(15067 products available)

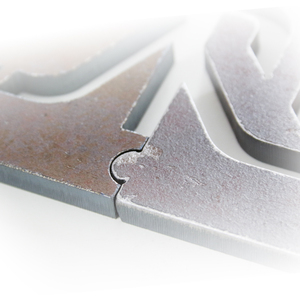

Several manufacturers make many kinds of deburring machines for various use and materials. They all have a wide range of applications, from metal to ceramics, plastic, and glass. Here are some types of deburring machines made by these manufacturers:

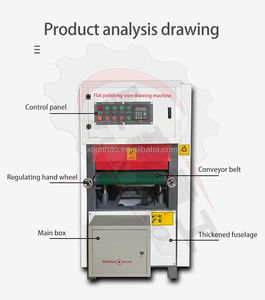

Machine size and weight

Deburring machines typically range in length, width, and height. The dimensions of a burr-removal machine vary based on its category, model, and specifications. The weight also varies, with smaller machines weighing about 100 kgs and larger, industrial-scale burr-removal machines up to several tons.

Workpiece size and weight

Some burr-removal machines can process workpieces that are up to 1,000 mm wide. The maximum weight a deburring machine can handle determines its production capacity.

A machine that can remove burrs from metal parts weighing up to three kg can deal with at least 13 kg in the case of a heavy-duty machine. Workpiece shapes also differ, and the more complex the shape, the more difficult it is for the burr-removal machine to do its job.

Power and speed

Deburring machines usually have electric motors with a few kWs of power. However, heavy-duty machines can have up to 20 kW of power. A machine's speed in deburring workpieces is also an essential specification. Heavy-duty burr-removal machines that operate more efficiently with hardened steel are ideal for industrial-scale production.

Bonded abrasives

Deburring machines use bonded abrasives made from a mixture of an abrasive and a polymer, typically used for non-metallic materials. These abrasives may have different sizes and shapes, allowing them to adapt to the particular geometry of the workpiece.

Amplitude and RPM

Deburring machines usually have a frequency inverter that changes the number of revolutions per minute of the rotating tool. The amplitude refers to the oscillation width of the finishing media when working on a workpiece. Some machines can operate within an amplitude of about 2 to 4 mm. Amplitude and RPM affect the time it takes to deburr an object and the smoothness of the finish.

Power source

Deburring machines are usually powered by electricity, and their power requirements are indicated in kilowatts.

Proper maintenance of a deburring machine is important for optimal machine performance, safety, and production efficiency. Following standard operating procedures ensures the machine deburrs more efficiently, prolonging its service life.

It is crucial to operate the appropriate abrasive media for the material to be deburred. The burr-removal process is more efficient and cost-effective when the suitable media are used.

Regularly checking the working surface of the machine helps identify water and oil leaks and allows users to notice abrasion or damage early. Key parts, including change belts and chains, should be lubricated regularly.

Proper training on operating the machine helps prevent accidents and damage to the cylinder.

Inspect the dust collector pipeline for blockages at least once a month to prevent debris build-up. The pipeline should be cleaned to ensure safe operation and a healthy working environment.

Industrial deburring machines are essential pieces of equipment used in industries with an extensive manufacturing sector. This includes the construction industry in which metal alloys are often used to make equipment and structures like bridges. In the woodworking industry, this machine is used to smooth out metal parts of equipment and instruments used to handle and work with wood.

Manufacturing industries that work with metal components and parts need to have a deburring machine handy. This applies to the automotive industry, where precision is paramount. Car parts need to be free of any sharp edges to ensure a secure and comfortable fit. The same applies to the aerospace industry. Alloys and metals used to make aircraft need to be free of rough edges and burrs to ensure smooth and secure assembly and a lightweight build.

Jewelry manufacturers can also benefit from the smoothening effects of deburring machines. Jewelry made of gold and silver will often have sharp edges and rough spots that customers won’t appreciate. Using a deburring tool or machine can help to smooth out these rough areas and make the jewelry piece more presentable.

Small to medium-scale metalworking operations will also be familiar with this machine. Workshops that are used to cut, shape, and weld metals need a method of finishing these parts. A deburring machine can help to reduce the manual labor required to smooth rough and sharp edges.

Wholesale buyers must consider several factors when selecting a deburring machine for their lines, as outlined below:

Material Compatibility

Ensure the machine can handle the specific materials, metal composites, and plastics used in production. Consider factors like material hardness, thickness, and shape. If dealing with multiple materials, assess machines with flexible toolings or adjustable settings to accommodate various compositions.

Burr Types

Consider the specific types of burrs that need removal. Different machines excel at addressing particular burr types—for instance, rounded chamfers, grooves, threading holes, or inner/outer edge burrs. Select a machine designed for the predominant burr types encountered to ensure effective removal and avoid costly rework.

Production Volume

Consider the amount of parts produced each day and how quickly they must be deburred. For high-production volumes, look at machines that handle a large number of parts continuously. Machines with automation and higher speeds typically cost more, so balance the expense against their capacity to meet the required production line demands without bottlenecks.

Precision Requirements

The level of precision required in the final product will determine the type of deburring machine needed. For applications where aesthetic and functional perfection is paramount, a machine capable of achieving micron-level precision should be considered, even if it comes at a higher cost. Investing in a precise model from the start can prevent the need for subsequent rework and help maintain high-quality standards.

Budget Constraints

When selecting a deburring machine, it's important to consider upfront cost, operating expenses, and maintenance needs over the entire machine’s lifetime. While a particular model may be more affordable initially, lower durability could result in higher ongoing costs due to frequent repairs. Striking an ideal balance between initial price and long-term expenditure is essential for a prudent investment. Prioritize models renowned for reliability and efficient design to minimize future expenses and maximize value.

Q1. How does a deburring machine work?

A1. Deburring machines remove burrs from workpieces by applying a cutting tool, abrasive media, or an electron flow. The burrs are either cut off, sanded down, or dissolved with the methods mentioned.

Q2. How does a digital deburring machine differ from traditional ones?

A2. Digital deburring machines allow for programmatic control of the deburring process, enabling precise adjustments, automation, and data logging. This contrasts with traditional machines that offer manual control and limited operational flexibility.

Q3. Can a deburring machine be used on all materials?

A3. No, manufacturers need to assess the suitability of the deburring machine for a particular material type, shape, and size. While most metals, plastics, and wood can be deburred, some delicate natural materials, like ceramics, may not be suitable.

Q4. Can a deburring machine also be used to polish?

A4. Some deburr machines can also polish workpieces to a shine. However, manufacturers must verify if the intended machine can do both without compromising effectiveness.