Understanding Motor RPM 20

In the realm of electric motors, the term motor RPM 20 refers to a specific rotational speed of 20 revolutions per minute. This characteristic is critical for applications requiring slow, controlled movement. Understanding what motor RPM 20 entails helps users make informed decisions when selecting a motor for various industries, including manufacturing, automation, and robotics.

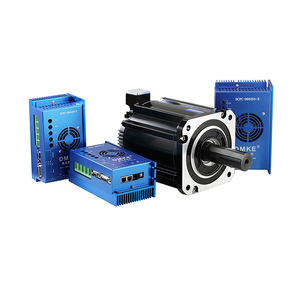

Types of Motors Operating at Motor RPM 20

Several types of motors can achieve a motor RPM 20 speed, each designed for different applications and needs. These include:

- DC Motors: Commonly used in electric vehicles and toys, DC motors can easily be controlled to maintain a low RPM of 20.

- Stepper Motors: Ideal for precision applications, stepper motors can provide accurate control at low speeds, including 20 RPM.

- AC Induction Motors: These motors can operate efficiently at various speeds, including 20 RPM, suitable for industrial applications.

- Gear Motors: By adding a gearbox, standard motors can be modified to achieve lower RPMs while maintaining torque.

Applications of Motor RPM 20

The motor RPM 20 speed is beneficial in multiple scenarios where precision and control are paramount. Below are some notable applications:

- Conveyor Systems: Used in manufacturing, motor RPM 20 helps ensure a steady and controlled flow of materials.

- Robotics: Precision robotics often requires motors that can operate at low speeds for delicate movements.

- Textile Machinery: In the textile industry, low-speed motors are essential for applications like fabric winding and cutting.

- Water Pumps: Certain water pump applications require low RPMs to promote efficient flow rates without agitation.

Features and Advantages of Motor RPM 20

Choosing a motor with a motor RPM 20 specification can offer numerous features and advantages, including:

- Enhanced Control: The low speed allows for greater control in applications requiring precise movements.

- Energy Efficiency: Motors operating at lower RPMs tend to consume less energy, resulting in reduced operational costs.

- Prolonged Motor Life: Slower speeds can lead to less wear and tear on motor components, enhancing overall durability.

- Versatility: These motors can be used in a wide range of applications, from simple household tools to complex industrial machinery.