(1107 products available)

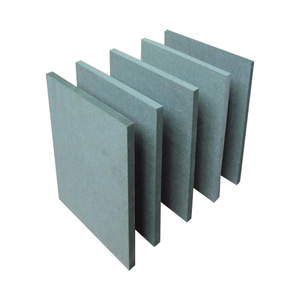

Plain medium density fiberboard (MDF) is an engineered wood product made from wood fibers, wax, and resin, which are compressed into dense board. This board has a smooth and uniform surface, making it suitable for various applications. Medium density fiberboard is popular among architects and interior designers because it is very versatile and cost-effective. This board can be used in many applications, such as furniture, cabinetry, and decorative paneling.

The types of plain medium density fiberboards are as follows:

Regular MDF

Regular MDF is also known as plain medium density fiberboard. It is the most commonly used MDF. It is made from wood fibers, wax, and resin. This makes it a smooth and dense board. Regular MDF is popular because it is budget-friendly. It is used in many applications, such as making furniture, cabinets, and drawers. It is also used in interior designs, like making custom shelves and dressers.

Moisture-Resistant MDF

This moisture-resistant MDF is also known as waterproof MDF board. It is suitable for areas with high humidity, such as kitchens and bathrooms. The board is treated with special chemicals during manufacturing. This prevents water from penetrating the surface and keeps it from swelling or warping. Waterproof MDF is popular among interior designers because it is easy to work with, and it provides a smooth finish. It can be used to make vanities, and built-in storage units.

Fire-Retardant MDF

Fire-retardant MDF is specifically designed to improve its fire resistance. During manufacturing, fire-retardant chemicals are added. This helps to reduce the spread of fire and increase the board's safety. Fire-retardant MDF is commonly used in commercial spaces that require fire safety regulations. For instance, it is used in making fire-rated doors and wall coverings.

Ultrahigh Density MDF

This ultrahigh-density MDF is also known as High-Performance MDF. It is manufactured to achieve very high density. The boards have high weight and thickness. Ultrahigh-density MDF boards have high strength and durability. They also feature superior screw-holding capacity and excellent surface finish. This makes them suitable for heavy-duty applications, such as making acoustic panels and high-quality furniture.

ECO-Friendly MDF

Eco-friendly MDF is manufactured using recycled wood fibers and materials. This reduces environmental impact and promotes sustainability. Eco-friendly MDF is popular among interior designers who love environmentally conscious practices. It is used in many applications, such as making furniture and cabinetry.

Plain Medium Density Fiberboard (MDF) is the most used type of MDF in the market. It is popular among woodwork manufacturers and designers because it is easy to use, inexpensive, and offers high versatility for different applications. This board can be used to create customized furniture designs or as a backing for other furniture items.

It is an engineered wood product made from wood fibers, wax, and resin bonded under high pressure, creating a dense, smooth, and flat board. This board has different sizes and thicknesses. It can be cut into various sizes to suit the needs of a particular project. It is available in 3/16 inches, 1/4 inches, 1/2 inches, 3/4 inches up to 1 inch and more.

The board's thickness depends on the application for which it is used. For example, thinner boards are used for drawer sides and cabinet panels, while thicker ones are used for tabletops and shelving units. Medium-density fiberboard has several features and functions that make it a highly sought-after material for many applications. These include:

Medium Density Fiberboard (MDF) is a versatile engineered wood product. It's made from wood fibers bonded together with heat and pressure. This process results in a smooth, dense board that's easy to work with. Here are some common applications of plain medium density fiberboard:

Furniture Construction

MDF is widely used in furniture such as cabinets, shelves, dressers, and desks. The smooth surface of the MDF accepts veneers and laminates well, allowing the creation of custom furniture with various finishes. MDF is cost-effective for mass-producing ready-to-assemble (RTA) furniture.

Interior Applications

MDF is used to create decorative moldings and trim, such as baseboards, crown moldings, chair rails, and window casings. This allows for the addition of architectural details to walls and ceilings at a low cost. Wall panels and wainscoting made of MDF improve interior spaces.

Cabinetry and Storage Solutions

Dressers, desks, and closet systems are made of MDF, providing a solid foundation for doors, drawers, and shelves. The smooth surface of the MDF is well-suited for laminate or paint finishes, making custom cabinetry affordable and appealing.

Decorative Elements

MDF is used to make decorative wall art and mirrors. Lightweight MDF frames are easy to hang and transport. The smooth surface of the MDF is well-suited for various finishes, including paint, veneer, and laminate. This allows for the creation of custom furniture pieces with a wide range of appearances.

Soundproofing and Acoustic Panels

MDF boards are used to make soundproofing panels and acoustic tiles. These products reduce noise in residential and commercial spaces. The dense surface of the MDF absorbs sound waves, improving the overall acoustics of a room.

DIY Projects

MDF is a popular choice among DIY enthusiasts due to its ease of use and affordability. Small projects like picture frames, shelves, and storage boxes can be made easily using plain medium density fiberboard.

When choosing the right plain medium density fiberboard (MDF), there are several factors that should be considered to ensure the selected MDF meets specific needs and requirements. Here are some tips that should be considered:

Consider the application

It is important to first identify the intended application of the MDF board. In most cases, MDF boards are used for different purposes, which means the application will influence the type of MDF board to go for. For instance, if the board is intended for furniture construction, a plain MDF board will suffice. However, if it is meant for high-traffic areas, then a durable MDF board should be considered.

Consider the thickness and density

Medium density fiberboard comes in different thicknesses and densities. It is important to choose the right thickness and density to avoid compromising the structural integrity of the final project. For instance, a thicker board is more stable and less prone to bending and warping, while a denser board offers better durability and strength.

Consider the finish

Plain MDF boards are compatible with different finishes. It is important to choose an MDF board that is compatible with the desired finish. Some boards have a smooth surface that allows for easy painting and veneering, while others have a textured surface that is ideal for laminate application.

Consider the Cost

Cost is an important factor when choosing an MDF board. As a buyer, it is important to choose an MDF board that is within budget. Fortunately, these boards are affordable, and considering the cost does not compromise quality.

Consider the environmental factors

When choosing an MDF board it is important to consider the environmental factors. This is especially important when the project is located in an area with extreme environmental conditions. For example, if the project is exposed to high levels of moisture, then it would be important to choose an MDF board that is highly durable and waterproof.

Q1: What is the lifespan of MDF boards?

A1: Medium density fiberboard does not have a specific lifespan. Instead, it lasts as long as possible when used correctly. Therefore, users should avoid exposing the MDF boards to extreme moisture, heat, and direct sunlight. Also, avoid placing heavy loads on the boards.

Q2: Are MDF boards worth my money?

A2: MDF boards are more than worth their money. They are a cost-effective option, easy to work with, and versatile.

Q3: What is the best surface treatment for my MDF boards?

A3: Almost any surface treatment can be applied to the plain medium density fiberboard and it will work perfectly. Treatments include paint, melamine, veneer, and laminate.