(1011 products available)

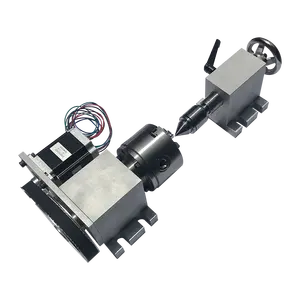

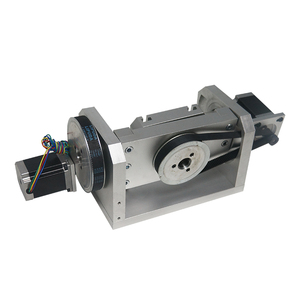

As an addition to a standard CNC machine, the 4th axis CNC rotary table allows the machining of a workpiece from multiple angles without repositioning it. These can be categorized into the following:

Maintaining a 4th axis CNC rotary table properly ensures its accuracy, longevity, and optimal performance. While maintenance may vary according to the type and model of the rotary tables, here are some general maintenance tips that apply to most 4th axis rotary tables:

Clean the Surface Regularly:

Debris, dust, and dirt can get accumulated on the workpiece and table surfaces. Regular cleaning ensures the removal of such contaminants, preventing the damage of the rotary table bearings and precision surfaces. Use a lint-free cloth and mild solvent to clean the surface of the 4th axis CNC rotary table. Make sure to avoid the use of harsh chemicals that can damage the surface coating of the table.

Lubrication:

Apply lubrication to the moving parts of the rotary axis table, such as the bearings and gears. It helps to minimize wear and tear while ensuring smooth operation. Always refer to the manufacturer's guidelines and use the recommended lubricants.

Regular Inspection:

Check the 4th axis CNC rotary table regularly for any signs of damage or excessive wear. Pay attention to the precision surfaces, bearings, and electronic components to identify and fix problems early and prevent further damage.

Optimize Workholding Fixtures:

Using improper workholding fixtures can increase the risk of rotary table damage as they might not securely hold the workpiece. Improperly held workpieces might slip or move during the machining process, exerting excess pressure and force on the rotary table. Choose the right and optimized workholding solution for each application. They help to ensure proper workpiece clamping and alignment on the rotary table, thereby reducing the risk of damage to the table.

4th axis CNC rotary tables are used in various industries for different applications, including the following:

Both the tafel rotative CNC 4th axis and the 4th axis laser rotary are important accessories for CNC machines. They all have their specific applications and benefits. When choosing one, it is important to consider the following crucial factors.

Workpiece Compatibility

The primary goal of a rotary axis is to work with a particular workpiece. As such, it is necessary to find out if the rotary table can adequately support the size and weight of the intended workpiece. Worry less about compatibility if the workpiece can be easily adjusted and mounted.

Precision and Accuracy

The main reason for using the rotary table is to increase the accuracy and precision of workpieces. Therefore, it is important to choose a rotary table with a high level of accuracy—typically, an axial table with a resolution of 0.01 or better.

Integration and Compatibility

A rotary table would typically work as an accessory to a CNC machine. As such, the table should integrate and be compatible with the existing CNC controller and software. This seamless integration will ensure that the rotary axis is adequately controlled alongside other CNC axes.

Transmission System

These rotary axes work via different transmission systems. Helical gears are among the most commonly used, as they provide smooth motion and low backlash. Other transmission systems may include belt drives and harmonic drives. Choose a transmission system that will provide adequate precision for the project at hand.

Build Quality and Sturdiness

Not all CNC tasks require the same level of robustness. A sturdy, well-built rotary axis will properly support delicate workpieces. However, it is also important to realize that a heavy-duty rotary axis will likely provide long-term service.

Q1: What are the two main types of CNC rotary tables?

A1: The two main types of CNC rotary tables are indexers and continuous rotation tables. Indexers typically have a limited range of motion (for example, 0-360) and rotate in increments of 90, 180, or any other preset value. They pause at each designated point. On the other hand, continuous rotary tables offer uninterrupted 360-degree rotation, allowing for constant turning and continuous movement in both clockwise and counterclockwise directions.

Q2: What Are the Benefits of 4th Axis CNC Machining?

A2: Enhanced Automation, Simplified Assembly, Improved Accuracy and Precision, Higher Production Rate, Better Utilization, Reduced Tooling Cost.

Q3: What is the programming like for CNC 4th axis rotary tables?

A3: CNC 4th-axis rotary tables are typically programmed using G-code, the standard programming language for CNC machines. Depending on the type of table attached to the CNC machine, different commands may be used to program it.

Q4: Can all CNC machines use rotary tables?

A4: No, unfortunately, not all CNC machines can use rotary tables. Rotary tables are usually compatible with CNC milling machines and routers. However, compatibility can vary, so it's essential to check the specifications and requirements of both the rotary table and the CNC machine to ensure they can be used together. Additionally, rotary tables are primarily designed for CNC milled work. So, if the CNC machine in question is not a milling machine, it may not be able to use a rotary table. For example, rotary tables aren't typically suitable for a CNC laser machine.