilization and ensuring the efficient storage of agricultural products.

Food industry

Food factories, bakeries, and breweries can use 3D silos to store flour, sugar, feed, malt, etc., meeting hygiene and automation requirements.

Construction industry

In construction, 3D silos can be used to store bulk cement, aggregates, and other materials, improving material management and productivity.

Chemical industry

3D silos can be applied in the chemical industry for storing plastics, rubbers, chemicals, etc., facilitating material distribution and inventory management.

Logistics industry

3D silos can be used in warehousing and logistics systems for storing and distributing bulk materials, optimizing storage space and improving operational efficiency.

Energy industry

3D silos can be employed in the energy sector to store coal, fly ash, biomass, and other fuels, aiding energy production and management.

Pharmacy

3D silos can be used for bulk drug storage, auxiliaries, packaging materials, etc., which can improve the efficiency of material management and meet the requirements of drug storage.

Business buyers should choose 3D Silo models based on their specific business needs. Here are some factors to consider:

Appplication

Select the material and function of the silo according to the purpose of use. For example, if storing grain as animal feed, choose a 3D grain silo made of a material that can be processed into animal feed.

Capacity

3D silos come in all kinds of sizes, so picking the right one depends on how much material a business needs to store. Make sure the silo's size fits with the business's operations and budget.

Design

Choose a silo that looks good and matches with the architectural style of the place where it will be used. Consider its visibility and impact on the surrounding environment.

Cost

Consider the upfront expense of buying the silo and any ongoing costs for taking care of and operating it. Make sure the silo selected is a cost-effective choice in the long run.

Supply chain integration

If the silo is part of a larger system used to store, handle and transport materials, make sure it can work well with other pieces of equipment and tools. Check that it will fit into the energy-efficient logistics process the business has.

Environmental impact

Consider the environmental impact of the silo, such as its energy use during operation and any emissions. Choose a silo that is environmentally sustainable and minimizes its ecological footprint.

Safety features

Check that the silo has safety elements like explosion prevention and proper ventilation. These features help keep workers safe from any possible hazards that could happen during use.

Q1: What types of materials are commonly stored in silos?

A1: Silos are commonly used to store agricultural products like grains, seeds, and fertilizers. However, they are also utilized in other industries to store cement, coal, calcium, kettles, glass, lsa, lime, marble, nitrogen, phosphorus, potassium, and other bulk chemicals.

Q2: What are the trends in silo design and technology?

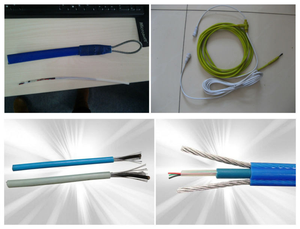

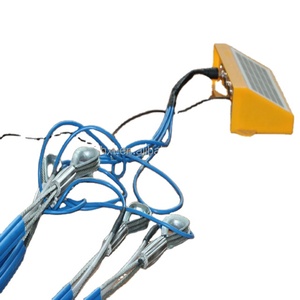

A2: The trend is toward intelligent silo systems integrated with a managerial database for real-time monitoring and inventory tracking. Besides, the use of sustainable materials and energy-efficient designs is also rising.

Q3: How long can materials be stored in a silo without degrading?

A3: It depends on the type of material and the conditions inside the silo. For example, grains can be stored for several months to a year in a properly maintained silo. Nonetheless, some materials may degrade or spoil after a few weeks or months.

Q4: What are the loading and unloading methods used for silo storage?

A4: The common methods include pneumatic conveying, gravity flow, drag chains, augers, air slides, and bucket elevators. Unloading methods vary depending on the silo's design and purpose, including pneumatic conveying, vibrating feeders, clinker grizzly and cement seals.

Q5: What are the safety measures for silo storage?

A5: Safety measures include regular maintenance and inspection, proper ventilation, explosion risk assessment, and training for employees. Besides, many modern silos have safety features like anti-flow regulation, safety valves, and overflow sensors.