(199592 products available)

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

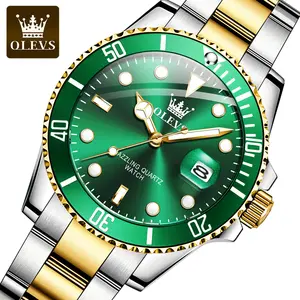

Stainless Steel Alloy Watches

Stainless-steel- alloy watches are renowned for their strength, durability, and resistance to corrosion. By integrating different types of steel, such as nickel and chromium, these watches offer a balance of rigidity and flexibility. This combination not only makes them suitable for everyday use, especially in harsh environments, but also ensures a sleek, modern appearance that never goes out of style. Aside from their durability, these watches require minimal maintenance, which adds to their appeal. Many stainless-steel- alloy watches are also water- resistant, making them perfect for swimming or other water- related activities.

Copper Alloy Watches

Watches with copper- based alloys provide a unique appeal due to their warm hues and antimicrobial properties. Often blended with materials like zinc or nickel to create bronze or brass, these alloys yield a combination of durability and aesthetic charm. While not as resistant to corrosion as stainless steel, copper alloy watches develop a distinctive patina over time, which many users find appealing. This gives each watch a personalized look while still offering a sturdy and reliable timekeeping solution. Additionally, the historical significance of copper in watchmaking adds an artistic touch to modern designs.

Titanium Alloy Watches

Titanium is consistently praised for being lightweight and exceptionally strong. When combined with other metals, like aluminum or nickel, it forms an alloy that is both highly durable and corrosion- resistant. titanium alloy watches are especially popular among professionals and outdoor enthusiasts, as the comfort of wearing these watches over long periods is guaranteed without sacrificing strength. Moreover, the hypoallergenic properties of titanium make it suitable for individuals with sensitive skin. The sleek, modern designs of titanium watches provide both functionality and high- end appeal.

Brass Watches

Brass, an alloy of copper and zinc, is commonly used in watches due to its workability and resistance to corrosion. While brass watches stand out for their rich golden color and vintage appeal, common use in watch gears and internal mechanisms also attributes to its functionality. Over time, the external portion of a brass watch may tarnish and develop a patina. This offers an attractive aesthetic and a protective layer that increases the watch’s longevity. Often found in steampunk or retro designs, brass watches appeal to those who appreciate the mechanical vintage charm.

Nickel Alloy Watches

Nickel – based alloys, including copper and zinc, yield a combination of toughness and flexibility, making it ideal for various watch components. While the primary uses of nickel- enriched alloys in watches are for internal mechanisms, some exterior elements may also utilize these alloys due to their resistance to wear and corrosion. Users find these watches especially appealing due to their longevity and accuracy. However, it is important to mention that some individuals may be allergic to nickel, which occasionally limits its use in products worn directly against the skin.

Classic Analog Designs

Famous for their traditional appeal, classic analog designs extensively use alloy materials in their construction to maintain durability and give a chic look. The classic models usually have a round face, with hour and minute hands moving over simple hour markers, giving a clean and simple look. Often, the body is made of alloy steel, which protects it from rust and other kinds of damage while retaining an antique outlook. The straps on these watches are mostly made of stainless steel alloys or leather, ensuring the users have elegant designs blended with good strength for daily wear.

Sport Watches

Sport watches have come up with more alloy components in their structure because they need added strength and stay light during practice. Such watches showcase larger, more durable designs, often fitted with multiple measuring instruments such as a stopwatch or a heart rate monitor and sometimes even GPS. The cases are usually manufactured from aluminum or titanium alloys to provide toughness without adding too much weight. Many of these watches also have polyurethane straps, which are long-lasting and flexible. Wearers can work out or participate in outdoor sports without worrying about the watch's strength and functionality.

Smart Alloy Watches

In recent times, much development has occurred in this area, where watches with alloys also have the features of smart technology. Such timepieces use alloy materials to protect themselves from damage. They have Bluetooth, fitness monitoring systems, and other features, but the outside is sleek, like classic watches. Titanium and nickel alloys usually make the body light and protect it from damage. Smart watches also offer interchangeable alloy bands to match various styles, making them highly versatile for various uses and activities.

Minimalist Designs

In recent years, the minimalist trend has gained massive popularity, and these watches are made using alloy materials but with the barest and simplest of styles. These designs include plain watch faces with very few or no functions apart from the essential ones. Usually constructed with a single- piece alloy case, these watches are both sleek and sturdy as they go well with formal wear. In this style, the most prevalent materials for construction are stainless steels and titanium alloys, which provide maximum strength to the watch, hence increasing its life while still giving a modern and professional look.

Vintage or Retro Designs

Worn out and refurbished designs have alloy watches which look great, with the appeal of something old and the usefulness of something modern. Most of these styles contain design elements from the past, such as exposed gears, a leather strap, or a classical watch face, but they are made using modern alloys. Such materials as brass, copper, and stainless steel create an authentic vintage appearance and ensure great strength and no rust. Often in patina or naturally tarnished color, this kind of watch comes out with a beauty that many vintage enthusiasts and collectors will find attractive.

Custom Engravings

Personalized engravings are non- destructive modifications often made on alloy watches to increase their value as souvenirs or for individual use. Serial mark engravings, initials, or designs frequently located on the rear of the case or the strap parts are focused on enhancing the emotional connection or uniqueness of the timepiece. This engraving ensures that the exterior polish of the watch is not damaged, and it usually takes place on the scratch- resistant part of the alloy. This kind of customization makes watches a great gift or a keepsake, which adds to their value both financially and sentimentally.

Alloy Band Replacement

Changing the band on an alloy watch is one of the easiest ways to revise its exterior look. The move is usually from an alloy band to leather or fabric, which changes the watch's look, and vice versa, which is comfortable when doing outdoor sports. The modification does not damage any part of the watch so that the original band can be replaced anytime. An alloy band change is also ideal for people who want to give the old watch a new twist or make it useful in different environments.

Custom Watch Faces

Major modifications on alloy watches include the watch face or dial. Available in many colors, styles, and designs, this modification changes how time and other functions are displayed. From adding special hour markers to changing the colors or designs of the dial, there are many options for personalizing or enhancing the watch's readability. Usually, you will need special tools to change watch faces, meaning that this type of modification is usually popular with those who collect watches and people who love unique, fine accessories.

Adjustments to the Movement

Movement adjustments primarily concern precision watch movements commonly found in high- end alloy watches. These adjustments, which generally entail altering or upgrading the internal gears or adding a power reserve, increase accuracy and make the watch more valuable. Such movement modifications are done by skilled watchmakers who know watches, and it is often used by people who, as a result, want more accuracy or add to the value of luxury timepieces.

Color Coating

Color coating is a common form of modification that involves applying a thin layer of a colored substance to the surface of an alloy watch. This layer alters the original color of the watch, giving it a new vista. Usually, PVD is used in this coating, which guarantees deeper and longer- lasting color. Whether a user wants a matte black finish for a stealth look or a rose gold tint for a more luxurious appearance, coating provides a low- cost means to transform the style without changing the structure of the watch.

Shipping Methods

Shipping choices for alloy watches commonly involve air freight and sea freight. Ocean transportation is slower but rather economical, while air freight is widely accepted for time- sensitive shipments because it is fast and safe. Most alloy watches being small and light, make air freight an affordable and effective solution for getting to distant clients. Trusted packing in shock- resisting and water- resisting containers guarantees that the product arrives at its location intact and within the stipulated period.

Custom Duties and Taxes

Custom tariffs and levies are usually paid when importing watches containing alloy materials. These charges depend on the country type and the alloy watch’s value, so this should be calculated before shipping it. Certain countries apply high tariffs on luxury or electronic watches, which increases the total shipping cost. Journal import fees, companies giving watches to the dealer or wholesale buyer, look for ways to minimize or incorporate duties and taxes to keep from shocking their customers with extra charges.

Export Compliance

While sending out watches, people must also pay attention to the laws of export compliance. Export permits may be necessary depending on the destination country and regulations concerning watches with special features, such as electronic components. Such compliance ensures that exported items, including those with alloy materials, follow CITES restrictions on shipping precious metal watches. Most firms engaged in the shipping process have various legal services to guarantee smooth export operations without running into excess paperwork problems.

Packing Requirements

The packaging of watches is needed because it protects the watch and complies with shipment by law. Strong, shock- resistant packaging is required to protect the watch during transportation. Some countries include specific rules on how to pack a product to prevent it from being damaged. Watches should also have detailed information attached about what they contain so that the whole process of clearing customs becomes easy. Good packaging again adds value to the product as the buyer receives it intact and in an attractive manner.

Transit Times

Transit length depends on the method of transportation and the destination country. Air freight takes about 3 to 7 days, while sea freight takes about 7 to 21 days, depending on the location. For both methods, accurate customs clearance contributes to the arrival time. Freight companies have been selected because they provide quick and reliable transportation of alloy watches, enabling sellers to fulfil customers’ expectations regarding the product delivery date.

Watch lovers love alloy watches because they are stylish and durable. Most of the time, these are made with different types of metals, which makes them resist tarnishing, corrosion, and wear and tear. This is what makes them popular for everyday wear as well as outdoor activities. They are lighter than solid metal watches but look and feel exactly like them. This category of watches includes watches made from stainless steel, titanium, brass, and bronze. The watches have trendy finishes and hues and are strong watches.

Yes, alloy watches are tough. The alloys are made from blending two or more metals to make them stronger. For instance, watches made from stainless steel, a mix of iron and other metals, are robust watches. Titan watches are also strong but light because of titanium. This toughness means they can take everyday wear tasks and even rough handling, like environmental elements. Though they are tough and strong, some might develop scratches like any other metal.

Cleaning is simple for watches. One should avoid detergents with harsh chemicals and a lot of scrubbing. The users are advised to use warm water, a mild detergent, and a soft cloth or brush to clean them. Users should also check on the wristwatch manual for precautions while cleaning, like taking a bath or swimming in the pool or the sea.

A replacement or exchange of the band is possible. This gives a new look to the watch without causing any damage at all. One can replace it with an alloy band or a leather or nylon band for comfort. Some bands even come with easy detach and attach features so that the users can change styles depending on the occasion or outfit. It enables them to have variations in style without the need to buy another timepiece.

Usually, watches come with warranties. But customers are to register their products, and the time period varies depending on the type of watch. The warranty covers issues in the area of manufacturing and may not cover wear and tear and damage caused by poor handling. Above all, customers are advised to go through the warranty policy before any purchase.

Yes, there are many ways to customize alloy watches. Other common changes are engravings, dial, and bands. People get them to make the timepiece special or more to their tastes. Custom watches sometimes can only be made if sufficient aftermarket parts are available.