(5213 products available)

4x8 flakeboard, also known as oriented strand board (OSB), is an engineered wood product commonly used in construction and woodworking projects. It is made from large wood strands or flakes that are oriented in specific directions and bonded together with adhesives under heat and pressure. The result is a panel that is strong, stable, and versatile. The board comes in different grades, which determine its suitability for various applications. Here are some of the grades:

Structural OSB:

Structural OSB/OR (OSB for oriented reinforced): This grade is specifically designed for use in load-bearing applications. It is commonly used as roof decks, subfloors, and wall sheathing. The flakeboard is manufactured to meet specific performance requirements and withstand structural loads. They are identified by a stamped panel that shows the grade, orientation, and application.

Structural OSB/2: This grade is suitable for use in load-bearing applications that are exposed to humidity. For instance, it can be used as wall sheathing in dry locations. The board is identified by a stamp that shows OSB/2 and the panel thickness.

Structural OSB/3: This grade is suitable for use in load-bearing applications that are exposed to humid conditions. For example, it can be used as wall sheathing in wet locations like bathrooms. The boards are identified by a stamp showing OSB/3 and the panel thickness.

Non-Structural OSB:

Non-Structural OSB/4: This grade is not recommended for use in load-bearing applications. It is primarily used for applications where no structural support is required. For instance, it can be used for interior partitions, decorative wall coverings, and furniture components.

Non-Structural OSB/4 is not subjected to stringent testing and is identified by a stamp showing OSB/4 and the panel thickness. It is also known as OSB for applications other than walls, roofs, and subfloors.

Specialized OSB:

There are several types of flakeboard that fall under specialized OSB. For instance, OSB/Fire Rated: This type of flakeboard is treated with fire-resistant chemicals during manufacturing. This helps to meet specific building code requirements. It is commonly used in commercial construction projects where fire safety is a priority.

Another type is OSB/Tongue and Groove: This type of flakeboard is designed with interlocking edges (tongue and groove) on the sides. This allows for a tight, seamless joint when the panels are installed. It is commonly used in roofing and flooring applications.

Understanding the features and functions of flakeboards helps to use them appropriately. Here are the fundamental characteristics and functions of 4x8 flakeboards.

Substrate for Laminate

The 4x8 flakeboard acts as a base when laminating floors. They carry the laminate material efficiently, making the laminate floors stable and long-lasting.

Support for Fixtures

The 4x8 flakeboard provides a solid foundation for hardware and fixtures in furniture construction. It can bear the weight of installed fixtures without bowing or breaking, providing longevity to the furniture.

Structural Strength

The 4x8 flakeboard offers dimensional stability and strength. It has a uniform thickness, which helps maintain a flat surface in applications. This ensures the laminate surfaces are even and stable, enhancing their longevity.

Cost-Effectiveness

The 4x8 flakeboard is budget-friendly compared to other boards. This makes it a popular choice among manufacturers looking to construct cost-efficient furniture without compromising quality.

Versatility

The 4x8 flakeboard is versatile. It is used in many applications, from furniture construction to laminate flooring and storage units. This versatility makes it a popular choice among manufacturers since they can use it to construct different items.

Environmentally Friendly

The 4x8 flakeboard is made from recycled materials. This makes it a sustainable choice for environmentally conscious manufacturers. Using flakeboards reduces the number of waste materials in the environment.

Ease of Workability

The 4x8 flakeboard can be easily cut and shaped into different designs and sizes. This makes it easy for manufacturers to construct items using simple tools.

Resistance to Warping and Shrinking

The 4x8 flakeboard is treated to resist moisture. This prevents it from shrinking and warping, which helps maintain the stability and integrity of the furniture or structure.

Flakeboards are versatile, engineered wood products that consist of a mat of smaller wood particles bonded together with resin and formed under heat and pressure. These boards are commonly used in the construction of buildings and other projects for both residential and commercial purposes. Some common application scenarios include:

Cabinets and Furniture

Cabinets and furniture provide a huge market for 4x8 flakeboards. Whether in a house, an office, or any other establishment, furniture is a common sight. The convenience of working with large-sized boards that can be cut and fitted as needed is a significant selling point for business owners in the furniture and cabinetry industry. With the right edges and finishes applied, 4x8 flakeboards can serve as a more affordable alternative to solid wood or higher-grade plywood in cabinet construction and furniture pieces such as desks, bookcases, and storage units.

Backing for Upholstered Furniture

Upholstered furniture is another common application for 4x8 flakeboards. Here, the boards are used as a structural base or backing. The advantages of using flakeboards in this application include cost reduction and weight reduction. The upholstered furniture industry represents a substantial market for 4x8 flakeboards, with demand driven by residential and commercial furniture production.

Wardrobes and Modular Storage Units

Wardrobes and modular storage units are often constructed using 4x8 flakeboards. The application of these boards in the construction of wardrobes is a common scenario since most modern designs use walk-in wardrobes that require the use of 4x8 boards. However, it is important to note that most traditional designs of wardrobes used in homes and storage spaces are constructed using solid wood.

Decorative Wall Panels

Decorative wall panels are another application scenario of flakeboards. These boards are used to manufacture decorative wall panels since they can be finished with veneers, laminates, or decorative prints that add texture and visual interest to walls. The advantage of using flakeboards in this application is that they provide a lightweight and cost-effective alternative to solid wood or high-grade panel products.

Choosing the right flake board involves considering various factors. Here are some of them:

Consider the grade

There are different grades of 4x8 flakeboards with various applications. Select the appropriate grade according to the intended use. For example, choose a high-grade load-bearing OSB board for structural support and a decorative grade for visual appeal.

Consider the thickness and load-bearing capacity

The 4x8 flakeboard comes in different thicknesses. Choose a thickness that suits the load requirements. Consider the load-bearing capacity if the board is used for shelving or subflooring.

Check the environmental certification

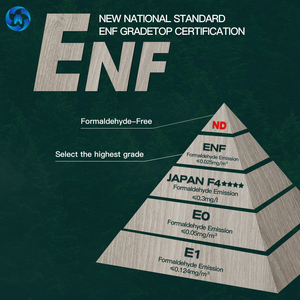

Those who prioritize environmental responsibility should select a flake board certified by recognized organizations. The certifications show that the manufacturer used sustainable practices in the production process and used waste materials.

Access the edge treatment

Some boards have T&G edges. These edges help in creating a stable and seamless joint. Consider the type of joint required when choosing the edge treatment.

Access the finishing options

The finishing options available on the 4x8 flakeboard include pressure-treated, pre-primed, and textured finishes. Pressure-treated boards have chemicals that prevent rot and insect damage. The pre-primed boards have a primer on the surface to facilitate easy painting. The textured boards have a unique surface pattern. Choose a board with the required finishing option.

Check the price

Flakeboards come with different price points. Consider the budget when choosing. However, don't compromise the quality for the price. Always choose a board with a competitive price and meets the quality standards.

Q1: Is it easy to work with 4x8 flakeboards?

A1: Absolutely. 4x8 boards are simple to handle and cut, making them an excellent choice for DIYers and small-scale projects.

Q2: What are the downsides of flakeboards?

A2: While flakeboards are a cost-effective option, they are not as durable as plywood. They may be more susceptible to moisture damage and should not be load-bearing in large areas.

Q3: Can flakeboards be painted or stained?

A3: Yes, it is possible to paint or stain flakeboards. However, it is advisable to use a primer on the boards first to achieve a better finish.

Q4: Are the adhesives used to make flakeboards harmful?

A4: Some adhesives used in making flakeboards contain urea-formaldehyde, which can be harmful. However, manufacturers are aware of this and have developed ways to minimize this. For instance, standard and high-density boards are made with no added formaldehyde. Moreover, the adhesives are usually cured and hardened during the manufacturing process. As a result, they don't pose any risk during use.

Q5: What is the lifespan of a flakeboard?

A5: The lifespan of a 4x8 flakeboard varies depending on factors such as exposure to moisture and how it is used. Generally, they last between 10-20 years. However, proper installation and maintenance are important to maximize their lifespan.