Types of Laser Cutting Machines for Oman

The laser cutting machine is used for multiple cutting applications in Oman, and some of the popular types are listed below.

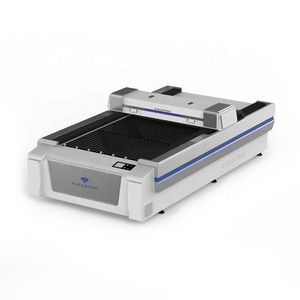

CO2 Laser Cutting Machine

These machines use an energized gas mixture to produce lasers. The CO2 machine works well with non-metal materials such as acrylic, wood, glass, and fabric. The CO2 laser engraving machines usually have large working areas, which makes them ideal for industrial cutting.

Fiber Laser Cutting Machine

This machine uses a fiber optic wire to generate the laser. A fiber laser cutting machine is commonly used for metal cutting. It provides high precision and efficiency, especially for thin metal sheets. Fiber lasers are suitable for materials such as aluminum, brass, and stainless steel.

Crystal Laser Cutting Machine

Crystal laser machines use a process known as laser engraving to result in a smooth and polished cut edge. Crystal laser machines have high precision and efficiency when used on crystal glass products. This makes them ideal when they are used in producing trophies, awards, and decorative items.

Hybrid Laser Cutting Machine

These machines combine the benefits of CO2 and fiber lasers. The hybrid machines can cut both non-metal and metal materials with efficiency and precision. This versatility makes them a suitable option for businesses with diverse cutting requirements.

Industrial Applications of Laser Cutting Machine Price for Oman

Laser cutting machines are employed in many industries in Oman, including metalworking, signage, automotive, and electronics. The high precision and efficiency of laser cutting make it an ideal choice for complicated designs and intricate patterns.

Metal Cutting and Fabrication

Metalworking industries use fiber laser machines for cutting metals like stainless steel, aluminum, and brass. Laser cutting provides precise edges and reduces wastage. This makes it an ideal process for high-precision tasks such as aerospace components, automotive parts, and machinery.

Moreover, laser cutting offers a clean cut that requires minimum post-processing. This leads to improved productivity and shortened turnaround times.

Signage and Display Manufacturing

Companies that manufacture signage and displays in Oman use laser cutting machines to cut acrylic, wood, and metal materials. Laser cutting machines have an exceptional ability to create intricate designs, logos, and custom signage that meet specific aesthetic requirements.

This is done without the need for costly or complicated dyes. This makes it a cost-efficient method, especially for custom signage or small production runs. In addition, the precision ensures that the signs have sharp edges and a professional appearance.

Sheet Metal Processing

Sheet metal industries in Oman have also adopted laser cutting. They use it to cut metal sheets into various shapes and sizes. Laser cutting offers precision and speed. It helps the industries create parts for HVAC systems, enclosures, and automotive body components. This technology also eliminates the need for drilling or punching, saving both time and resources.

Jewelry and Custom Products

Oman's jewelry industry uses laser cutting machines to create intricate designs in metals such as gold, silver, and platinum. The precision of laser cutting allows for detailed work. This results in finely crafted pieces that satisfy customer demands.

Also, laser cutting is used to create custom products ranging from trophies to personalized gifts. This enables quick turnaround times while maintaining high-quality standards.

Electronic Components

In the electronics industry, laser cutting machines are employed to create circuit boards and other components. It is used to achieve high levels of precision required for this complex process. As a result, this leads to improved functionality and performance in electronic devices. Additionally, laser cutting minimizes wastage. This is because it only uses the required amount of materials.

Product Specifications and Features of Laser Cutting Machine Price for Oman

The specifications and features of laser cutting machines vary widely depending on the type of laser used and the materials being cut. Oman laser cutting machines have multiple features that make them stand out.

Technical Specs

- Laser Type:CO2, fiber, and crystal.

- Laser Power:Ranges from 50W for thin materials to 2000W for heavy industrial use.

- Cutting Speed:Normal cutting speeds range from 1 to 60 mm/min.

- Cutting Area:Depends on the model, but can be up to 3000 x 1500 mm.

- Materials: Various materials like acrylic, wood, metal, and glass.

How to Install

- Choosing a Workspace: Make sure the area where the laser cutting machine will be is large enough and free of clutter. The workspace should be large enough for the machine and set up for collecting fumes.

- Setting Up the Machine: Place the machine where it will stay. Level it so it works right. Read the guide to learn how to put it together.

- Linking the Parts: Attach the parts that need connection, like the power cord and any other cords.

- Software Setup: Load the needed software on the computer so the machine can be controlled.

- Testing the Machine: Run a simple test to check that the machine is working in the right way.

How to Use

- Prepare the Material: Pick and clean the material to be cut and make sure it is free from dust and other contaminants.

- Upload the Design: Install the software needed for the machine and use it to upload the design file that needs cutting.

- Set the Machine: Choose the right laser settings based on the material type. Adjust the focus and height of the laser as needed for the material.

- Begin Cutting: Press the "Start" button to make the laser start cutting the material.

- Monitor the Process: Very closely watch the cutting process to be ready to stop it in case of problems.

Maintenance and Repair

- Clean the Lens: Use a safe solution or wipes daily to keep dust off the lens inside.

- Look Over the Machine: Check for worn parts like belts or gears weekly.

- Change Filters: Switch out air filters every few months or when dirty.

- Oil Rails: Apply special machine oil to rails every month for smooth movement.

- Follow the Manual: Read the machine's manual for more tips on maintenance and repairs.

Quality and Safety Considerations of Laser Cutting Machine Price for Oman

There is a need to ensure the quality and safety of laser cutting machines in Oman. This will enable them to function properly and ensure that they do not pose risks to users and this is done through the consideration of multiple factors listed below.

Laser Cutting Machine Quality Checks

- Laser Alignment:Proper laser alignment ensures precision cuts. One can do this by using measurement tools to check if the laser is aimed right.

- Mirror Quality:Dirty or damaged mirrors waste power and lower cut quality. Always check for spots or cracks and change mirrors often.

- Finishing:Look at the cut edges to see if they are rough. Adjust settings to reduce burning or debris for smooth ends.

- Control Software:Outdated software causes errors during cutting. Update programs regularly to ensure accurate operations.

- Material Testing:Run test cuts on scraps to set the right speed and power before starting on the main material.

Laser Cutting Machine Safety Considerations

- Safety Goggles:Wear special safety goggles for laser cutting. They protect eyes from harmful laser beams.

- Emergency Stop:Know where the emergency stop switch is on the machine. It instantly stops cutting if something goes wrong.

- Ventilation:Ensure good air flow in the space. Proper ventilation keeps smoke and gases from cutting lasers.

- Laser Shielding:Always use laser shields on cutting areas. They block accidental laser exposure to keep users safe.

- Emergency Procedures:Learn emergency plans in case of fires or other serious troubles.

- Regular Checkups:Have machines checked often by experts to fix issues and lower risks.

Fixes for Common Problems

- Alignment Issues:If cuts are not straight, check mirrors and lenses.

- Power Loss:If laser is weak, clean lens or change settings based on material.

- Smoke Buildup:Clear smoke paths and use exhaust fans during cutting.

- Software Errors:Be sure to update all programs and drivers.

Merchant and Buyer Suggestions for Laser Cutting Machine Price for Oman

When selecting a laser cutting machine, merchants and buyers should consider the operating costs, parts used to make the machine, and the technology used in it.

Merchants should keep the following in mind.

- Machine Durability:Choose machines made to handle a lot of work without breaking down.

- Upkeep Costs:Consider how much it will cost to fix and maintain the machine over time.

- Cutting Range:The cutting area should be big enough to handle various jobs.

- Laser Type:Get CO2 or fiber lasers depending on what customers will be using them for.

- Support:Pick brands that are known for quickly helping with issues or questions.

Buyers should do the following.

- Factory Checks:Ask for proof that the factory makes machines to meet set quality standards.

- Bulk Orders:When ordering in bulk, buyers should seek special deals to lower costs.

- Custom Requests:Let the supplier know if there are any custom orders so they can be ready.

- Costs:Do the buyer's research to find the real costs and make sure they are fair.

- Review Results:Look at past buyer reviews to see what jobs the machine best handles.

Q&A

Q1. Can a laser cutting machine be used to cut metals?

A1. Yes, there are laser cutting machines that can cut metals, especially fiber lasers. Fiber lasers do a great job of cutting thin metal sheets precisely.

Q2. Which materials are best for cutting with CO2 and crystal lasers?

A2. CO2 and crystal lasers work best for non-metal materials like acrylic, wood, glass, and fabric. These lasers can easily cut intricate designs into these softer materials.

Q3. Does the size of a laser cutting machine matter?

A3. Yes, the size does matter. Larger machines can handle bigger materials and projects but take up more space and may cost more. Smaller machines are better for compact workspaces.

Q4. How can one optimize cutting speed and precision on a cutting machine?

A4. Testing on scrap material first is a great way to find the best settings. Adjusting the laser power and speed for each material helps achieve clean cuts with precision.

Q5. Are laser cutting machines eco-friendly?

A5. Laser cutting machines are kinder to the Earth than many older machines. They use less energy, create less waste material, and cut things more accurately.