(674 products available)

9m electric poles come in diverse types suited for specific applications and requirements. When purchasing in bulk, business owners should consider the material, use, and design type, among other factors.

These poles are primarily designed to carry high voltage power lines over long distances. They are usually manufactured with tough materials like steel and concrete to ensure strength and durability. A 9m transmission pole is typically used in urban areas to provide clearance for underground utilities and support the tension of the power lines.

These are usually installed near populated areas to distribute lower-voltage power from substations to residences and businesses. A 9m distribution pole is ideal for carrying wiring, transformers, and other equipment. Wooden and fiberglass poles are commonly used in construction.

These are meant to support telephone, internet, and television cables. They are smaller and lighter compared to transmission and distribution poles. Nine-meter communication poles are suitable for running fiber optics or coaxial cable. They are frequently built using materials such as wood and fiberglass.

These support streetlights and offer a mounting point for signage and traffic lights. Street lighting poles are aesthetically pleasing and come with several designs to improve the area’s outlook. A 9m street light pole makes an ideal height for lighting up parks, roads, and other open spaces.

This pole is used for carrying electrical wires in a horizontal configuration. It is mostly used in setting up distribution lines but can also be applied in transmission line construction. A 9m Hframe is appropriate for situations where more stability and support are required when running multiple conductors.

Trellis poles are used for the type of construction that involves laying transmission lines. They are ideal for supporting conductors and provide the necessary insulation between high voltage wires and the ground. A 9m trellis pole is perfect for providing stability for medium to high voltage lines.

The 9m pole height is ideal for several applications, from streetlights to power transmission. It mainly comes in five types of materials: concrete, steel, wood, fiberglass, and metal composite. Each material serves different needs and has distinct pros and cons. Here’s a closer view at each of them:

Reinforced concrete electric poles are manufactured for durability and strength. They resist weather elements, have a long operational lifespan, and bear heavy loads. They are also reasonably priced. The poles are typically heavy to transport, so a lifting machine may be needed.

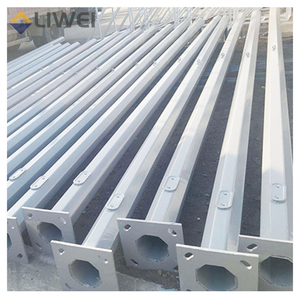

Steel poles are manufactured for strength, resilience, and flexibility. They are ideal for areas prone to high winds and storms. Their resistance to corrosion ensures long-term use. Steel poles are also more expensive than other varieties and are usually heavier, which can complicate the installation process.

These are the most popular poles used. Usually, they are pressure-treated the wood used to make the electric poles is cost-effective, lightweight, and easily installable. Although less durable, wooden poles provide a natural aesthetic. In addition, they may require more maintenance over time.

These are lightweight and easy to manage during the installation. Fiberglass poles resist corrosion and are ideal for coastal or chemically polluted environments. They also have great electrical insulation properties. However, they are more costly and not as strong as a steel or concrete pole.

These combine the positives of different materials. They offer the strength of steel and the lightweight nature of other materials. These poles are resistant to corrosion and come with a metal layer outside but are as light as wooden poles, making them easy to install. However, they are more expensive compared to regular wooden and even steel poles.

These electric poles are majorly used in distributing and transmitting electricity. They serve as support for power lines, enabling the transmission of high voltage across long distances. They also facilitate the distribution of lower voltage power to businesses and commercial facilities. These poles ensure reliable power supply and support infrastructure for energy needs.

9m electric poles also support communication cables for telephone, internet, and cable television. They create the infrastructure needed to help maintain connectivity in residential and commercial properties. By providing a medium for transmitting fiber optics and coaxial cables, these poles assist in delivering essential telecommunication services.

These electric poles are installed in urban settings for lighting streets, parks, and public spaces. They provide a mounting point for streetlights and improve safety and visibility at night. The brightness offered improves aesthetics and assures the safety of pedestrians and drivers. Beyond lighting, they also add to the overall design of the environment.

The electric poles are also applied in displaying signs, banners, and advertisements. Businesses can use these poles to hang banners or digital signage that promote their business. This provides an economical approach to advertising and improves the visibility of brands within the surroundings. They can be utilized to install promotional signs with minimal impact on the surroundings.

These are also used for mounting traffic signals, indicators, and sensors. They assist in controlling traffic flow and provide updates and information to drivers. By supporting modern traffic management systems, they help reduce congestion and improve road safety. These electric poles help integrate technology into traffic monitoring and management systems.

When purchasing a 9m electric pole in bulk, business owners need to consider various factors to get the best. Here are some of the factors to consider:

Transmission electric poles are suitable for heavy-duty tasks, while wooden ones are for light tasks. Communications poles are usually lighter and shorter, while street lighting poles are more decorative yet functional.

Select the right material based on strength, ease of installation, maintenance needs, and environmental factors. Concrete and steel are suitable in areas where high winds and storms are common. Wood, fiberglass, and metal composite are best in normal weather conditions.

Weight will affect the transportation and installation costs. Also, heavier poles will require a lifting machine during installation. Concrete and steel poles are usually heavy, whereas wooden, fiberglass, and metal composite poles are lighter.

Higher poles are preferred for higher load-bearing capacity. Does the pole need to support power lines, street lights, or telecommunication cables? Different poles are meant to support varying load requirements. For example, steel and concrete poles are suitable for heavier loads. In contrast, wood or fiberglass poles are suitable for lighter loads.

Budget is a determining factor in selecting the 9m electric pole. Each type of pole is manufactured at a different price. For instance, wooden poles are cost-effective, while fiberglass and metal composite are more expensive. Consider long-term benefits of reduced maintenance costs, especially if the pole is in a high-risk area.

Some electric poles require special skills and equipment for installation. Steel and concrete poles are more difficult to install and will require additional equipment or a professional team. But a concrete fence pole is easier to install if the buyer goes for lightweight options like composites, wood, and fiberglass.

Different electric poles have divergent maintenance requirements. Fiberglass and metal composite poles require little maintenance compared to wooden and concrete poles. Concrete poles may require inspections for cracks, while wooden ones need periodic treatment to avoid pests.

As installers and designers place solar systems in areas unsuitable for building concrete poles, they help hold the system together with the solar panels. This provides a space-efficient way to install solar systems and is a key component of mounting solar panels.

The height of an electric pole does not necessarily determine durability. 9m electric poles and 8m electric poles are equally durable, depending on the materials used to build them. But if the electric poles are built using more durable material, the 9m electric pole might be more durable since it offers more height stability.

Yes, electric poles can be shortened through various methods. The most popular method is sawing off a portion of the pole. This shortens the height without compromising on functionality. But the operation is risky and should only be performed by experienced individuals. Using a pole pruner is also effective for fiberglass and wooden poles.

Certain factors like material, weather element, and usage will determine how often to replace the pole. 9m wood electric poles normally last up to 25 years. Concrete poles last upwards of 50 years, while metal poles have a lifespan of 20 to 40 years. Fiberglass poles have a 30-year lifespan.

Several indicators will inform the owner that it’s time to replace the pole. Rotting and splinting for wooden poles is a great indicator. If it leans or bows, the pole needs urgent replacement. Serious visible cracks and spalling in concrete poles indicate that the pole has degraded. Ground electrolysis in metal poles requires immediate replacement.