(30175 products available)

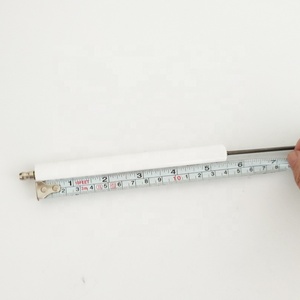

Ceramic igniters come in multiple types, and every one of them executes a unique purpose. Their tips are made of ceramic because it withstands a great deal of temperature, while their cores are made of metals, generally platinum or tungsten, which are great conductors of electricity.

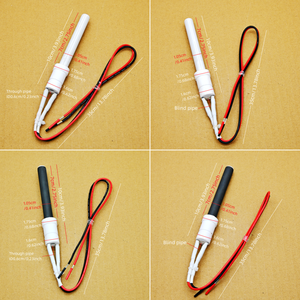

The single channel igniters have one channel; thus, they are simple and easy to install. However, this limitation means they can do one task at a time. This igniter, for instance, ignites gas burners in a very simple way.

Multi-channel igniters have several channels, thus enabling them to be used on multiple systems at a time. In complex settings, for instance, commercial kitchens where multiple burners need to be ignited simultaneously, this type of igniter becomes really handy.

It is used in environments where igniters can be damaged due to moisture. They are built with special coatings and materials and thus do not need maintenance. Their coating sometimes affects the ignition time. However, this is generally acceptable in exchange for reliability.

These devices use electrical resistance to generate heat. When the surface gets hot, it is used to ignite flames on gas burners. This is a common feature found in gas stoves, ovens, and even certain HVAC systems.

These are portable igniters that use quartz crystals. An iron hammer will strike the crystal to produce a spark. These igniters are often used on grills and camping stoves.

The choice of a ceramic igniter depends on various factors since they affect performance, safety, and reliability. Here are the criteria that one has to consider when selecting a ceramic igniter.

Different industries have different needs. Someone in the oil and gas industry, for instance, will require a high-reliability igniter for explosion risk areas. On the other hand, a residential application will probably use a less complex igniter since that is not in a high-risk area. Therefore, understanding the application requirements will guide the choice and ensure the igniter chosen meets operational needs.

There are several ways in which the ignition can be made. It can either be hot surface, for instance, where a heated surface is used for ignition, or piezoelectric shock. Choosing the type that matches firing requirements is important. For instance, piezoelectric igniters are useful in portable devices since it is shock-based, whereas the hot surface needs a power source to be maintained.

OEMs should also consider the environmental conditions. Some environments, for instance, have high humidity, where moisture can damage other parts. For these types of environments, the wet channel igniter is ideal, as it is designed for such conditions. Also, consider factors, as high temperatures might affect the performance of some igniters.

Some igniters are easier to install than others. Multi-channel igniters, for instance, can be complicated to install compared to single-channel igniters. If one is replacing an existing system, one has to make sure the new igniter will fit in the old system easily. Refitting new parts can increase the cost of the project.

When it comes to igniters, their costs vary a lot based on the type and quality. Sometimes, going for the high-priced ones could repay itself by the end in terms of reliability and lower maintenance costs. So, weigh the initial costs and the long-term benefits. Only then, one can choose the igniter that meets their budget without compromising quality and performance.

A ceramic ignition system needs to be correctly installed and maintained if it is to work well and safely. This section will explore the key installation steps and the importance of regular maintenance in preventing failures.

Below are the steps involved in the installation of a ceramic igniter:

Assessment of the Site

A detailed assessment of the site where the igniter will be installed has to be done. Factors to consider are heat intensity, gas type, and environmental conditions. When one understands these factors, they can then select an igniter that best fits the application.

Installation Preparation

After choosing the proper igniter, one needs to prepare for the installation. Gather all the required tools and equipment and clear the area where the installation will take place. Turn off the primary equipment and the relevant safety measures to prevent accidents.

Mounting of the Igniter

Follow the manufacturer's instructions to mount the igniter. Ensure it is in the correct position near the material to be ignited and that the igniter's point of emission is unobstructed. Secure the igniter so it does not move during operation.

Electrical Connections

Most igniters require power. Therefore, one has to connect the power supply following the manufacturer's guidelines. Ensure the connections are correct and that there is no risk of short circuits. Test the ignition system to confirm the igniter is receiving power.

Testing the System

After mounting and connecting, perform a test to see that the igniter functions properly. Check for flame and ask if it is steady. Also, ensure safety measures are checked and that no one is in danger during the testing.

Regular maintenance of the igniter is very important. Below are maintenance tips for ceramic igniters:

Routine Inspections

OEMs need to schedule routine inspections for the igniter. During these inspections, check for visible cracks, chip losses, or any signs of wear that could affect the performance. So doing this will allow problems to be addressed before they become serious and end up affecting production.

Cleaning the Igniter

Debris or residues accumulating on the igniter will affect its ability to generate sparks. Gently clean the igniter using non-abrasive materials. Do not use harsh chemicals, as they could damage the igniter. Also, avoid anything that could scratch the ceramics.

Testing Electrical Connections

Regularly test the electrical connections to make sure they are in good working condition. Check for loose or corroded connections because they affect the igniter's ability to generate sparks. Also, ensure there is no risk of short circuits by cleaning and securing connections properly.

Replacement of Worn Parts

Igniters wear out eventually, just like any other equipment. One has to replace the igniter when it shows significant signs of wear and tear. Actually, following the manufacturer's recommendations on the lifespan of the igniter will guide in making replacement decisions.

Keep Records

It is vital that dealers keep maintenance records. These records will help the users understand when the igniter was last inspected, how many parts have been replaced, and other useful information necessary for making informed decisions on maintenance schedules and for potential future replacements.

A ceramic heater provides the commercial value of industrial operations. It offers a reliable ignition solution in several ways. Below are the benefits that ceramic igniters provide to businesses in the area where they operate.

Ceramic igniters heat up really fast when compared to other igniters. So, the systems can start operating quickly, thus improving production and minimizing downtime. The reliable ignition ensures that operations are continuous without problems, affecting production time.

Although the initial cost of purchasing ceramic igniters could seem high, over time, their costs will be reasonable due to their durability and low maintenance requirements. They use less fuel because of their efficiency. Less fuel expenditure means savings on operational costs. In general, ceramic igniters give great returns on the investments made.

Commercial applications widely use ceramic igniters. They also work well with different fuels, whether gas, oil, or coal. This versatility makes them suitable for various industries since only one kind of igniter is required for several applications.

Safety should never be compromised. These igniters are very reliable; they do not fail to ignite easily. This means there will be fewer chances of unburned fuel accumulating in the industrial areas, which can be explosive. They are also very strong, meaning they can stand harsh working conditions. Therefore, this increases safety.

Unlike other igniters that will require frequent checks, ceramic igniters need relatively low maintenance. In most cases, they just need to be inspected periodically. This frees up the labor force so they can concentrate on other value-adding activities in the business.

These igniters are made of materials that can withstand even the highest temperatures. This makes them ideal for the harshest industrial environments. Their resistance to thermal shock is very useful. Ceramic igniters will not easily fail, as thermal expansion will cause stress on other types of igniters.

As previously stated, a ceramic igniter is a device used to ignite combustibles in industrial furnaces. It works by emitting intense heat generated by an electric current passing through the ceramic material composed of a platinum wire embedded during manufacturing. The wire heats up to extremely high temperatures, typically between 1200°C and 1300°C, and this in turn ignites the fuel or material in the combustion chamber.

Ceramic igniters are used to spark a flame in gas appliances such as furnaces, water heaters, fireplaces, and stoves. They are used in industrial equipment to provide the initial heat required to sustain combustion in processes such as metalworking, glassblowing, ceramics, and incineration.

While purchasing a ceramic igniter, the operational needs, ignition reliability, and compatibility with the existing system should all be considered. Other factors to consider include durability, the ease of installation, and maintenance requirements. These are combined with the buyer's budget so that the most suitable igniter is selected.

To improve maintenance, create a regular inspection and testing schedule and use monitoring technologies that can track performance indicators in real-time. Train staff on proper maintenance procedures and record all maintenance activities so that historical data can be referenced when needed. Also, have readily available spare parts for quick repairs or replacements.

Safety precautions for ceramic igniters include ensuring that the area around the igniter is clear of flammable materials, regularly inspecting the igniter for damage or wear, and ensuring all electrical connections are secure. Shut down the system and let cool before performing any maintenance and always follow the manufacturer's guidelines for both operation and maintenance.