(343 products available)

The cement rotary kiln burner is the key part of the cement rotary kiln incineration system, and various designs exist. The main types are as follows:

Multi-Nozzle Air-Combustion Burner

This type of cement rotary kiln burner uses different nozzle angles to improve the mixing of air and fuel. The nozzles spread air in a fan-like shape. This design helps the fuel to fully burn. The result is even heat distribution inside the kiln.

Combined Secondary Air-Combustion Burners

These burners use both primary and secondary air. The primary air comes right from the fuel at the kiln's center. Secondary air is from the surrounding kiln. This burner design improves fuel burning. It also raises the temperature in the combustion zone. More heat may lead to better cement production.

Single Nozzle Air-Combustion Burner

The single nozzle burner uses a single air-combustion angle. While simpler than other designs, it still gets the job done. The single nozzle approach is easy to build and service. However, it may not evenly distribute heat inside the kiln as well as more complex burners. This design could be adequate for smaller cement plants with lower output demands.

Multi-Nozzle Air and Coal Slurry Combustion Burner

This burner is made for coal slurry fuel. It has a special nozzle design for coal slurry use. The burner improves the mixing of air and coal slurry. This leads to better combustion inside the kiln.

Cement Rotary Kiln Impingement Combustion Burner

In this burner, air and fuel mix due to kiln gas force or pressure. This design improves fuel use and lowers emissions. It also boosts kiln energy efficiency. The impingement burner adds value by using energy already found in the kiln.

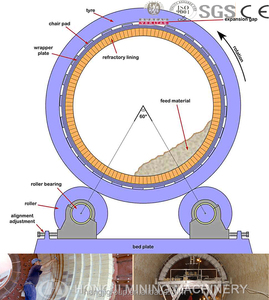

Ensuring a safe operating condition requires regular maintenance checks on the rotary cement kiln and its burners. The important components of the maintenance strategy are the inspections, repairs, frequent part replacements, and cleanings.

Scheduling routine inspections is important. With regular inspections, machine buyers could detect many small issues before they snowball into massive problems that require expensive repairs. Inspections will tip buyers off to common wear areas like roller bearings and seals, chain drive, thrust roller, gear and pinion, tire, cooling hood, feeding and discharging areas, and rotary kiln body. Choosing high-quality machines with great specifications is also a great way to limit the need for frequent repairs. Check this list of things to do to keep a rotary kiln cement machine and its burner in great shape. Also, ensure that the performing limiting and inspecting practices is in line with the manufacturers' recommendations for maximum safety and efficiency:

The primary purpose of the cement rotary kiln burner is to provide the heat required to carry out the chemical reactions in the rotary kiln for the materials being processed. Different industries use cement burners to achieve this goal in the following scenarios.

Cement industry

The cement industry is the main application field of rotary kilns. In this industry, kiln burners are mainly used to calcine raw materials such as limestone, clay, etc., to produce clinker. This clinker will be ground and mixed with additives to make cement.

Metallurgical industry

In the metallurgical industry, cement rotary kiln burners are mainly used in the fields of ironmaking and nonferrous metal smelting. For example, in ironmaking, they can be used to heat up the blast furnace or to produce direct reduced iron (DRI) in the rotary kiln. In the field of nonferrous metallurgy, they are used to calcine and roast nonferrous metal ores, which include copper ore, zinc ore, and nickel ore, etc., to process nonferrous metal ores and make byproducts. Moreover, kiln burners can also be used to handle metallurgical byproducts, such as slag and ash, through the roasting process to reduce their environmental impact.

Mineral processing

In the mineral processing industry, rotary kiln burners are mainly used to treat minerals such as limestone, dolomite, etc. They are also used to calcine various minerals and ores to carry out chemical reactions and generate valuable resources.

Glass manufacturing

In the glass manufacturing industry, cement rotary kiln burners are mainly used to melt raw materials such as silica, soda ash, etc., to produce glass products. The high-temperature environment created by the kiln burner can completely melt these materials to form a uniform glass melt, thus ensuring the quality of the glass.

Ceramics production

In the ceramics production industry, rotary kiln burners are usually used to heat and sinter ceramic products. The temperature control ability of cement burners can ensure that the ceramic products reach the desired hardness and stability through the proper heating and cooling rates.

Active lime production

In the active lime production industry, cement rotary kiln burners are the main heat sources used to calcine limestone to produce active lime. Active lime has a large number of applications in many industries, including steelmaking, metallurgy, and chemical industry, etc. Cement burners provide the heat required for this vital reaction by controlling the temperature.

Several factors must be considered to ensure effective and efficient cement rotary kiln firing systems with the help of the correct kiln burner.

Fuel Versatility:

A cement plant may use different kinds of fuels, such as alternative or less conventional fuels. Therefore, it is vital to select cement kiln burners capable of operating on various fuel types, ensuring consistent cement production.

Heat Transfer Mechanism:

A cement burner in a rotary kiln should be chosen according to the prevalent heat transfer mechanisms. For instance, the radiation or convection mechanisms may predominate in the kiln. Therefore, selecting a burner that aligns with the dominant heat transfer mechanism in the rotary kiln is crucial for optimizing energy utilization and cement quality.

Emission Standards:

Different countries and regions have distinct environmental regulations that determine emission standards. These standards can significantly impact the design and operation of cement kilns and burners. Consequently, selecting the proper cement rotary kiln burners compliant with specific emission standards is essential to minimize environmental impact and ensure regulatory compliance.

Cement Quality Requirements:

The quality of cement produced is influenced by several factors, including the composition of the raw materials, the firing temperature, and the combustion efficiency of the burner. Different types of burners offer varying combustion efficiencies and control over firing conditions. It is vital to select the most appropriate burner to meet the required cement quality and ensure optimal cement production.

Q: How does the cement rotary kiln burner work?

A: The kiln primarily uses the rotor to emit fuel and light other fuels. Additionally, it must mix other materials, such as air, for a chemical reaction or combustion to occur. Then, it can perform its task of processing materials and burning them by heat emission.

Q: What are the recent trends in cement kiln burners?

A: The augmenting requirement for alternative fuels and eco-friendly production methods in the cement industry is boosting the popularity of the multi-fuel rotary kiln cement burners. Moreover, the adoption of sophisticated emission control systems is reforming the design and functionality of cement kiln burners.

Q: How long does a cement rotary kiln last?

A: The typical lifespan of a cement rotary kiln ranges from 20 to 30 years with routine maintenance and care, although some may last up to 15 years or even up to 40 years in optimal conditions and with regular upkeep and repair.