(11001 products available)

A custom variator is a mechanical device that automatically changes the speed of the engine while increasing or decreasing the load. It is a crucial part of a scooter or motorcycle's automatic transmission (also known as a continuously variable transmission or CVT). The variator permits the rider to accelerate smoothly, maintain speed, and decelerate without changing gears manually. Below are some types of custom variators.

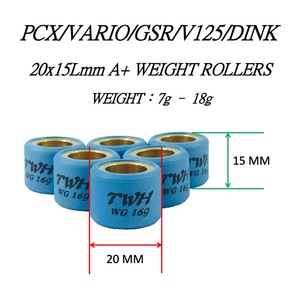

Roller Weights Variator

The roller weights variator is the most widespread and standard variator type found in many scooters and motorcycles with CVT. This custom variator uses cylindrical weights placed in a ramp slot inside the variator. As the engine RPM (revolutions per minute) increases, the weights roll outward, changing the belt's groove width. This action allows the bike to accelerate smoothly and maintain high-speed levels. Riders can customize the roller weights to suit their riding styles or performance needs. Heavier weights offer more low-end torque but reduce top-speed performance. On the other hand, lighter weights improve top speed but affect acceleration.

Sliders

Slider weights are an alternative to roller weights in the custom variator. Instead of using cylindrical roller weights, this variator employs flat, rectangular-shaped weights called sliders. The sliders ride along the ramp surface in the variator. During the CVT action, the sliders glide or slide on the ramp instead of rolling. This gliding motion results in less wear and tear on the variator components and offers a smoother transmission experience. Sliders are available in various materials, including nylon, aluminum, and ceramic. Each material provides different performance characteristics and durability levels.

Spring-Loaded Variator

Spring-loaded custom variators integrate a coil spring mechanism into the variator design. The springs apply tension to the roller weights or sliders, pushing them towards the center of the variator. This spring tension helps in providing better throttle response and low-end torque. As a result, riders experience snappier acceleration from a complete stop or low-speed cruising. Spring-loaded variators are popular among riders who prioritize performance in city traffic or off-road conditions where frequent acceleration and deceleration is required.

Adjustable Variator

Adjustable custom variators offer riders the flexibility to fine-tune the CVT system according to their performance requirements. This variator allows for changing features, such as the spring force or weight distribution, without replacing the entire component. Some models come with external adjustment ports, enabling riders to modify the settings quickly. The adjustable variator is useful for racers who need to optimize the scoot or bike's performance for specific tracks or for anyone who desires precise control over the acceleration and top-speed characteristics.

The specifications of any variator are important, and the same applies to the specifications of the custom variator.

Rollers

Rollers are an essential part of the variator, and they come in different weights. The weight of the rollers controls how the bike transmission works. When the rollers weigh more, the tension on the belt is more, and the RPM also increases. When the rollers weigh less, the tension on the belt is less, and the RPM decreases. The weight of the rollers in a custom variator impacts performance. For instance, a scooter with a 70-gram roller might go faster but use more gas. On the other hand, a scooter with a 60-gram roller may use less gas but go slower. This shows that the roller weight affects top speed and fuel efficiency.

Belt Size

The belt size is another important specification of the custom variator. The belt size determines how power gets transferred from the engine to the wheels. A scooter with a 20x 1.2cm belt will transfer power differently than one with a 24x1.4cm belt. The belt size impacts the scooter's speed and acceleration. For example, a scooter with a 24x1.4cm belt may accelerate quickly but use more gas. On the other hand, a scooter with a 20x1.2cm belt may have slower acceleration but better fuel efficiency. This shows that belt size affects power delivery.

Spring Tension

Spring tension is a specification that controls how the variator works. The spring tension decides how hard the rollers push up against the ramps. A custom variator will have different spring tensions based on the desired performance. For example, a scooter with a 1,000-pound spring will have better hill climbing than one with a 500-pound spring. The spring tension affects the scooter's torque and power delivery. A stiffer spring tension can lead to more torque, making the scooter accelerate faster. On the other hand, a softer spring tension may result in slower acceleration but better fuel efficiency.

Ramp Angles

Ramp angles control how the rollers move in the variator. The angles impact the scooter's acceleration and top speed. A custom variator can have different ramp angles. For example, a scooter with 30-degree ramp angles will accelerate quickly but have a slower top speed. In contrast, a scooter with 40-degree ramp angles may have a faster top speed but slow acceleration. This shows that ramp angles affect the trade-off between acceleration and top speed.

Aside from the specifications above, maintaining the custom variator is essential for optimal performance. Here are some tips for maintaining the custom variator:

When choosing the right custom variator for specific needs, here are some important things to consider:

Understand the Transmission Requirements

For optimal performance, it is crucial to comprehend the specifications and requirements of the transmission system. This entails taking into account aspects such as the engine's horsepower, torque ratings, and gear ratios. With this information, a variator can be chosen that is compatible with the transmission system, ensuring seamless integration and optimal performance.

Determine Riding Style and Performance Goals

Consider the riding style and performance goals. Custom variators with improved low-end torque are ideal for off-road or street riders seeking quick acceleration. Variators focused on high top-end speed suit casual street riders. Balance the needs of the rider and the vehicle to select the appropriate custom variator.

Consider Weight and Material

When selecting a custom variator, it is important to consider the weight and material of the components, as these factors can significantly influence the overall performance of the vehicle. Variators that utilize lightweight materials, such as aluminum or high-strength plastics, have the potential to minimize the overall weight of the transmission system. This reduction in weight can lead to improved fuel efficiency and enhanced acceleration capabilities. Furthermore, the use of durable materials in variator construction ensures the longevity and reliability of the components, reducing the need for frequent replacements or repairs.

Understand the Road Conditions

It is essential to take into account the road conditions when selecting a custom variator for optimal performance and durability. For instance, if one frequently drives on off-road terrain or uneven surfaces, it becomes crucial to choose a custom variator that is specifically designed to endure such challenging conditions. This ensures that the variator can effectively handle the increased stress and demands associated with off-road driving.

Evaluate Brand Reputation and Quality

When selecting a custom variator, it is crucial to consider the brand's reputation and quality. Opting for reputable brands ensures the custom variator has a superior build quality and reliability. Additionally, it is advisable to read reviews and seek recommendations from fellow riders to gain insights into the performance and durability of various custom variator brands.

Budget Considerations

When selecting a custom variator, it is essential to consider the budget. Custom variators are available in a wide range of prices, so it is important to determine the budget beforehand. However, it is crucial to remember that the most expensive option may not always be the best choice for everyone. Finding a balance between affordability and quality is key to making a satisfactory and cost-effective purchase.

Consult with Professionals or Experts

When selecting a custom variator, seeking professional or expert advice can be extremely beneficial. Experts in the field possess extensive knowledge and experience, enabling them to provide valuable guidance and recommendations. Additionally, professionals may assist in selecting the most suitable custom variator that aligns with specific needs and requirements.

Installing a custom variator is a straightforward process that can be done at home. A torque wrench and socket set, a belt tool, and a spring puller are required for the installation. The following steps should be followed:

Remove the Side Panels

Remove the screws holding the side panels using a screwdriver. The access to the transmission is provided by this step.

Drain the Oil

Drain the oil from the transmission into a suitable container. This step is important because it prevents the oil from spilling while working.

Remove the Belt

The belt is removed from the pulleys. A belt tool can be used to release the tension on the pulleys and slide the belt off.

Remove the Springs

Remove the clutch and kickstart springs from the scooter. A spring puller is needed to remove the springs safely.

Remove the Clutch

The clutch is disconnected from the crankshaft using a suitable socket and ratchet. The clutch is then removed, exposing the variator.

Remove the Variator

The variator is removed from the crankshaft using a suitable puller. This may require some force, as the variator can be stuck.

Install the New Variator

The new custom variator is installed onto the crankshaft and tightened down using a suitable torque wrench. Ensure it is properly aligned and secured.

Reinstall the Clutch

Reinstall the clutch onto the crankshaft and connect it using a suitable socket and ratchet. Ensure all bolts are tightened securely.

Reinstall the Springs

Reinstall the kickstart and clutch springs onto the scooter. Ensure they are properly seated and tensioned.

Reinstall the Belt

The belt is installed onto the pulleys, and the tension is adjusted using a suitable belt tool. Ensure it is properly aligned and seated.

Replace the Side Panels

The side panels are reinstalled using a suitable screwdriver and tightened securely. The access to the transmission is covered by this step.

Refill the Oil

The oil is refilled into the transmission, ensuring the correct level is achieved. This step is important for proper lubrication and function.

Q1: What is a custom variator?

A1: The custom variator is a variable transmission component that automates gear ratio changes, improving engine power utilization. The variator consists of two special pulleys and a connecting belt. It controls the width of the belt with the rollers to change the tension. When the vehicle accelerates, the variator automatically changes the gear ratio, ensuring that the engine maintains optimal power output.

Q2: What does a CVT custom variator do?

A2: The CVT custom variator is a transmission system widely used in modern vehicles. The custom variator allows for a smoother driving experience by providing an infinite number of gear ratios that adjust seamlessly according to driving conditions. The CVT custom variator improves fuel efficiency and engine performance by keeping the engine in its power band.

Q3: What is the difference between a variator and a gearbox?

A3: The custom variator differs from traditional gear systems. While the latter uses fixed gears to change speed and torque, the custom variator allows for automatic and smooth transitions between different ratios. This provides better acceleration and fuel efficiency, making it popular in modern vehicle designs.

Q4: What are the maintenance tips for the variator?

A4: Maintaining the custom variator is crucial for optimal vehicle performance. Regularly changing the transmission fluid is vital, as it lubricates the variator components and prevents wear. Avoid sudden acceleration and overloading the vehicle, which strains the variator. Following the manufacturer's maintenance schedule is essential to ensure the custom variator's longevity and reliability.