(359 products available)

Mobile cover laser cutting machine come in various types, each designed for specific cutting tasks. Here are the most common types:

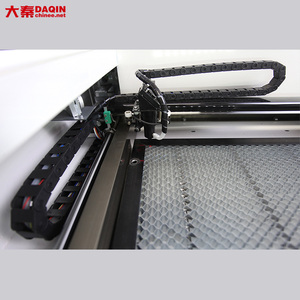

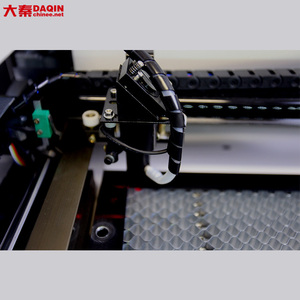

CO2 Laser Cutting Machines

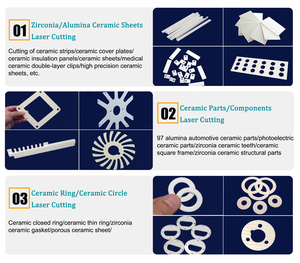

CO2 lasers are ideal for cutting and engraving a wide range of materials, including acrylic, wood, and fabric. These lasers are highly effective for mobile covers made from non-metallic materials. Known for their precision and efficiency, CO2 laser cutting machines are widely utilized in industries where intricate designs are essential.

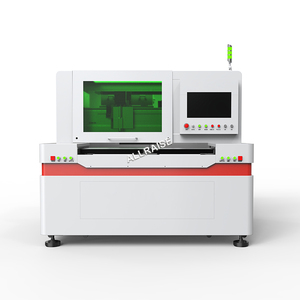

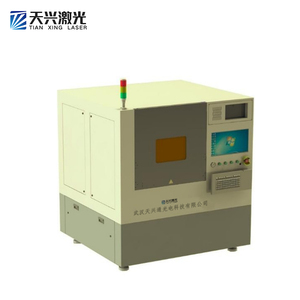

Fiber Laser Cutting Machines

Fiber lasers are mainly used for metal cutting, such as stainless steel and aluminum. The machine's high energy density allows for deep and precise cuts with minimal heat distortion. This technology is rapidly gaining popularity in the mobile cover industry, especially for manufacturers dealing with metal covers or hybrid models incorporating metal elements.

Nd:YAG Lasers

Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) lasers are best for applications requiring occasional use. These machines are particularly beneficial for businesses just starting or those needing a reliable source for occasional high-precision tasks such as cutting metal mobile covers or engraving designs.

UV Laser Cutting Machines

UV laser machines provide a unique advantage by focusing on energy at a specific point. This advantage makes UV lasers suitable for cutting delicate materials that might burn or warp under the heat of other laser types. They are commonly used for mobile covers made from optical plastics, glass, and other heat-sensitive materials.

Hybrid Laser Cutting Machines

Hybrid laser cutting machines combine CO2 and fiber lasers in a single system. This flexibility allows manufacturers to handle diverse material requirements without investing in multiple machines. Hybrid systems are especially advantageous for businesses with mobile cover designs requiring both metal and non-metal cutting. The dual functionality enhances operational efficiency by eliminating the need for separate cutting equipment.

Mobile cover laser cutting machines play a significant role in various manufacturing processes. Here are some key industrial applications:

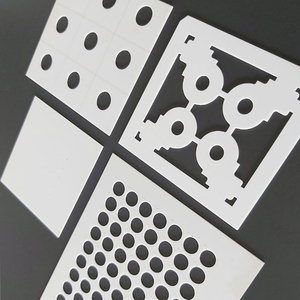

Custom Mobile Cover Fabrication

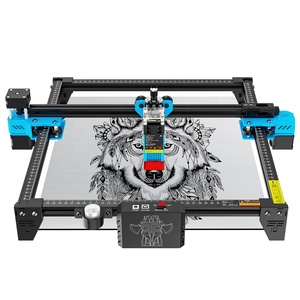

In mobile cover manufacturing, laser cutting machines are used to create custom designs and shapes. The precision and speed of laser cutting allow for intricate designs that enhance the aesthetics and functionality of mobile covers. Whether using acrylic, wood, or metal, laser cutting provides clean edges and accurate cuts. This leads to minimal material waste and high production efficiency.

Material Testing and Prototyping

Laser cutting is essential in material testing and prototyping. With its capacity to cut virtually any material by creating precise and accurate prototypes of mobile cover designs, laser cutting enables manufacturers to test different materials and designs. This helps identify the best options before large-scale production begins. Moreover, by extending the prototyping phase, companies can fine-tune their designs to better meet consumer demands, ultimately saving time and costs in the long run.

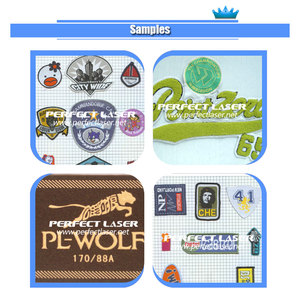

Engraving and Personalization

Laser engraving adds value to mobile covers by allowing for personalized designs, logos, and text. This feature is especially popular in retail and bulk manufacturing, where customization can set products apart in a saturated market. Advanced laser engraving machines produce detailed and intricate designs that improve the aesthetic appeal of the covers. This makes them more desirable to consumers.

Quality Control and Inspection

Laser cutting machines can also be used for quality control and precision inspection in mobile cover manufacturing. By employing laser technology to detect discrepancies in shape or size, manufacturers ensure that only covers meeting the highest quality standards proceed to the next stage of production. This application of lasers not only enhances product quality but also minimizes defects and reduces wastage.

Automotive and Aerospace Applications

Laser cutting machines are employed in the automotive and aerospace industries for cutting components used in mobile devices integrated within these environments. The machines' ability to handle thin yet strong materials makes them ideal for creating lightweight yet durable mobile covers for aerospace applications. They can also ensure that automotive parts meet precise machining requirements.

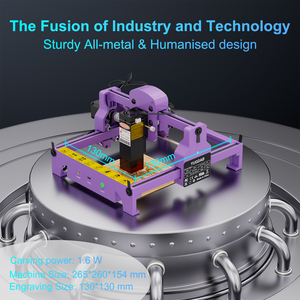

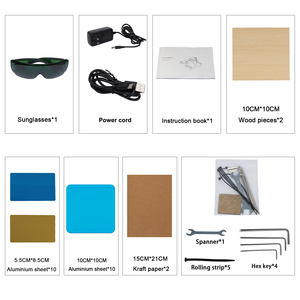

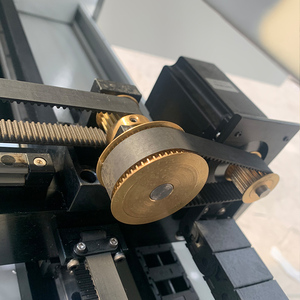

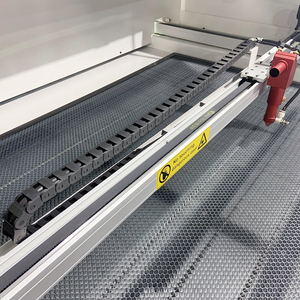

Mobile cover laser cutting machines come with various specifications and features that determine their performance and capabilities. Here are some key specifications and features to consider:

Proper installation and setup guarantee optimal performance for mobile cover laser cutting machines. Follow these steps to install and set up the devices:

Frequent maintenance and repair of mobile cover laser cutting machines increase their longevity and efficiency. Here are some tips for maintaining and repairing them:

Ensuring quality and safety is paramount. In this section, the focus will mainly be on the article's key points:

Quality Considerations

The major quality needs of operating a laser cutting machine include paying attention to factors such as the laser's precision, material compatibility, and how well it performs under exceptional conditions. High accuracy guarantees detailed cuts, improving mobile cover functionality and aesthetic appeal. Integration of quality control measures such as regular maintenance and staff training ensures consistency in production. Employ machines with quality certifications like ISO to reduce risks and follow industry standards.

Material Quality

Use only high-quality materials for mobile cover laser cutting machines. Assess the material quality, as inferior material leads to inefficient laser cuts and low product quality. Test new materials before large-scale use to determine their compatibility with the machine and laser settings.

Safety Considerations

When working with a standard mobile cover laser cutting machine, there are always some safety issues, including dealing with high-power lasers, flammable materials, and intense heat. Some of these machines commonly come with safety features such as emergency stops and enclosing mechanisms to reduce accidents. All operators accordingly should put on protective eyewear that guards against laser exposure. Furthermore, manufacturers' installation of proper ventilation systems aids in the alleviation of hazardous fumes generated during cutting.

Preventive Measures

Some methods for injury prevention include safety training for personnel and regular risk assessments. Educating laser cutting machine operators on possible hazards and proper usage practices encourages a safe working environment. This aids in the reduction of exposure to laser beams, moving parts, and machine malfunctions.

A1: It is a machine that cuts or engraves designs on covers using a focused laser beam for precision.

A2: Laser cutters can cut acrylic, wood, and metal. Fiber lasers are ideal for cutting metal, while co2 lasers work well for non-metallic materials.

A3: Maintenance entails cleaning lenses, aligning lasers, and regularly inspecting parts. Emergency repairs should be performed cautiously while wearing protective gear.

A4: It comprises the installation of lasers and software, the placement of materials, and the observance of safety measures.

A5: Maintain closed the machine's entrances during the cutting process, monitor it during operation, wear safety goggles, and perform routine maintenance.