(3135 products available)

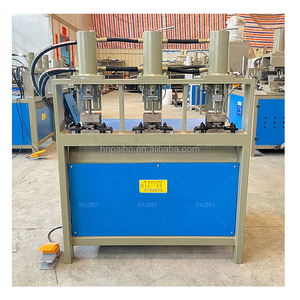

The hydraulic plastic punching machine comes in various types and models, with distinct specifications and applications. This includes table types, automatic feeding, manual operation, and electrical control models.

Tabletop hydraulic plastic punching machines

The tabletop hydraulic plastic punching machines are suitable for small-scale operations. They have compact sizes, which makes it easy to place them on workstation tables. These machines are very easy to operate. The operator controls the punching action by pressing down on the hand lever. For better precision and control, the punching dies can be exchanged and adjusted to suit specific applications.

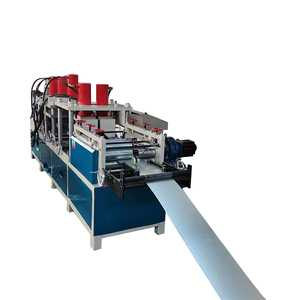

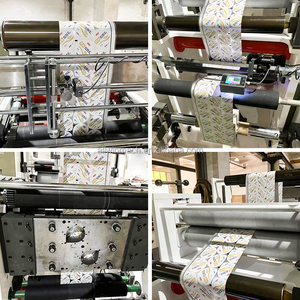

Automatic feeding hydraulic punching machines

The automatic feeding hydraulic punching machine offers a more advanced method of punching plastics. It utilizes a hydraulic system and automated feeding mechanism for constant and high-volume production. The machine has a hydraulic unit that generates a lot of force, which smoothly cuts through thick materials. It also has a precision die set for accurate and clean cuts. The automated systems can be programmed to operate continuously. This reduces operator fatigue and reduces the time between each punching operation. Businesses can use it for high-volume applications like creating holes in large sheets of plastic.

Manual hydraulic plastic punching machines

The manual hydraulic plastic punching machine is great for small businesses or workshops with limited space. This model uses hydraulic power as the main source of force. It also uses a manual lever for operation. While this machine is smaller and less powerful than the automatic models, it is very easy to set up and use. All the operator has to do is pull the manual lever to move the ram downwards and punch the material. It is suitable for businesses that don’t need to punch large volumes of plastics daily.

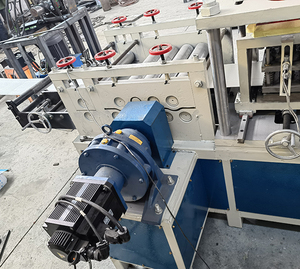

Electrically controlled hydraulic punching machines

The electrically controlled hydraulic punching machine has a very simple control system and high precision. It uses an electric motor to drive the hydraulic pump. This provides a steady and reliable supply of hydraulic fluid. The force and speed of the punching action can be easily controlled and adjusted since it is electronically regulated. This ensures uniform punching and a smooth operation. This punching machine is multipurpose. It can be used to cut plastic, rubber, leather, fiber, and other materials. It is also suitable for enterprises that handle large volumes of materials daily.

The specifications of the hydraulic plastic punch vary depending on the type, model, and brand. Below are some standard specifications for this machine.

Capacity:

The punching capacity refers to the maximum thickness of material that the machine can handle. This capacity can be adjusted to suit different kinds of materials.

Force:

The hydraulic punching force is the maximum force exerted by the punch.

It is usually measured in tons. The force of the machine determines the punching capacity.

Stroke length:

This refers to the distance moved by the punch.

The stroke length determines the depth of the punched holes.

Die sizes:

The die sizes of the punching machines will vary depending on the type and model of the machine.

They will also vary depending on the holes that are required to be drilled.

The usage scenarios for hydraulic punching machines are countless because they are versatile and can be used in different industries and applications.

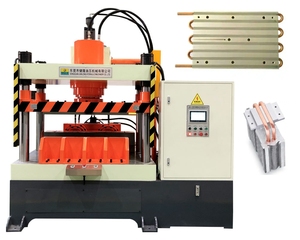

In the electrical industry, the machines are commonly used to make holes in bus bars. This includes bus bars of different materials like copper, aluminum, and stainless steel. The sizes and shapes of the holes made depend on the specific requirements. Other applications in the electrical industry include making holes in cable trays, conduit boxes, or connectors.

In the HVAC industry, the hydraulic punching machine is used to make holes in air ducts. It can be used to create holes for flanges, access points, or attachments. The machines are used to make holes in sheets of metal used for roofing in the construction industry. Using a hydraulic punching machine ensures that the roofing installation will be accurate and neat. This improves the quality of the building. With this machine, multiple holes can be made quickly, which increases production efficiency.

Manufacturers of hydraulic punching machines create specific dies so that buyers can use the machine for various applications. For instance, a round hole die will allow a user to punch out round holes of different sizes. A square hole die will be used to punch out square holes. Other specialty dies can be used to create keyways, slots, or oblong holes.

Plastic dies are used to make holes in plastic materials like PVC, PP, or polyethylene. This is very helpful in the automotive industry where the need for precise holes is required in a short space of time with minimal labor.

Both business buyers and end users stand to benefit from the following tips when selecting the best hydraulic plastic punching machines for their needs.

Assess demand and application

Determine the types of materials that the machine will be used for and the frequency of its use. Consider the specific requirements of the tasks, such as the size and thickness of the materials, as well as any particular functions or features that are needed. This will help to choose a hydraulic punching machine that has the right capacity and functionality.

Evaluate the machine's specifications

Consider the specifications of the machine, including its punching capacity, pressure, and the range of die sizes that it supports. Make sure that the machine can handle the materials and tasks that are required.

Check the machine's features

Look for features that improve performance, such as quick-change die systems, adjustable punching speeds, and automatic controls. These features can help to increase efficiency and reduce downtime.

Consider the hydraulic system's quality

The efficiency of a plastic punching machine depends on the quality of its hydraulic system. Choose machines with high-performance hydraulic pumps and cylinders that are designed for heavy-duty use.

Assess energy efficiency

Energy efficient machines reduce operating costs over time, therefore, it is important to look for models that have energy-saving features like automatic idle modes and efficient hydraulic systems.

Consider machine size and weight

The punching machine chosen should have a size and weight that is easy to handle and fit into the workspace. Ensure that it can be integrated into existing production lines without causing any major disruptions.

Examine safety features

Because of the inherent risks in using hydraulic punching machines, it is important to check for essential safety features like emergency stops and protective guards. Ensure that the machine has operator-friendly controls and ergonomics to reduce the risk of accidents.

Consider the machine's maintenance needs

Frequent machine maintenance helps to keep performance optimized and extend lifespan. Take into account the maintenance needs of different models and choose those that have easily accessible parts, straightforward maintenance procedures, and good supplier support.

Q1: What are the maintenance requirements for hydraulic punching machines?

A1:Regular maintenance is crucial to keeping the punching machine in good working condition. Users should frequently inspect the machine for any indications of wear or damage and immediately address any issues to prevent further damage. They should also make sure all fasteners are tight and clean and remove any debris or waste items from the equipment after use. Additionally, they should lubricate the moving parts of the machine to keep them running smoothly and schedule a professional servicing at least once a year.

Q2: Can hydraulic punching machines be used with materials other than plastic?

A2: Yes, some types of hydraulic punching machines can be used for materials other than plastic, including rubber, foam, and composite materials. Nonetheless, the machine may need to be fitted with specific dies or adapters for different materials. Also, the punching force, speed, and setting may need to be adjusted to suit the material's thickness and density.

Q3: Are hydraulic punching machines safe to use?

A3: Yes, hydraulic punching machines are generally safe, but users must always prioritize safety. To ensure safe use, they should be properly maintained and routinely inspected to promptly identify any safety issues. Users should also be trained on how to use the machines correctly. Additionally, the machines should be used with safety guards and emergency stop buttons.