(32 products available)

A hot sell festo pneumatic cylinder is a device used in an automated machine to apply force. It works by compressing air or other gases to move its rod. An Festo pneumatic cylinder has two main components: the body and the rod. The body is a round or tube-like container, while the rod is a long and thin metallic piece that moves in and out of the body. The following types of Festo hot-sell Pneumatic Cylinders business owners can choose from:

Standard Pneumatic Cylinders

A standard pneumatic cylinder consists of a movable piston housed in a tube-like container. It has two end caps attached to the housing. The force applied by the cylinder is at a right angle to the housing's axis. Standard cylinders from Festo can have a double-piston, dynamic cushioning, or single-piston design. The pistons have an attachment or hoop that connects and pushes objects.

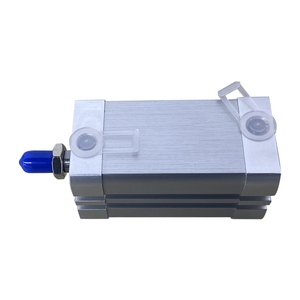

Compact Pneumatic Cylinders

These are smaller variants of standard cylinders. Compact Festo cylinders are suitable for areas where installation space is limited. They can produce a relatively high force despite their small size. Some designs even come with a shock absorber to reduce the noise level during operation.

Guided Pneumatic Cylinders

A guided pneumatic cylinder has an internal piston and an external guide. The external guide helps to stabilize and support the motion of the internal piston. This stabilizing feature makes the guided cylinder an ideal choice for moving heavy loads. It also allows the cylinder to perform accurately and reliably in diverse applications.

Tandem Pneumatic Cylinders

A tandem cylinder has two or more pistons connected in parallel or series. Doing this increases the force output and provides greater flexibility. Festo tandem cylinders combine the speed of regular cylinders with the force of double cylinders. This feature offers high flexibility and dynamic movements in applications like metal processing and glass production.

Rotary Pneumatic Actuators

These devices perform rotational movements. A rotary actuator moves its attached component in a circular motion by compressing air from a tube. The motion could be a full rotation or part of it. All rotary actuators from Festo are IP65. This means that they are dust-tight and can withstand jets of water from nozzles in any direction.

Typical specifications for a Festo standard cylinder are as follows:

An easy and efficient way to ensure long-term use and service of the pneumatic cylinder is to perform periodic maintenance.

It is recommended that the cylinder's exterior be cleaned at least once a week to remove particles and contaminants that might enter the system. Before starting any cleaning process, ensure there is no air pressure in the cylinder to avoid accidents or injury. Doing a visual inspection weekly will help the user to identify any obstacles early on or if there is any damage to the cylinder that should be taken care of immediately.

Depending on the nature of the application and the environment in which the cylinder is used, a monthly or bi-monthly lubrication process should be done on the cylinder's seals and other moving parts. Inspecting the seals on the frequently used cylinder should be done at least quarterly to avoid air leaks and friction on the moving parts. It is also a good idea to check the mounting mechanisms and the buffer as they bear the weight and pressure of the object being moved.

Pneumatic cylinders can be used in many applications in different industries. Here are some common usage scenarios for these products.

Packaging machines

Pneumatic cylinders are commonly used in packaging machines to achieve functional goals like packing, sealing, and cutting. For example, they can be used as a driving force behind the movement of packaging films or as a mechanism for the sealing and cutting of packages.

Assembly line automation

This refers to the systematic manufacturing process where parts are assembled to produce end products. In assembly line automation, these cylinders are used to achieve repetitive high-precision tasks, such as the assembly of parts, the clamping of components, and the stacking of items.

Robotics and manipulators

Pneumatic Festco cylinders are the driving forces of robots, allowing the models to reach different angles. In addition to this, they are able to hold or drop objects. Moreover, some robots are designed to mimic human movements and are called anthropoid robots. These robots use the cylinders to recreate human-like movements.

Automated sorting and conveying systems

Pneumatic cylinders are employed in automated sorting and conveying systems to achieve the distribution and transfer of items and materials. They're responsible for the linear motions that expel, position, and relay workpieces. Such actions facilitate the mounting and sorting processes, thereby contributing to the automation of production lines.

Textile and leather machinery

In the textile industry, the cylinders perform tasks like weaving, dyeing, and cutting fabrics. They are integrated into different machines to achieve diverse production goals. Similarly, in the leather craft industry, they can be used in stamping machines. The cylinder will apply pressure to emboss the leather with a distinctive pattern.

Medical devices

The function of a pneumatic cylinder in a medical instrument will vary depending on its design and purpose. However, Festos' medical cylinders are generally used to improve motion, control valves, or assist in the precise positioning of medical instruments and equipment during medical procedures. These assistive roles are made possible by the strength and accuracy of the cylinder's movement.

Automobile assembly and manufacturing

With regard to manufacturing, the devices are applicable to different stages, such as stamping, welding, and spraying. The repetitive motions are achieved with precision and high control, which make the work easier.

When selecting the best-selling Festo pneumatic cylinders for retail, it's essential to choose a diverse product range that appeals to various customers. So stocking distinct types of these products should meet different customers' requirements.

Consider stocking several sizes and strokes of Festo cylinders. The customer base will most likely comprise different industries. So some will need short-stroke cylinders, while others will require long-stroke cylinders. An assortment of these sizes and strokes will, therefore, meet various customers' needs.

Additionally, consider stocking both standard Festo cylinders and those with special features. The latter includes the clean room cylinders that can be used in a chemotherapy or culinary setting and the anti-corrosive cylinders used in coastal industries. By stocking both varieties, retailers will appeal to a broader customer base.

More importantly, offer a variety of mounting types and styles. This is especially crucial when targeting clients in the agricultural sector who use different types of farming equipment. Also, ensure to choose pneumatic cylinders compatible with popular valve brands. This is because some customers are retrofitting existing systems. Such customers will prefer cylinders that can easily fit and work with their current systems.

Finally, consider stocking cylinders with different materials and finishes. This should include aluminum, stainless steel, and non-metallic options. Different clients will have unique demands. Additionally, different material options allow customers to choose cylinders ideal for their specific applications.

Q1: What is the purpose of Festo pneumatic cylinders?

A1: Festo pneumatic cylinders are responsible for converting compressed air energy into mechanical motion. This movement can take the form of linear displacement, rotational motion, or a specific gripping action.

Q2: What types of tasks are Festo cylinders suitable for?

A2: Festo cylinders are well-suited for a range of tasks like pushing, pulling, lifting, lowering, inserting, extracting, rotating, and pivoting. They're commonly used in assembly lines, robotic arms, packaging machinery, and automated production systems.

Q3: What are the trends in the pneumatic cylinder market?

A3: The market trends include the burgeoning demand for automation within industrial settings, which has led to a sustained uptick in the requirement for pneumatic cylinders across various sectors. Notably, the adoption of Smart Cylinder Technology is reshaping the landscape; this innovative approach enables real-time data transmission from pneumatic cylinders to centralized control systems, thereby enhancing the cylinders' manageability and efficiency. Furthermore, the shift towards eco-friendly practices is compelling industries to consider energy-efficient solutions; as a result, the market is witnessing a rise in the popularity of bio-based lubricants and sealing technologies aimed at prolonging the lifespan of pneumatic cylinders.