(164 products available)

Iron-casting ductile grill grates have different types that suit different needs. Each one has other features that affect their performance and durability.

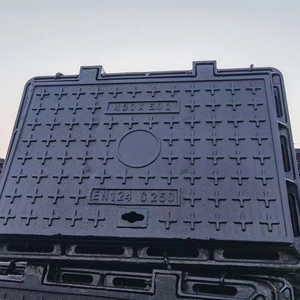

Duplex and symmetric iron-casting ductile grill grates have massive designs with double and symmetric structural support grids, respectively. These grates are suited for heavy-load applications in the industry. The duplex grates made from iron casting ductile offer excellent load-bearing capacity. In contrast, the symmetric grates focus on uniform weight distribution across the surface. Ductile iron's flexibility and strength allow for long-lasting, durable grates in challenging environments. Symmetric grates are employed in conditions requiring equal weight distribution, while duplex grates find application in areas with heavy and uneven loads, demonstrating their robust performance in industrial contexts.

The slot type ikw grates allow for the free flow of liquids and prevent the accumulation of debris. The well-spaced slots in these grates make them ideal for use in areas where fluid drainage is essential, such as drainage ditches or wastewater treatment facilities. Constructed from ductile iron, these grates offer both flexibility and high tensile strength, making them resistant to wear and tear in harsh environments. Furthermore, their lightweight design facilitates easy installation and maintenance compared to other heavier grate types.

Square opening grates are designed to provide a solid walking surface while allowing the passage of water and small debris. The square openings prevent clogging while offering structural support. These grates are commonly used in pedestrian areas, parks, and sidewalks where both load-bearing capacity and drainage are essential.

The type of grill grate, which provides a higher level of resistance to the loads that are likely to be exerted on it, is made to handle the demands commonly found in commercial and industrial settings. These protectors are generally placed in areas with considerable traffic or weight, such as truck drives, industrial floors, or loading docks. Their strength and long life come from utilizing ductile iron, which supports greater weights without twisting or breaking. Hardly ever, these heavy-duty grates also have backing bars or reinforcing ribs, which increase their load-carrying capacity even more.

The function of a plain type grate is to construct a level platform that supports traffic while restricting the passage of big items or solids. Pedestrian walkways, access roads, and light vehicle roads are some areas where these grates are needed to sustain low loads and provide backing for plates and platforms to walk on. Because there are no openings for water to pass through, the upper surface is smoother, which prohibits vehicular crush washing and makes pedestrian mobility more comfortable.

Furthermore, compared to other kinds, they are simpler to set up and maintain. The two features of being easy to care for and durable make these ideal for low-duty applications.

Many materials and their long-lasting nature are important in making iron casting ductile grill grates. Understanding clearly the materials used and how durable they are will help buyers select the best products.

Grates made from ductile cast iron are not naturally resistant to corrosion. However, their endurance can be significantly improved through protective coatings like galvanized layers, powder coats, or epoxy. Such methods act as a barrier against moisture, harsh chemicals, and the wearing influence of weather elements, extending the lifespan of the grates.

Ductile iron's high level of impact resistance means that grates can absorb shocks without being deformed. This capability is crucial in settings where heavy vehicles or equipment frequently move about. Additionally, abrasion resistance ensures that the grates do not wear out quickly due to constant contact with different materials. Consequently, these features ensure a long-lasting product, even under tough working conditions, which cuts down on the need for frequent replacements.

Thermal resistance is a chief property of grates in barbeque grills and fireplaces. Ductile iron endures extreme temperatures without warping or cracking, which is critical for grilling and casting fires. The material's capacity to maintain heat evenly also promotes better cooking results. To achieve even higher thermal resistance, coatings can be applied to the grill grates to inhibit oxidation and potential heat-induced corrosion.

Among the hardiest metals is ductile iron. It is strong enough to carry heavy weights without breaking or twisting. That is why these types of grills are made for roads, docks, and industries and can tolerate extreme forces. The material equally has high toughness. Thus, it will not break even if subjected to extreme bending or twisting. This makes them very suitable for dynamic environments where lots of vibrations are experienced.

The above grill grates have many uses in different industries. Thus, understanding the commercial uses of these grill grates will guide buyers toward the right applications and industries.

In wastewater treatment plants, grill grates for wastewater are used as protective elements to prevent large objects from damaging pumps and other sensitive equipment. They are vital in primary treatment systems and need to be durable enough to withstand constant exposure to water, chemicals, and heavy objects. Because of their corrosion resistance, the grates are well-suited for demanding waste environments.

In castings and foundries, the grill grates serve as cooling and support bases for molten metal casts. Thus, they absorb intense heat and provide solid footing so the molten metal does not twist or shatter. Ductile iron's ability to withstand extreme temperatures without deforming makes it essential in all foundry processes, including pouring.

The mining industry is one sector where grill grates have a huge opening and closing demand. Mining debris can be heavy and sharp; hence, heavy-duty grill grates are ideal in this sector. They are used in smelting furnaces, loading zones, and mining equipment to prevent large objects from contaminating fluids or damaging machinery. These robust structures are thus necessary for sustaining hazardous underground and surface mining environments.

Agricultural grates are employed to protect irrigation channels and drainage systems from large debris, preventing clogs and ensuring efficient water management. They are used for livestock enclosures, feed storage buildings, and agricultural equipment workshops. They are needed to endure outdoor conditions, including wet and dry terrains and vehicle traffic within farms.

In transportation systems, grill grates serve as functional elements in roadways, bridges, and railway tracks. Their primary function is to support traffic load while facilitating water drainage and preventing soil erosion. Thus, bridge grates are made to withstand vehicle and pedestrian weight, offering safety and durability in transportation networks.

To select the best grill grates, buyers must consider various key factors. The following sections will highlight the important considerations for choosing the iron-casting ductile grill grates.

In terms of durability, ductile cast iron is very strong and wears and tears resistant. This is what makes it suitable for harsh and demanding conditions. Look for grill grates that have extra protections, like coatings that prevent rusting or corroding. Also, ensure they are thick enough to resist bending or warping under extreme heats or weights.

Decide the maximum load a cast iron grill will experience in its application. For instance, structures like roadways and industrial workspaces should have high work support capability. Choose the strength of the material that goes hand in hand with the required load-bearing capacity. The thicker and heavier the grate is, the stronger it is.

Since they are made for the outdoors, they will be exposed to different elements, including water, chemicals, and weather. Setting the right level of corrosion resistance will ensure the grates last for many years.

Compared to other grill grates, cast iron cookware can be demanding in maintenance. Some grill grates may have coatings that make them easier to clean. Others may require regular maintenance to ensure they do not rust or corrode.

Highly resistant-grill grates will not deform or warp, especially under extreme heats. At the same time, they should equally distribute the heat to guarantee uniform cooking. This is ideal for making sure one all-around experiences the same temperature in every area of the grate.

They have high tensile strength and resistance to deformation. They can tolerate large weights and resist bending or warping. This makes them ideal for industrial areas.

The corrosive nature of water, chemicals, and weather is reduced. Thus, the grates last longer and require less maintenance. Outdoor and marine environments equally benefit from this.

Coatings such as galvanized layers protect the grates from corrosion, chemical exposure, and wear and tear. They act as a protective barrier that extends the life of the grates.

They are not eco-friendly, but they have long-lasting coatings. This means there is less need for replacement. Moreover, they go through fewer emissions.

They are highly resistant to thermal shock. They will not warp or crack when exposed to rapid temperature changes. Proper maintenance and high-quality coatings enhance this resistance.