(467 products available)

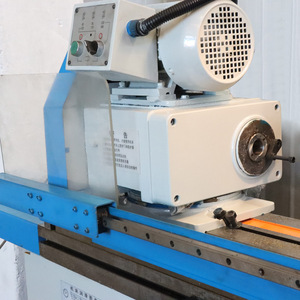

A cylindrical grinder small is a machine used to grind and trim round or cylindrical objects. The cylindrical grinders are available in small portable and larger industrial-scale versions. These machines hold the workpiece in a fixture and rotate it. A stationary cutting tool then trims the workpiece into various shapes.

Small benchtop cylindrical grinders are popular in DIY and small workshop settings because of their small size and portable nature. They are usually placed on the workbench to save space and make it easier to work with cylindrical objects. Small cylindrical grinders can be used for light-duty grinding, shaping, and sharpening of wood, metal, plastic, pipes, and other materials.

Tool post grinders are used in metal lathes and installed on the tool post of a metal lathe machine. They are mainly used to improve the quality of the finish on rough turned parts, reduce radii, deburr parts, and perform other light grinding operations. Their mounting system and alignment with the lathe spindle make them easy to use.

Automated cylindrical grinders use computer numerical control (CNC) or automation to simplify the grinding process. They are more efficient than manual cylindrical grinders and help reduce operator fatigue. Automated cylindrical grinders also improve the product's quality and consistency. Some common features of cylindrical grinders include preset programs, remote control, an integrated database, and a touchscreen interface for easy operation and supervision.

Portable cylindrical grinders are designed for easy handling and transport. They usually feature a sturdy but lightweight frame, an ergonomic handle, and a compact design. Their portability allows users to work on cylindrical objects in hard-to-reach places and outside the workshop. Some examples of portable cylindrical grinders include electric, pneumatic, and angle grinders.

Specification:

It is very important to maintain grinding machines so they can work properly, safely, and for a long time. Manufacturers of small cylindrical grinders usually include a maintenance schedule in their instruction manuals. This schedule shows what needs to be done and when to do it. Here are some general maintenance tips for small cylindrical grinders:

Cylindrical grinders are useful in various industries, such as automotive and metalwork, small and large sizes. A small grinder machine offers even more versatility when it comes to use.

A cylindrical surface grinder can put the following parts through the grind:

These are just some examples of the countless possibilities that cylindrical grinders offer. Smaller grinders can further multiply these use cases, as demonstrated below.

Small cylindrical surface grinders are ideal for use on smaller parts such as these:

Assess grinding needs and capacity requirements

When choosing a small cylindrical grinder, it's important to first determine the grinding needs and capacity requirements. What type of materials will be ground? Will the grinder be used for producing large quantities or smaller batches? The answers to these questions can help in selecting a grinder with the right grinding specifications and capacity.

Consider space limitations and machine size

For those with limited workshop space, the size and footprint of the cylindrical grinder are key factors. Ensure that the chosen grinder will fit in the available space, and consider its weight to check if any lifting equipment is needed for installation. Also, think about the layout of the workshop and where the grinder will be positioned in relation to other machines and workstations.

Evaluate power requirements and electrical supply

It's crucial to evaluate the power needed for grinding operations and the electrical supply in the workshop. Check that the electrical supply can safely handle the power requirements of the grinder without overloading circuits. Sufficient power is important for the efficient functioning of the grinder.

Assess safety features and ergonomics

When choosing a cylindrical grinder, it's important to look at the safety features and ergonomics of the machine. Safety must be a top priority, so check for things like emergency stop buttons, proper guarding, and anti-vibration pads. At the same time, consider the ergonomics of the grinder. This includes how easy it is to access grinding parts, control positions, and whether the working heights are suitable.

Research reputable manufacturers and suppliers

It's a good idea to take the time to research and pick trustworthy manufacturers and suppliers of small cylindrical grinders. Spending some time on this step can eventually lead to a better decision. Choose well-known brands in the industry who are recognized for their quality products. Also, consider suppliers that are able to offer a wide selection of grinders to meet different needs.

Q: What is the difference between inside and outside diameter grinding?

A: Outer diameter grinding involves holding the workpiece on its external surface, while inner or internal diameter grinding works on the inside surface of a hollow cylindrical workpiece.

Q: What materials can a cylindrical grinder small work with?

A: Common material such as cast iron, steel, stainless steel, alloy steel, and tool steel. While these materials are typical, the specific chemistry and hardness must align with a particular cylindrical grinder small's capabilities to ensure effective machining.

Q: Can a cylindrical grinder small machine achieve the same level of precision as larger models?

A: Yes, many small cylindrical grinders can achieve high precision and tight tolerances comparable to their larger counterparts. However, the grinding capacity may be limited.

Q: How does one ensure safety when operating a cylindrical grinder small machine?

A: Always wear appropriate personal protective equipment (PPE), including safety glasses and hearing protection. Additionally, familiarizing oneself with the machine’s manual and ensuring all safety guards are in place before operation is crucial.