(2465 products available)

A granules mixer machine helps in uniformly mixing granules of different colors. Also known as the color blending mixer or granules blender, there are many ways to use a color mixer machine for granules. The primary methods include V-shaped mixers, horizontal ribbon mixers, octagonal mixers, and double-cone mixers.

V-Shape Mixer

The V-shaped mixer is commonly used in the pharmaceutical and food industries. It easily mixes products without having any adverse effects on their quality. The machine has two distinct vessels that are connected to each other. One side is wide, while the other is narrow, forming a shape of the letter 'V'. When the vessel spins, the granules move around and get mixed up. The blending process is very gentle. Therefore, it doesn't break, damage, or degrade any food or medicine components.

Horizontal Ribbon Mixer

Jacketed ribbon horizontal mixers are used for diverse products and industries. The mixing happens through ribbons that are fixed on a rotating shaft. These ribbons push the materials in opposite directions, leading to a well-mixed final product. The ribbon blender can process a large number of materials at once. But due to the high shear, it is better suited for industries like plastics and chemicals.

Some horizontal ribbon blenders also come with a jacketed feature. This means they have a space between the outer shell and the inner blender. The blank space can be filled with water or ice. The cooling or heating happens through conduction and can maintain or change the temperature of the material inside.

Octagonal Mixers

The machine has an eight-sided vessel. Hence, the name 'octagonal.' The unique blend shape helps move and lift the materials better than most mixers. Also, since there are no dead zones in the vessel, the final product is homogeneous. In the end, the final mixture looks like a powder.

Double Cone Mixer

The shape of the double cone mixer looks like a cone on two sides. It is one of the most popular machines to mix different-colored granules. The machine rotates. As it rotates, the granules are mixed up. The moving cone also flows the material in different directions. The machine can mix all kinds of dry solids. But the mixer is not ideal for working with liquid or paste-like materials.

The application of granules mixer machine is quite widespread in many industries. In the food industry, it is used to mix the colors of various food items such as candies, M&Ms, pet food, and others. Additionally, it's used to mix and develop flavors and fragrances in the processing of chemical products.

Granules color mixer machines can be found in the following industries:

Food processing

In the food industry, color mixers are used to create uniform and consistent colors in various food products, such as confectionery, snacks, and baked goods. They ensure that the food products have visually appealing colors that enhance the quality and marketability of the products.

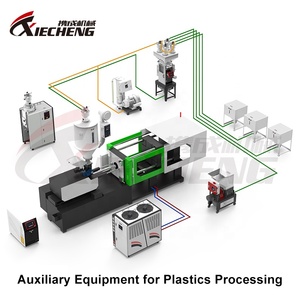

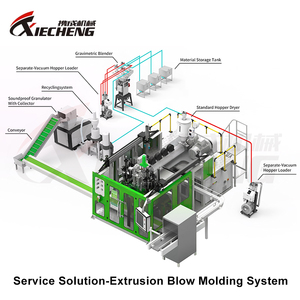

Plastics manufacturing

Granules color mixer machines are widely used in the plastics industry to uniformly mix color additives, masterbatches, and polymer resins. They ensure that plastic products, such as containers, automotive parts, and consumer goods, have consistent and vibrant colors throughout.

Coatings and paints

In coatings and paint production, color mixers are used to achieve consistent color dispersion in paints, varnishes, lacquers, and coatings. They ensure that the final products have uniform colors, which is crucial for decorative, industrial, and automotive applications.

Rubber and polymer compounding

Granules color mixers are used in rubber and polymer compounding to achieve uniform color distribution in rubber products, such as tires, seals, and gaskets. They ensure that the colored rubber products meet aesthetic and performance requirements.

Masterbatch production

Masterbatch manufacturers use granules color mixers to produce color masterbatches, which are concentrated color formulations used to color various plastic products. Color masterbatches offer advantages such as easy handling, storage, and addition to polymer matrices.

Consider the following critical factors to help choose the proper mixer Granules in any application:

Production capacity

Granule mixers have varying production capacities. Determine the quantity of product needed per hour or per batch to meet demands. It's essential to select a mixer that has the capacity to handle the required volume while maintaining efficient mixing.

Mixing technology

Granule mixers employ different mixing technologies, such as paddle mixing, ribbon blending, vibrating and fluidized bed mixing. Consider the advantages and drawbacks of each method to select the one that best suits specific needs in terms of mixing efficiency, uniformity and product integrity.

Dust control features

Dust generation during granule mixing can pose health risks and safety concerns. Look for mixers equipped with effective dust control features, such as extraction systems or sealed containers, to minimize particulate exposure and maintain a clean working environment.

Material compatibility

Different machines are designed to handle specific types of granular materials. Consider the material compatibility of the mixer, including factors like friction resistance, corrosive properties and temperature limitations. Choose a mixer that can handle the specific materials used to ensure optimal performance and avoid damage.

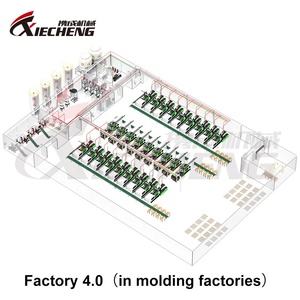

Production line integration

In some cases, mixers need to be integrated into existing production lines or coupled with other processing equipment. Consider the production line integration capabilities of the mixer, such as its dimensional suitability and compatibility with automated systems. Ensure it can be smoothly integrated to maintain operational efficiency.

Q1: What are the mixing methods used by granules color mixer machines?

A1: Granules color mixer machines typically use two mixing methods: layered mixing and diffusion mixing. The latter involves relocating granules from different layers to various sides, while the former involves moving granules in different directions.

Q2: What are the safety precautions when using a granules color mixer machine?

A2: Operators should ensure the machine is properly grounded to prevent electric shocks. They should avoid inserting hands or tools into the mixing chamber while the machine is running. Operators should also wear appropriate PPE, including eyewear and masks, and avoid overloading the mixer.

Q3: Can a granules color mixer machine work with liquids?

A3: Generally, granules mixers are designed to work with dry materials. Mixing liquids with powder could damage the machine or create safety hazards.

Q4: How long does it take for a granules color mixer machine to blend materials?

A4: The mixing time varies depending on the model, quantity, and type of materials. However, some high-efficiency granules mixers can blend materials in one to five minutes.

Q5: Can users add more colors to a mixed product after using a granules color mixer machine?

A5: Yes. Customers can add more colors and mix the products again to achieve the desired color specification.