Cutter Gearbox: The Heart of Efficient Cutting Mechanisms

The cutter gearbox is an essential component of various machinery used in construction, agriculture, and manufacturing. It plays a critical role in transferring power from the motor to the cutting implements, ensuring smooth operation and precise cutting. Understanding the nuances of cutter gearboxes can significantly enhance machinery performance, prolong lifespan, and optimize maintenance schedules.

Types of Cutter Gearboxes

- Helical Gearboxes: Designed for high efficiency and quiet operation, helical gearboxes mitigate vibration and wear, making them ideal for constant and dynamic operations.

- Bevel Gearboxes: Used to transmit power between shafts that are at right angles, bevel gearboxes provide versatility in machinery design, particularly in compact spaces.

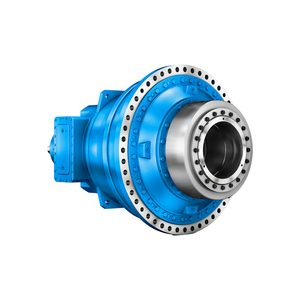

- Planetary Gearboxes: Known for their compact size and high torque output, these gearboxes are perfect for applications requiring a high degree of power transmission in a reduced footprint.

- Worm Gearboxes: Offering excellent reduction ratios and the ability to handle heavy loads while maintaining low speed, worm gearboxes are suited for applications where compact size and reduced input speed are pivotal.

Function, Feature, and Design of Cutter Gearboxes

- Power Transmission: Cutter gearboxes efficiently transfer rotational energy from the motor, adjusting speed and torque to the cutting tools.

- Durability: Typically constructed from hardened steel, cutter gearboxes withstand high operational loads and stress, contributing to long-lasting performance.

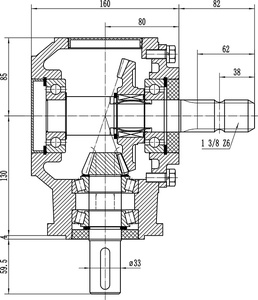

- Compact Design: Most cutter gearboxes are designed to fit within tight spaces, optimizing equipment layout while ensuring accessible maintenance.

- Low Noise Level: Many modern cutter gearboxes are designed to operate quietly, enhancing the working environment in various applications.

Applications of Cutter Gearboxes

- Agricultural Equipment: Cutter gearboxes are commonly found in combines, mowers, and tillers, where they play a vital role in effectively processing crops.

- Manufacturing Industries: Heavy-duty cutters in manufacturing rely on robust gearbox systems to ensure precision cutting in various materials, from metals to plastics.

- Construction Machinery: In equipment like excavators and trenchers, cutter gearboxes facilitate effective earthmoving and material handling.

- Woodworking Machines: Applications such as sawmills and routers require precise cutter gearboxes to achieve intricate cuts and finishes in timber processing.

Advantages of Using High-Quality Cutter Gearboxes

- Enhanced Performance: Investing in quality cutter gearboxes ensures optimal machine operation, leading to better productivity and efficiency.

- Improved Longevity: Durable gearboxes reduce the need for frequent replacements, thereby lowering operational costs over time.

- Customization Options: Various designs and specifications mean that cutter gearboxes can be tailored to meet the specific requirements of diverse applications.

- Maintenance-Friendly: Features like easy lubrication access points and robust designs result in reduced downtime and ease of maintenance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4