(480 products available)

Commonly known as a CSER, the ceramic electronic spark igniter has several variations. They include;

A ceramic spark igniter has applications across various industries, from igniting burners in industrial settings to serving as a key component in gas grills and fireplaces. It has a wide range of applications that include:

Features of igniter:

Ceramic electronic spark igniters replace traditional flame-based ignition systems widely used in commercial and industrial settings. Their precise and rapid ignition, combined with durability and safety, make them ideal candidates for applications like:

Gas burners

These igniters are critical components in gas burners found in many industries, including food processing, chemical manufacturers, and metalworking. Their reliable and quick ignition minimizes the risk of gas leaks and enhances burner efficiency. These igniters are used in gas fired heating equipment, gas cooking ranges, and gas boilers, to mention a few. Additionally, in gas-fired burners, flame can be used as an indicator of burner operation. Thus, burner management systems that utilize flame detectors for safety must be integrated with igniters to facilitate burner re-ignition in case of flame failures.

Heating systems

Many heating systems, such as furnaces and boilers, use electronic spark igniters to ignite fuel for generating heat. Their reliable ignition helps ensure consistent heating and energy efficiency in residential, industrial, and commercial buildings. Moreover, electronic ignition systems eliminate the need for a pilot flame, improving energy efficiency and reducing CO2 emissions. These systems enhance the overall performance of heating appliances by replacing outdated ignition methods with modern technology.

Industrial ovens

Ovens used for baking, drying, and roasting in various production processes have their flames ignited by electronic spark igniters. These igniters provide consistent and precise ignition, critical for maintaining stable temperatures and preventing overheating. Oven applications include food processing and glass tempering. In these applications, precise temperature control is essential for meeting product quality specifications, as any deviation from required temperature may lead to defective products.

Boilers

In most cases, boiler combustion is initiated by electronic spark igniters, which generate the heat needed to ignite the fuel-air mixture. This ensures reliable boiler startup. Boiler applications include power generation and steam production. They are a necessary component in energy conversion. This shows their importance in energy production systems. At the same time, employing electronic igniters in boiler ignition enhances operational safety and minimizes emissions through efficient combustion control.

In bulk purchasing, buyers should choose commercial gas igniters based on their market needs. Buyers should also consider the following when buying igniters:

Compatibility

Buyers should consider the applications in which the spark igniters will be used. They should choose igniters that are compatible with existing systems or specific application requirements.

Igniter Design and Features

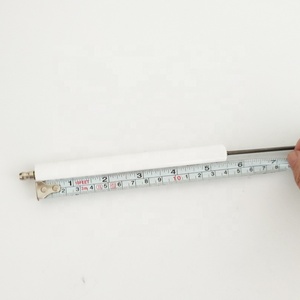

Buyers should carefully evaluate the design and features of ceramic igniters. They should consider factors like size, mounting options, and electrode configuration to ensure proper installation and integration into their applications.

Durability and Maintenance

Buyers should look for ceramic igniters that are durable and require minimal maintenance. They should choose igniters with robust construction and long-lasting performance to minimize replacement costs and reduce downtime.

Manufacturer Support and Expertise

Buyers should choose igniter manufacturers and suppliers who can provide sufficient technical support. They should ensure the manufacturer has enough experience in spark ignition technology to offer guidance on installation, troubleshooting, and optimization of the igniters for specific applications.

Regulatory Compliance

Buyers should ensure that the ceramic igniters comply with relevant industry regulations and standards. They should verify certifications and approvals to meet safety, performance, and environmental requirements of their specific application.

Ignition Performance and Reliability

Buyers should evaluate the ignition performance and reliability of the igniters. They should consider factors such as ignition energy, spark intensity, and ignition success rate to ensure consistent and effective ignition for their applications.

Cost and Value

Buyers should compare the costs of different igniters along with the value they bring. They should evaluate the overall value by considering performance, durability, support, and any additional features to ensure a worthwhile investment.

Customization Needs

Buyers should identify any specific needs or requirements. They should consider whether the igniters can be customized or tailored to suit unique applications, such as specific dimensions, electrode configurations, or integration requirements.

Q: What type of igniter is the best?

A: There is no one best igniter to use. Where one type of igniter has failed, another type has succeeded. Each type of igniter has its advantages and disadvantages. The ceramic electronic igniter is much more economical than other types, making it a preferred choice.

Q: Are spark igniters banned?

A: Spark igniters are not banned, but their use is being discouraged because they do not burn cleanly.

Q: Do all grills have igniters?

A: Not all grills have igniters. Traditionalists believe that igniters should not be used to start fires as it takes away the real charcoal burning experience. Grills without igniters depend on the user to manually light the charcoal and gas with a match or lighter.

Q: How does spark ignition work?

A: To ignite the fuel, a spark plug or an electronic ignition system generates a spark that lights the fuel. When the driver turns the key to start the vehicle, the ignition system sends a signal to the spark plugs, which then generate sparks.