(14436 products available)

A highly bobbin is designed to store thread that goes around shuttle boxes. Shuttles are pivotal components of weaving machinery that move perpendicular to the warp threads. Warp threads are the threads that run vertically in a fabric. The highly bobbin plays a crucial role in ensuring sufficient thread supply for the shuttle as it moves through the loom during the weaving process, helping maintain a consistent and uninterrupted weaving operation. The following are types of highly bobbins:

Standard Highly Bobbin:

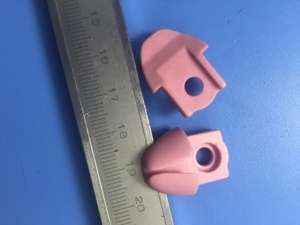

The standard highly bobbin is the traditional-style bobbin used to assemble thread in a uniform way. This type of highly bobbin is compatible with many older and modern sewing machines. It is often cylindrical and exclusively manufactured PVC or plastic material. Standard highly bobbins are typically lightweight, non-fragile, and easy to see in fabric. This makes it ideal for use in highly practical scenarios like theatre, stage, and film production.

Plastic Highly Bobbin:

Plastic highly bobbins are made from PVC or lightweight plastic. They generally last longer than those made from wood. Plastic bobbins also make it easy to tell how much thread is left, reducing the chances of running out of thread unexpectedly.

Metal Bobbins:

As the name suggests, metal bobbins are made of metal. Metal bobbins easily slide in and out of the holder. They create a snug fit for the thread.

Coreless Bobbins:

Coreless bobbins lack a central core, creating a double-sided feeding system. This allows threads to be dispensed from both sides, reducing the limits of player change and enhancing operational efficiency. Coreless highly bobbins are valuable in industries demanding high-speed production and minimal downtime, such as textile manufacturing and automation.

Specifications of highly bobbins can vary, depending on the type and model. Here are some common specifications.

Correct maintenance of highly bobbins can keep them in good condition and prolong their lifespan. Here are some maintenance tips.

Scenarios of highly bobbin

The tailoring businesses and apparel industries depend on the highly bobbins. In recent years, the DIY and arts and crafts industry has increased demand for high-bobbin stock due to their wide use in embroidery sewing machines.

There is a growing market for sewing machine bobbins from the children's garment sector. The amount of clothing produced for children requires a high-bobbin stock to satisfy output needs. The commercial sewing sector continues to be a significant market for sewing machine bobbins.

There has been an increase in demand for specialty sewing machine bobbins, such as those used for embroidery or overlock machines, indicating further market potential. Domestic sewing machine bobbins are in demand, with more people taking up sewing as a hobby or profession. Sewing machine bobbins with smart technology, such as monitoring how much thread is left on the bobbin or being able to self-thread, are in demand.

Industries that require microbiology testing or pharmaceutical-grade sterile products utilize sterile bobbins. The sterile bobbins are manufactured in a cleanroom environment and are gamma sterilized to ensure they are sterile when used for these applications.

Bobbin winder machines are used to wind thread onto bobbins for sewing machines. Several industries use bobbin winder machines. These include the textile industry, where they are used to produce threads for use in the manufacture of garments and other textile products.

India produces a significant amount of sewing thread, which is used in various industries. The country has a large textile market, which is the primary consumer of sewing thread. Other industries that use sewing thread include the leather industry, which uses thread to stitch leather goods and products, and the upholstery industry.

There are many types and choices of highly bobbin available on the market. When choosing a suitable bobbin for the inventory, buyers should keep a few key points in mind.

Apparel industry demands

First, the demands of the apparel industry for the highly bobbins should be considered. A supply of apparel products will be consistent if the demand is consistent. Therefore, it would be a sound decision to select highly bobbins that meet the demand of the apparel industry.

Connectability with other machinery

Since the highly bobbin functions as the holder of the thread, its connectability with other machinery, such as the sewing machines in the apparel industry, is crucial. It is preferable if the highly bobbin can connect with the other machines without trouble.

Highly bobbin's efficiency

When considering the highly bobbin for sewing machine selection, its efficiency should not be neglected. The productivity of the entire sewing process may be impacted if the efficiency is low.

Cost

Cost is the overriding factor in making a sourcing decision. The high bobbin's cost should be in line with its quality and efficiency. If the cost is low, it may affect the sewing process because of inefficiency and low quality. On the other hand, if the cost is high, it may not be suitable to pay for such a premium, depending on the sector's demand where the product will be used.

Small, medium and large-sized highly bobbins

When considering highly bobbins, buyers should be aware that they can be small, medium, or large. Additionally, their specific use in different types of textile products matters. For example, specific textile industries use large quantities of small-sized bobbins.

Q1: What is a bobbin in textile?

A1: In the textile industry, a bobbin is a small cylindrical object used to hold and manage thread or yarn. Bobbins are integral parts of weaving, knitting, and sewing operations.

Q2: What are the uses of bobbins?

A2: Bobbins are used to hold the following in machines and manual sewing:

Q3: How are highly bobbins made?

A3: Bobbins are made using a variety of material and techniques:

Q4: What is the difference between a bobbin and a spool?

A4: The bobbin and spool serve similar purposes but are distinct. The bobbin is a small, cylindrical object that holds the thread used in sewing machines and textile equipment. On the other hand, the spool is a bigger holder designed to hold larger quantities of threads or yarns, commonly used in sewing, crafting, and textile manufacturing.