(3759 products available)

A kiln burner is an important component of a rotary kiln that has various designs to meet different industry needs and optimize fuel efficiency. This section will discuss some of the most common types of kiln burners.

The main parameters to consider when buying are the number and types of kiln burners efficient. Models all have different specifications because they suit distinct kiln types.

Regular care keeps the burner working fine and reduces breakdowns. Some general tips for long-term use include:

Cement industry:

Cement plants are the main application area of refractory cement kiln burners. The refractory cement kiln burner can adapt to the entire process of cement production and the characteristics of different fuels. By improving the heat value of the fuel, it maximizes the calorific value utilization.

Industrial metallurgy:

Refractory cement kiln burners can be applied to achieve smelting in the metallurgical industry. For example, in iron and steel metallurgy, they can be used to smelt iron and steel by using various kinds of fuel, including heavy oil, diesel oil, natural gas, and others. The quality of the product will not be affected by the even and stable combustion it provides.

In non-ferrous metallurgy, refractory cement rotary kiln burners can also be used in various non-ferrous metal smelting processes. For example, aluminum, copper, lead, zinc, and other metals burning setups can be optimized and adjusted by rotary kiln burners. Thus, enhancing the extraction and utilization of non-ferrous metals.

Glass industry:

In the glass industry, refractory cement kiln burners are responsible for the melting of raw materials. At the same time, they need to ensure uniform heat distribution, which is essential for obtaining high-performance and high-quality glass products.

Mineral processing:

The processing of minerals, such as the treatment of ores like copper, nickel, and others, requires a lot of heat. This is because chemical reactions or changes must take place at high temperatures. Such conditions must be ensured by utilizing mineral processing rotary kiln burners.

Sanitary ware industry:

Sanitary ware facilities play a crucial role in the intelligent life of the city. The sanitary ware industry needs high temperature and constant temperature throughout the firing process to ensure ware's stability and durability. Precise control of temperature is required throughout the firing process in the sanitary ware industry to ensure the product's stability and durability. Rotary kiln burners for sanitary ware can provide a steady and even high temperature, thus meeting the sanitary ware industry's quality and requirements.

Production Requirement:

The primary purpose of a kiln is to produce a specific amount of material over a set time. When determining what type of kiln is needed, it is critical to assess the quantity that is required.

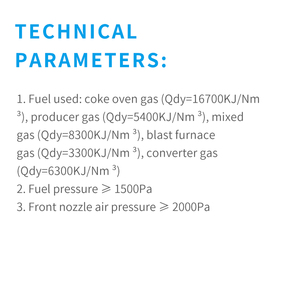

Fuel Source:

Kiln burners require a fuel source to operate. Factors like availability and budget will play a role in determining what fuel is used. Natural gas is abundant and provides a cost-effective option. Coal is also a widely used fuel but requires more manual processes to operate. Electricity is an alternative but provides a lower output. The primary fuel options are discussed further in the main article.

Temperature Requirement:

Each material has a specific temperature at which it must be heated to achieve the desired result. The operating temperature of the kiln burner should be high enough to meet these requirements. Materials like ceramics and cement require operating temperatures of over 1,200°C.

Budget:

The amount of money that is available will ultimately determine which kiln is chosen. The budget must include the cost of installation and the operating expense. More energy-efficient models usually have a higher purchase price but could save considerable money in the long run.

Environmental Impact:

How the kiln's carbon footprint is measured will also determine the kind of burner needed. Carbon emissions have a financial impact on businesses. Reducing emissions will require selecting a kiln with an efficient burner as well as a fuel-efficient design.

Firing Time:

The time allowed for the firing process will also influence the choice of kiln. A quick turnaround will require a high-capacity burner. If there's enough time for the process, a more economical option that uses less energy could be chosen.

Q1 What are the latest trends in kiln burners?

A1 Trends such as waste heat recovery, advanced materials, air-sealed positive-displacement rotary feeders, selective catalytic reduction to minimize NOx emissions, automated control systems, high-efficiency secondary air systems and low-NOx kiln burners are becoming popular.

Q2 What are some ways to improve the efficiency of a kiln burner?

A2 Use waste heat recovery systems, centralize insulation, optimize the combustion process, apply high-efficiency kiln burners, properly maintain the kiln burner, automate the control system and optimize fuel selection.

Q3 What are the benefits of using low-NOx kiln burners?

A3 Low-NOx kiln burners help to reduce nitrogen oxide emissions, improve air quality, protect the environment, comply with regulatory requirements, enhance the sustainability of industrial processes and promote responsible business practices.

Q4 What are the components of a kiln burner?

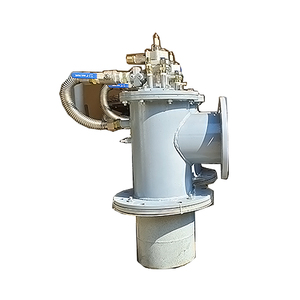

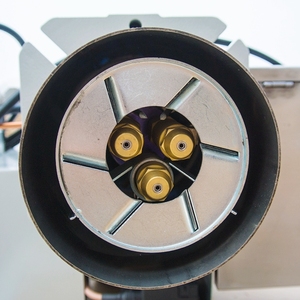

A4 The main components of a kiln burner include the body, primary air inlet, fuel nozzle, combustion chamber, secondary air inlet, throat, nozzle disc, fly ash discharge, rotary drum, sealer, end cap and furnace lid.

Q5 What are the different types of kiln burners?

A5 The different types of kiln burners include the oil and gas mix burner, pre-mixed gas burner, direct-firing gas burner and pulverized coal gastrifier. Each kind has its own characteristics and applicable fields.