(15675 products available)

Amazingly, an industrial cocoa grinding machine helps to transform whole cocoa beans into delicious end products like chocolate, cocoa powder, and cocoa butter. Cocoa beans are first roasted in an industrial cocoa bean grinding machine whereby the skins are cracked. This creates small pieces referred to as cocoa nibs. The nibs are then fed into a grinding machine. The grinding machines contain steel discs or blades that mill the nibs into a thick, dark liquid referred to as cocoa liquor. Heat is generated during the grinding process due to friction, and this causes cocoa butter present in the nibs to liquefy. The cocoa liquor can later be separated into cocoa powder and cocoa butter or processed into chocolate.

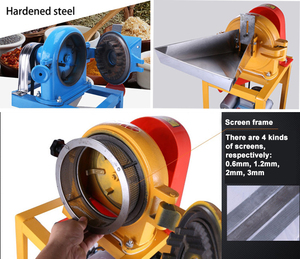

Grinding is done using different types of machines based on desired results. Three main categories include:

Some Cocoa grinding machines' key specifications include motor power, grinding capacity, and the size and weight of the machine. Buyer's can use these specifications to study how they would fit into their existing production line as well as their power requirements.

Proper maintenance is essential for optimal performance, prolonging life, and preventing breakdowns. Regular cleaning is very important. After each grinding session, all the parts of the machine should be cleaned properly. This prevents the buildup of cocoa residue and blockage of pipes. Only food-grade cleaning agents should be used. While the machine is not in use, it should be stored in dry and dust-free places. This protects it from any damage, contamination, or moisture.

During operation, the parts that move should be lubricated regularly. These include chains and bearings. The manufacturer usually provides instructions on the exact lubricant to use. Maintenance sessions should be scheduled at least once a year. During this time, the machine's critical components, such as motors, belts, bearings, and grinding parts, should be inspected. Any worn out or damaged parts should be replaced immediately. Belts should be adjusted to ensure they are not too tight or loose. Because these machines have complex electrical components, only certified electricians should attend to them.

Industrial cocoa grinders are staple pieces of equipment in large-scale chocolate production facilities, which may be both commercial and industrial. However, they are also invaluable assets to smaller-scale productions of certain cacao products.

Grinding is the main purpose of these huge machines, and it isn't limited to what cacao beans can produce. Other nuts are also ground with them to extract their oil and make that particular blended cocoa-nut butter.

In general chocolate-making companies, these significant industrial grinders are the beginning of the process of creating the raw, essential chocolate paste, fat, or liquor from which everything else can be made. This may include chocolate milk, pure dark chocolate, and even white chocolate, which does not contain any cocoa content but is comprised of cocoa butter mixed with other dairy and sugary ingredients to produce a sweet product desired by many customers.

The grinder machine works efficiently to break the cocoa beans down into a fine paste, which is the first step in excess chocolate production. Some grinders offer unprecedented versatility in that they can very quickly and easily change the grind size all within a few minutes. This option is critical for businesses who want to produce different cocoa-based products or change the formulas and flavors of their products on demand.

While large-scale commercial chocolate-producing facilities utilize industrial cocoa grinding machines to process significant amounts of cocoa into liquid chocolate flills, other products, such as chapsticks and body butters, can be made using the same fundamental fermented and ground cacao beans. These may be combined with different flavors, such as coffee, mint, or vanilla, to create interesting, tasty, and peculiar products that could be successful on a specific target market's shelves.

It may be noted that smaller-scale companies with not-so-industrial-strength cocoa grinders may also use other grinders more suited to lower-scaled production — the same goes for those not-so-industrial-sized cocoa beans. In such cases, smaller-scale, more straightforward machines, such as mortar grinders or melangers, are perfect.

While selecting an appropriate grinding machine for cocoa beans, buyers need to keep the following factors in mind.

Production Capacity

The typical weekly and monthly produced amounts must first be considered in order to select the right cocoa grinding machine. The consistent production rate must match the machine's capacity in order to meet demand.

Quality of Ground Cocoa

While different types of cocoa powder have varying particle sizes, consumers will always prefer a specific flavor and aroma. The grinder selected will have an impact on these characteristics. Machines that have better control over particle size and flavor retention will ensure that the final product is of high quality.

Cost of the Grinder

When calculating costs, remember to factor in operating and maintenance expenses in addition to the upfront purchase price. A low-cost machine could have high energy usage and regular repair needs, which could increase total expenses.

Technological Features

Some advanced grinders have automated processes, which could increase energy efficiency. Functions like automated cleaning and temperature control during grinding can help reduce waste and improve overall productivity.

Supplier’s Reputation

When considering a new cocoa powder machine, be sure to choose a supplier with a proven track record. Check customer reviews to see if those buying the same machines have experienced issues or not. A reputable supplier will have better technical support and will ensure spares are available when needed.

Noise Level

Sound measurements from grinders are typically expressed in decibels and should be used to determine which machine creates the least amount of noise. While all grinders will create some noise, machines with smooth, well-balanced rotors and efficient motors will run more quietly.

Q1: How does an industrial cocoa powder grinding machine function?

A1: The grinding process includes three stages: pre-grinding, fine grinding, and emulsifying. The nibs are coarsely crushed by a rough grinder in the first stage. The cocoa nibs are further crushed by a fine grinder into a thick liquid in the second stage. The oil content of the cocoa paste is extracted by an emulsifier, which also separates the fat and powder.

Q2: What are the types of industrial cocoa powder grinding machines?

A2: There are four cocoa powder-making machines: the cocoa nibs grinding machine, the cocoa butter star separator, the cocoa butter press machine, and the cocoa powder milling machine. These machines are often used as a complete set to produce cocoa powder from cocoa beans.

Q3: What are the three-step processes of grinding cocoa powder?

A3: The three steps of grinding cocoa powder are pre-grinding, fine grinding, and emulsifying. First, the nibs are coarsely crushed by a rough grinder. Then, the cocoa nibs are further crushed by a fine grinder into a thick liquid. Finally, an emulsifier extracts the oil content of the cocoa paste and separates the fat and powder.

Q4: What are the advantages of an industrial cocoa grinding machine?

A4: An industrial cocoa grinding machine provides large-scale production of cocoa products. It is made of stainless steel for long-lasting use. The machine is multifunctional. It can make cocoa butter, cocoa powder, or cocoa mass, sharing the same grinding core with other food materials.