(184786 products available)

High RPM refers to high revolutions per minute in vehicles, and its types are as follows.

High-RPM Engines

High-RPM engines, also called high-speed engines, are internal combustion engines designed to operate at high rotational speeds. These engines have several features that enable them to achieve and sustain high RPM levels:

1. Valve Train: High-RPM engines often have a robust valve train system with lightweight components like aluminum or titanium valves and retainers. These materials reduce the mass of the valve train, minimizing valve float at high RPM and allowing for precise valve timing.

2. Camshaft: Camshafts in high-RPM engines are designed with profiles optimized for high-speed operation. These camshafts control the timing and duration of valve openings and closings, allowing for better airflow at elevated engine speeds.

3. Induction System: High-RPM engines typically have advanced induction systems that enhance airflow into the combustion chamber. Upgraded air intakes, larger throttle bodies, and high-performance turbochargers or superchargers can induce more air, supporting combustion at higher engine speeds.

4. Exhaust System: High-performance exhaust systems with fewer restrictions and improved airflow characteristics are also used in high-RPM engines. These exhaust systems help expel exhaust gases more efficiently, reducing back pressure and supporting higher engine speeds.

5. Lubrication: High-RPM engines require effective lubrication to minimize friction and wear on moving parts. Advanced lubrication systems with high-quality engine oil and oil coolers are often used to maintain optimal oil temperature and flow, even at high speeds.

6. Cooling: Cooling systems are critical in high-RPM engines to dissipate heat generated during high-speed operation. Upgraded radiators, higher-capacity water pumps, and cooling fan systems are commonly used to maintain the engine's temperature within acceptable limits under high-RPM conditions.

High-RPM Tools

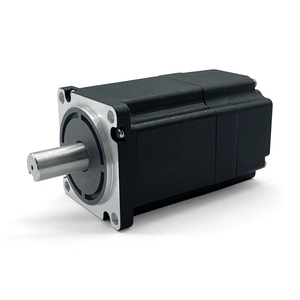

High-RPM tools are electric or battery-operated tools that perform a specific task at a high number of revolutions per minute (RPM). The tool's motor is designed to have a high torque output, allowing it to spin attachments or bits at high speeds. These tools also have a cooling system to prevent overheating from prolonged use at high RPM.

The specifications of high-RPM machinery and parts may vary depending on the type of product and the needs of the end-users. Here are some general specifications to expect:

Speed rating

High-RPM parts have a high speed rating. This is the maximum speed the part can achieve under normal usage. The rating is given in revolutions per minute. For instance, high-RPM motors may have a speed rating of 6000 RPM or more.

Torque

Torque refers to the twisting force the part creates. High-RPM parts have a lower torque than low-RPM parts. This is because the part relies on its speed to create the necessary force. Torque is measured in Newton-meters (Nm) or pounds-feet (lb-ft). For instance, a high-RPM motor may have a torque of 10 Nm.

Power

High-RPM parts use more power than low-RPM parts. This is because the part relies on its speed to create the necessary force. Power is measured in watts (W) or horsepower (HP). For example, a high-RPM motor may have a power of 100 W.

Bearings

High-RPM components use specialized bearings to reduce friction and support the part's weight. The bearings are designed to handle the high speeds and loads associated with high-RPM parts. For example, high-RPM motors may use ball or roller bearings.

Cooling

High-RPM parts generate a lot of heat due to the high speed and friction. Cooling systems, such as fans or water cooling, are used to dissipate the heat and maintain the part's optimal operating temperature. Cooling is especially important in high-RPM engines and industrial machinery.

High-RPM parts need regular maintenance to keep the specified standards. The following are some general maintenance requirements:

Lubrication

High-RPM parts require regular lubrication to reduce friction and wear. Use lubricants with the right viscosity to reach all the part's moving components. Follow the supplier's recommendations on the right type and interval of lubricant application.

Tightening

Check and tighten any loose fasteners, such as bolts and nuts, on the high-RPM part. Vibration and the high speeds can cause these fasteners to become loose over time, affecting the part's performance and safety.

Cleaning

High-RPM parts can accumulate dirt, dust, and debris from the environment or the part's operation. Regular cleaning using the right procedures and products is important to maintain the part's performance and prevent damage.

Inspect

Conduct regular inspections of the high-RPM part to check for signs of wear, damage, or other issues. Address any problems quickly to prevent further damage or failure of the part.

Choosing the right high rpm machinery or equipment is essential for business operations. Here are some tips on how to choose high RPM equipment:

Understand the application

Before choosing high-RPM machinery, it’s essential to understand the application it will be used for. This will help in understanding the equipment that will be suitable for the application. For example, if the machinery is used in the manufacturing process, the equipment should be able to handle the manufacturing processes effectively.

Quality and durability

Durability and quality are important factors to consider when choosing high-RPM equipment. The equipment should be made from quality materials that can withstand the application and the operation. This will ensure that the machinery can last for a long time and reduce the downtime of the business.

Maintenance

High RPM equipment requires regular maintenance to ensure that it is in good condition and to avoid wear and tear. Therefore, maintenance is an important factor to consider when choosing high-RPM equipment. Choose equipment that can easily be maintained and spare parts that are easily accessible.

Cost

Cost is an important factor to consider when choosing high-RPM equipment. Choose equipment that is within the budget of the business. However, it is important not to compromise the quality of the equipment.

Energy efficiency

High-RPM equipment consumes a lot of energy; hence, choosing energy-efficient equipment is important. This will help the business save energy costs.

Safety

Safety is an important factor to consider when choosing high-RPM equipment. The equipment should have safety features to protect the workers from injuries. Also, the machinery should meet the industry safety standards.

Portability

Consider high-RPM equipment that is portable and can easily be moved from one place to another. This is important, especially in applications such as agriculture, where the equipment needs to be moved from one field to another.

DIYers need to understand the importance of proper troubleshooting before attempting to replace High-RPM parts. This is because, without knowing the exact cause of the problem, they might end up replacing the right part of the engine or car and still not solve the problem.

That said, if it is something that can be replaced easily like a High-RPM thermostat or the High-RPM gauge, then it can be DIY. Replacing the high RPM gauge requires a 3/8 socket, 1/4 drive ratchet, and a high RPM gauge kit. Remove the dash panel, unplug the old gauge, plug in the new gauge, and the job is done.

Replacing the thermostat requires a half-inch ratchet, 13 mm socket, 10 mm wrench, and a new thermostat. It's advisable to drain some coolant before starting the job. Locate and remove the thermostat housing, then remove the old thermostat and replace it with the new one.

Before starting any DIY project on a vehicle, it is important to read and understand the service repair manual for that particular vehicle. The manual provides step-by-step instructions on how to locate and replace a specific part of the vehicle.

For parts that are difficult to replace, such as the engine control module, ignition coils, and spark plugs, it is better to call a professional mechanic.

Q1: What cars have high rpm?

A1: Generally, sports cars have high RPM. For example, the Ferrari 488 GTB has a maximum speed of 8,000 RPM. In addition to sports cars, some high-performance muscle cars also have high RPM. For example, the Ford Mustang GT has a maximum speed of 7,500 RPM.

Q2: Do high rpm cars require special oil?

A2: High RPM cars do not necessarily require special oil. However, many high-RPM engines use synthetic oil because it provides better protection and performance at high temperatures and pressures.

Q3: Can high RPM damage the engine?

A3: Yes, high RPM can potentially damage the engine if it is sustained for long periods or exceeds the engine's design limits. It can cause wear and tear on engine components, reduce engine life, and lead to costly repairs.