Introduction to Factory CNC Grinder Machine

The factory CNC grinder machine is an essential piece of equipment in manufacturing and machining sectors, specifically designed to provide precision surface grinding. This state-of-the-art machine utilizes advanced Computer Numerical Control (CNC) technology, enabling it to achieve remarkable accuracy and repeatability. It is a valuable tool in a variety of industries, from aerospace to automotive, where precision engineering is paramount.

Types of Factory CNC Grinder Machines

Factory CNC grinder machines come in various types, each engineered to cater to specific grinding needs:

- Surface Grinders: Ideal for flat surfaces, these machines are perfect for creating a smooth finish on metals and other materials.

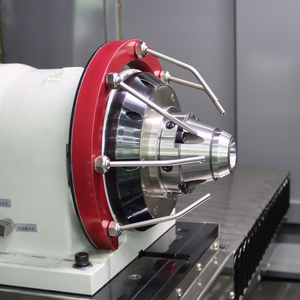

- Cylindrical Grinders: Used for grinding the outer and occasional inner surfaces of cylindrical objects; key for producing axle components and other round parts.

- Centerless Grinders: Designed for high-volume production, they handle multiple items simultaneously, ensuring efficiency in bulk grinding processes.

- Universal Grinders: Versatile and adaptable, they can grind various shapes and projects, making them a staple in multi-purpose workshops.

Features and Applications of Factory CNC Grinder Machines

The features of factory CNC grinder machines offer vast applications throughout different sectors:

- Precision Engineering: CNC technology allows for intricate designs and patterns that require exact measurements, ideal for manufacturing delicate components.

- Automated Processes: Automation in grinding processes reduces human error, increases productivity, and saves labor costs.

- Software Integration: Many CNC grinders are compatible with CAD/CAM software for efficient design execution, improving workflow and project adaptability.

- Material Versatility: Capable of grinding metals, plastics, and ceramics, these machines cater to numerous industries with diverse materials.

Advantages of Using Factory CNC Grinder Machines

The leverage of technology in factory CNC grinder machines yields multiple benefits:

- Enhanced Precision: The use of CNC reduces the tolerance levels in machining, ensuring that every piece meets industry standards.

- Increased Efficiency: With quicker setup times and a continuous operation without the need for frequent human oversight, production speeds are markedly higher.

- Cost-Effectiveness: Although the initial investment may be higher compared to manual machines, the long-term savings on labor and material waste make them more economical.

- Improved Safety: Automated systems reduce worker exposure to dangerous conditions, ensuring a safer working environment and minimizing the risk of injuries.