(10516 products available)

Aluminium grating is a product made of aluminum bars or strips that create a strong and open grid-like surface. This surface is used in many places where people walk, vehicles drive, or machines need ventilation. It allows light and air to pass through while being very durable.

There are different types of aluminium grating available, each designed for specific needs. Here are the main types:

Bar Grating:

This type of grating is made up of long bars arranged parallel to each other with spaces in between. The bars are crosswise woven together, creating a sturdy and stable surface. Bar grating is lightweight, corrosion resistant, and has high strength. It is used in industrial settings, walkways, platforms, and drainage areas.

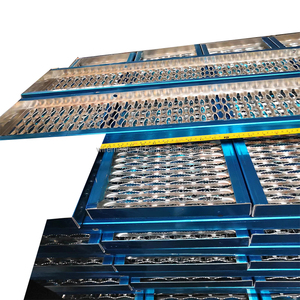

Expanded Metal Grating:

Expanded metal grating is made from a single piece of metal that is cut and stretched to form a mesh-like pattern. The pattern looks like diamonds or hexagons, depending on the design chosen. It is a one-piece construction, so there are no welds or joints that can break. This type of grating is lightweight, slip-resistant, and allows air circulation. It is commonly used for walkways, stair treads, and machine covers.

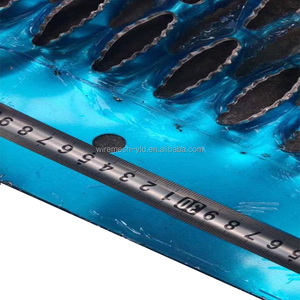

Perforated Metal Grating:

This grating is made from metal sheets that have been punched with holes in a pattern to make them lighter and stronger. The holes can be round, square, or other shapes, depending on what is needed. Perforated metal grating is very strong, durable, and has good drainage. It is used for walkways, platforms, and ventilation areas.

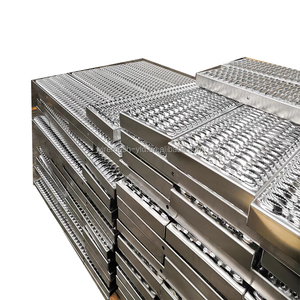

Swage-Locked Grating:

Swage-locked grating is made with aluminum bars that are locked together using a swaging machine that compresses and fuses them. The process makes a permanent and very strong bond between the bars. Swage-locked grating has high strength, is lightweight, and has no welds or joints that can break. It is used in places that need high load capacity, like bridges and heavy machinery areas.

Heavy Duty Grating:

This type of grating is made with thick aluminum bars that can support very heavy weights and loads. The bars are placed close together for strength and stability. Heavy-duty aluminum grating is super strong, very stable, and has low maintenance. It is used in industrial plants, factories, truck ramps, and areas with very high foot traffic.

Aluminum grating has various features and applications. Here are some key applications and features of aluminum grating:

Applications of Aluminum Grating

Aluminum grating is used in various industries, including:

1. Construction industry: Aluminum grating is used in the construction of walkways, platforms, and bridges. It is also used in the construction of drainage systems.

2. Oil and gas industry: Aluminum grating is used in the oil and gas industry for pipelines and storage tanks. It is also used in refineries and petrochemical plants.

3. Marine industry: Aluminum grating is widely used in the marine industry for shipbuilding and maintenance. It is also used in ports and harbors.

4. Transportation industry: Aluminum grating is used in the transportation industry for walkways, platforms, and bridges. It is also used in railway stations and airports.

5. Manufacturing industry: Aluminum grating is used in the manufacturing industry for machine parts and components. It is also used in the production of aluminum products.

Features of Aluminum Grating

1. Lightweight: Aluminum grating is lightweight, making it easy to handle and install.

2. Strong and durable: This grating is strong and durable, providing long-lasting support and protection.

3. Corrosion resistant: It is resistant to corrosion, which ensures it maintains its structural integrity in harsh environments.

4. Slip-resistant: Aluminum grating has a slip-resistant surface that provides traction and prevents accidents.

5. Customizable: It comes in various designs, sizes, and shapes that can be tailored to meet specific needs and requirements.

6. Low maintenance: Aluminum grating requires minimal maintenance, which saves time and money.

7. Fire resistant: The aluminum material used in the fabrication of this grating is fire-resistant, ensuring safety in case of fire.

Aluminum grating is used in various industries and applications for its durability, lightweight, and excellent drainage properties. Here are some common uses and applications:

Walkways and Pedestrian Paths

Aluminium grating is used in walkways and pedestrian paths in parks, industrial sites, and commercial areas. They provide safe and slip-resistant surfaces for walking while allowing water to drain through, reducing puddles and slip hazards.

Platforms and Gangways

Aluminium grating forms platforms and gangways in factories, warehouses, and outdoor spaces. They create elevated areas for workers to access machinery and areas safely while promoting airflow and light beneath.

Stair Treads and Risers

Aluminium grating makes stair treads and risers in commercial and industrial buildings. The stair treads' textured surface gives traction and prevents slips, and the open design allows for quick water drainage.

Platforms in Industrial Settings

Aluminium grating constructs platforms in factories, power plants, and refineries. They create strong and stable surfaces for workers and machinery and allow light and air to circulate, reducing heat buildup.

Drain Covers and Grates

Aluminium grating is used for drain covers and grates in urban areas, parking lots, and driveways. They cover drains and culverts while allowing water to flow freely and vehicles to pass over safely.

Utility Covers

Aluminium grating makes utility covers that protect access points to water, electricity, and sewage lines. These grates are strong enough to support pedestrian traffic and are easy to lift for maintenance access.

Parking Structures

Aluminium grating is used in parking structures and garages. They allow for effective drainage, reduce the weight of the structure, and provide slip-resistant surfaces for pedestrians and vehicles.

Commercial and Retail Spaces

In commercial and retail spaces, aluminum grating is used for exterior walkways, staircases, and display areas. Their modern look enhances the aesthetic appeal, and their durability makes them suitable for high-traffic areas.

Recreational Areas

Aluminium grating can be found in recreational areas like sports facilities, swimming pools, and gyms. They make outdoor bleachers, pool decks, and gymnasium flooring, offering slip resistance and easy drainage.

Aesthetic and Architectural Features

Aluminium grating adds aesthetic and architectural elements to buildings and structures. They are used for decorative facades, sunshades, and screening walls, combining functionality with visual appeal.

Before selecting a particular type of aluminium grating for sale, it is important to consider certain factors to ensure the product is suitable for the intended application. Here are some of them:

Consider the Application

The first thing to consider is the application for which the aluminium grating will be used. Different applications have unique requirements. For example, industrial applications require high-strength, non-slip gratings, while walkways may require lightweight and aesthetically pleasing gratings.

Check the Load Capacity

Each aluminium grating has a specific load capacity. This refers to the amount of weight it can support safely. It is important to choose a load capacity that is compatible with the intended application. Consider factors such as the number of people using the space, the weight of equipment and materials, and industry standards when choosing a load capacity.

Consider the Environmental Conditions

Aluminium grating is used in different environments, from harsh industrial settings to residential landscapes. Therefore, it is important to consider the environmental conditions where the grating will be installed. Some types of aluminium grating are designed to withstand extreme temperatures, while others can resist corrosion.

Check the Spacing Between Bars

The spacing between the bearing bars affects the load capacity and the amount of light that passes through the grating. For applications that require high load capacity, choose a grating with closely spaced bars. On the other hand, for applications that require light and air circulation, choose a grating with wider spacing between the bars.

Slip Resistance

Slip resistance is an important safety feature for areas with high foot traffic or where liquids are present. Many aluminium grating types have a surface texture that provides traction and reduces the risk of slips and falls. These include serrated and plank aluminium grating. Choose a type with a high slip resistance value for safety.

Q: What are the benefits of aluminum grating over other materials?

A: Aluminum has many advantages over other materials used for bar grating, such as steel and fiberglass. Unlike steel, aluminum does not rust. This makes aluminum grating safer for use near water and in marine environments. Aluminum is also lighter weight than steel. This can make aluminum grating easier to handle and install. Aluminum is often more aesthetically pleasing than other materials. It can be left in its natural silver color or powder coated in many different colors.

Q: What industries use aluminum grating?

A: Aluminum grating has a wide range of industrial and commercial applications. It is used in environments that require high ventilation and drainage, such as factories, power plants, and processing facilities. Aluminum grating is also used in outdoor walkways, platforms, and stair treads. It provides a clean, non-slip surface for foot traffic. Other industries that utilize aluminum grating include aerospace, transportation, water treatment, waste management, and marine.

Q: How is aluminum grating manufactured?

A: There are several ways aluminum grating can be produced. The most common methods are welding and hydraulic pressing. For welded aluminum grating, the cross bars are welded to the bearing bars to form a rigid, permanent joint. This creates a strong, durable grating. For pressed aluminum grating, the cross bars are inserted into the bearing bars and pressed together using high-tonnage hydraulic machines. This forms a friction fit joint without welding. The pressed grating is lighter and more economical.

Q: How should aluminum grating be cleaned and maintained?

A: Aluminum grating is very low maintenance. It can be cleaned with a pressure washer and soap to remove dirt and debris. In high-water areas, it is important to regularly clear the grating of any leaves or debris to prevent clogging. Aluminum should also be rinsed off if it is exposed to harsh chemicals or detergents to prevent corrosion. Once a year, aluminum grating can be pressure washed and inspected for any damaged sections that need replacing.