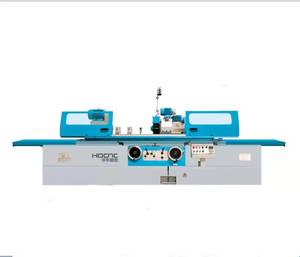

Cylindrical Grinding Machine Grinder: An Overview

The cylindrical grinding machine grinder is an essential tool in the manufacturing and metalworking industries. This robust equipment is designed to produce high-precision cylindrical parts by grinding their outer surface. Whether you need to achieve a smooth finish or precise dimensions, these grinders are crucial for meeting stringent quality standards. Their versatility makes them suitable for various materials and applications, ensuring that businesses can maintain optimal production efficiency.

Types of Cylindrical Grinding Machine Grinders

Cylindrical grinding machines come in several types, each designed to cater to specific grinding tasks. Understanding these types can help in selecting the right machine for your project:

- External Cylindrical Grinders: These machines focus on grinding the outer surface of cylindrical parts. They often feature basic support for the workpiece and can handle various sizes.

- Internal Cylindrical Grinders: Designed for processing the internal surfaces of cylindrical parts, these grinders allow for precise machining of hollow components.

- Universal Cylindrical Grinders: These machines combine both internal and external grinding capabilities, making them incredibly versatile for various applications.

- Roll Grinders: Tailored for the grinding of heavy workpieces like rollers, these machines are built with robust frames and high-precision technologies.

Applications of Cylindrical Grinding Machine Grinders

The cylindrical grinding machine grinder has wide-ranging applications across different industries, showcasing its importance in the production process:

- Aerospace: Used for precision components such as turbine shafts and landing gear parts, ensuring high-quality standards.

- Automotive: Essential for manufacturing gearbox shafts, valve guides, and other engine components that require exact dimensions and finishes.

- Tool Manufacturing: Ideal for creating cutting tools, punches, and dies, where accuracy is critical for functionality.

- Medical Devices: Employed in the production of implants and surgical instruments, where precision and reliability are paramount.

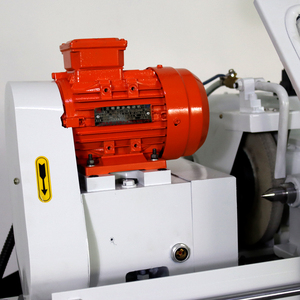

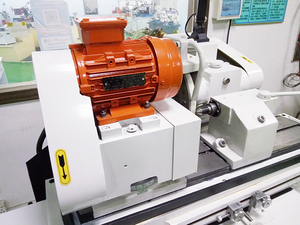

Features of the Cylindrical Grinding Machine Grinder

Cylindrical grinding machines are equipped with a range of features that enhance their functionality and ease of use:

- Precision Control Systems: Many models come equipped with advanced CNC (Computer Numerical Control) systems that allow for automated and highly precise adjustments.

- Versatile Grinding Wheels: These grinders accept various wheel types, enabling operators to switch out wheels to achieve different finish qualities for different materials.

- Effective Cooling Systems: Integrated cooling mechanisms help maintain optimal temperatures during grinding, reducing wear on the machine and enhancing surface finish quality.

- Flexible Workholding Solutions: Adjustable clamps and supports accommodate a range of workpiece sizes, enhancing versatility and efficiency during operations.