(425 products available)

Ceramic firing furnaces play an indispensable role in the success of ceramic-making processes. These are heating devices used to fire and harden clay products. Depending on how the ceramic is heated, the design of the furnace also changes. There are two major categories of a ceramic firing furnace machine based on how it supplies heat: electric kilns and gas kilns. Additionally, there are many types subcategorized from the three major types discussed above, each suitable for a different ceramic product.

Electric furnace:

An electric ceramic furnace uses electricity as its main power source for firing ceramics. It is typically built with durable insulation materials and metal coils. The electric current passing through the metal coils generates heat, which is used to fire ceramic items. This item comes with different sizes, such as bench-top kilns, which are mostly used for pottery, smaller ones, or even smaller ones. No harmful gases are emitted during the firing process, making it safer for operators to use. Furthermore, the temperature control system is very precise, allowing users to set the temperature accurately. This electric firing method offers a clean energy source because it doesn't involve any form of combustion.

Top-loading electric kiln:

In this design, the firing chamber is vertical, and the user loads the ceramic item from the top. It is a compact design, and its small footprints work well for studios and light-industry spaces where floor space is limited. It is convenient to use and maneuver kiln shelves and other ceramic items inside the furnace.

Front-loading electric kiln:

This design has a horizontally opening door making it convenient to load larger ceramic items. The firing chamber is also bigger than that of the top-loading design. A front-loading electric kiln generally has a better production capacity.

Oval electric kiln:

An oval electric kiln has a unique oval shape that reduces the distance from heating elements to ceramic items. The firing time is faster, and the temperature distribution is uniform.

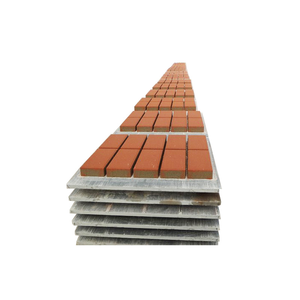

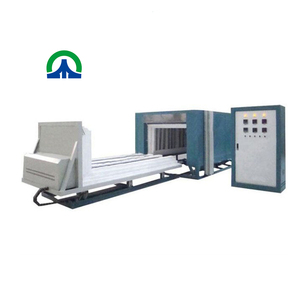

Tunnel electric kiln:

A tunnel electric kiln offers continuous firing. It's long and narrow, precisely like a tunnel. Materials line up at one end and are sequentially processed at different zones along the tunnel until they get to the other end. Operators control the temperature and other parameters in every zone. This produces consistent results. A tunnel electric kiln is usually suited for mass production.

Gas ceramic furnace:

A ceramic gas furnace uses natural gas, propane, or air, and gas mixture for oxidation firing. The gas burners built into the furnace are the heating elements. They combust fuel and produce heat, which is transferred to the ceramic items. This transfer takes place either directly or indirectly. A ceramic gas furnace provides high firing temperatures. In terms of ambiance, they are pretty hot too, and the atmosphere inside them is reducing or oxidizing, depending on the kind of gas used as fuel. The pressurized gas ignited in a gas furnace gives it higher energy output compared to electrical power sources. This makes it a great choice for industries that produce high volumes of ceramic items.

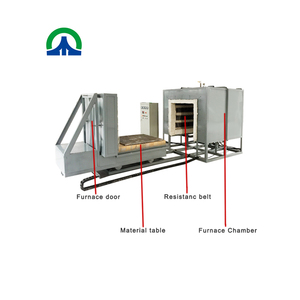

Gas shuttle kiln:

A gas shuttle kiln operates like a traditional shuttle kiln. The gas burners mounted on the back wall or side walls are the primary heating sources. The gas-equipped shuttle kiln is suitable for oxidizing firing. Its advantage is that it offers higher firing temperatures and produces less reduction compared to electric shuttle kilns. A gas shuttle kiln can be used to fire a wide variety of ceramic items, including pottery, porcelain, stoneware, and technical ceramics.

Gas reduction furnace:

A gas reduction furnace has a specially controlled reducing atmosphere. This helps to impel chemical reactions beneficial for firing particular types of ceramics. For example, the clay body may change to a different color, or the furnace may have the ability to reach higher levels of carbon in the soil, thus making it a rare find. A gas reduction furnace is also suitable for high-temperature firing. It can be used to achieve a wide range of chemical and physical changes in the fired ceramic items. The change is basically within the chemical structure of the furnace that the operator is following.

Some specifications buyers should know about a ceramic firing furnace machine are the heating power, temperature control, refractoriness, firing capacity, electricity consumption, ventilation system, safety features, and remote monitoring.

A ceramic firing furnace machine requires appropriate maintenance practices in accordance with the ceramic industry's quality requirements to ensure uniform firing and excellent product quality. This will also extend the service life of the equipment. Here are some essential maintenance tips for a ceramic firing furnace machine:

Below are some of the key usage scenarios for the firing furnace for ceramics.

Pottery and stoneware

The firing furnace is widely used in the pottery and stoneware industry to fire materials and achieve desirable properties.

Porcelain and fine china

Another common usage for a firing furnace is in the production of fine china and porcelain. The furnace is used to give the products strength and translucent feature.

Earthenware and terracotta

As expected, earthenware and terracotta ceramics products use a firing furnace for final firing. This helps to increase durability and make the products suitable for use.

Stone & glass ceramics

Typically, the firing of ceramics is common in the production of stone and glass ceramics. The firing process helps to increase the mechanical strength and resistance to chemical attack of the product.

Vitreous china plumbing fixtures

Cupboards, sinks, and toilets are examples of vitreous china plumbing devices. These plumbing ceramic products are often fired in a furnace to increase their strength and durability. Also, making the vitreous china plumbing ceramics easy to clean is one of the key use scenarios of a ceramic firing furnace.

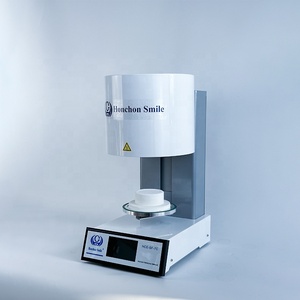

Dental ceramics

Without a doubt, dental therapy depends heavily on dental ceramic prostheses. The dental items are produced using a firing furnace. This makes it possible to shape, sinter, and glaze materials like feldspathic porcelain, zirconia, and alumina.

Firing range:

The firing range of an electric furnace for ceramics is significantly impacting the various forms that can be burnt and the attributes of the finished goods. Verify that the oven's firing range coincides with the business's requirements and the ceramics that are being utilized.

Size and capacity:

When selecting an electric furnace for ceramics, consider the size and capacity. The size and capacity must be appropriate for the business's needs, whether it involves tiny furnaces for modest batches or substantial industrial furnaces for large-scale production.

Temperature control:

It's important to examine the ceramic electric kiln's temperature regulation system. For the quality of burnt ceramics, sophisticated digital temperature controllers with precision and stability are vital. Choose a furnace with dependable temperature control that allows for precise regulation of the firing process.

Energy efficiency:

Consider the level of energy efficiency since it greatly impacts operational costs. Look at aspects like insulation, element design, and energy-saving modes that can improve the oven's efficiency.

Safety features:

Safety precautions are crucial for both the operator's safety and the risk of ceramic manufacturing. Check for things like over-temperature protection, door locking mechanisms, and safety interlocks that stop activities that could be dangerous.

Ease of operation and maintenance:

The electric kiln's usability will also be considered when choosing. The oven may be operated and maintained properly if it has a user-friendly design, clear instructions, and accessible components for cleaning and repairs.

Cost and warranty:

Finally, it's essential to balance the cost and features of the ceramic electric kiln and choose a device that meets the needs and budget. In addition, consider the warranty provided by the manufacturer, which shows the confidence in the product and provides support for any issues that may arise.

Q1: What types of ceramics can a ceramic firing furnace machine be used for?

A1: Generally, there are various types of ceramics that a ceramic firing furnace machine can be used for, including bone china, earthenware, stoneware, porcelain, and bone china among others.

Q2: What is the relationship between a ceramic's firing temperature and strength?

A2: In most cases, the strength of a ceramic material increases with higher firing temperatures. Nevertheless, this isn't a universal rule, as other factors like composition and structure play a critical role.

Q3: Can faulty ceramics be re-fired using the ceramic firing furnace machine?

A3: Sometimes, it's possible to re-fire faulty ceramics if they don't contain glazes that mature during the first firing. However, re-firing may lead to uneven results or defects.