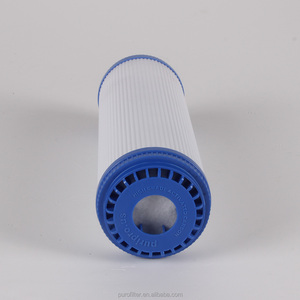

Types of pleated high-flow sediment filters

A pleated high-flow sediment filter is a kind of filter that works to trap and remove sediment from water and other fluids. They are designed to handle a larger flow rate. The type comes in different kinds designed for unique applications. Some of them include;

- Polypropylene (PP) pleated filters: These high-flow pleated filters are made with melted and drawn polypropylene material. They are strong enough to filter out sediment in agricultural irrigation, ballast water treatment, and industrial process waters.

- Polyethylene (PE) pleated filters: These kinds of sediment filters are well-placed inside housings. They filter and remove all types of sediment from reverse osmosis prefilters, beverages, and point-of-use drinking water applications. The sinew inside PE pleated filters will deliver excellent turbidity and particle removal.

- Wire mesh pleated filters: The pleats on this type of sediment filter are made with woven stainless steel wire mesh. It can withstand extremely high temperatures and pressures. That makes it perfect for applications that require the removal of large particles from corrosive fluids.

- Nomex® pleated filters: This kind of sediment filter is specially used to filter out dust and other kinds of particulates from oil mist and chemical fumes. The filters can withstand extremely high temperatures (up to 220°C). They are often used in pleated dust collector cartridges.

- PVC pleated filters: The PVC pleated filters are used to filter water, air, and other fluids under relatively low temperatures and pressures. They are strong and resistant to corrosion, chemicals, and rust because they are made from PVC. These filters will provide excellent sediment filtering for light-duty applications.

Functions and features of pleated high-flow sediment filters

Pleated high-flow filters have various excellent properties that make them popular in industrial fluid filtration. They have a large filtration area due to their pleated design. This means they can trap more particles and extend their service life. These filters also have a high dirt-holding capacity. They can remove a lot of suspended solids from the fluid before replacement. This filter is more cost-effective since users don't need to replace it regularly.

The filters have a multi-layered structure that allows for effective particle removal. Different sediment filter cartridges also work well under different pressures. These filters can work under high pressure to meet industrial requirements. They have a pressure drop at a very high flow rate. Users in applications where fluids need to be moved quickly prefer these filters.

High-flow pleated filters are solid integral components for fluid systems. They remove impurities at a high flow rate. These filters also have a compact construction. They take up less space in filtration systems. This makes them a suitable choice for workplaces with limited space.

- Large surface area: High-flow sediment filters have a large filtration area. They can handle higher flow rates for effective filtration.

- Geometric configuration: These filters have a pleated or woven configuration trap particles more effectively.

- Pressure drop: They maintain a consistent pressure drop to reduce system energy costs.

- Sediment filters hold capacity: These filters have a higher dirt-holding capacity. They can remove more solids before disposal or replacement.

- Compact size: High-flow filters have a compact design. They take up less space in the filtration systems.

- Optimized flow path: This improves sediment filters efficiency and reduces the risk of clogging.

Applications and uses of pleated high flow sediment filters

Pleated filters are commonly used in numerous industries and applications due to their reliable performance and high filtration efficiency.

- Potable water treatment: These filters are used in municipal water treatment facilities to assist in clarifying and filtering sediment to ensure that the water consumed is clean and safe.

- Aquaculture: In aquaculture facilities, pleated filters clean the water by removing pollutants, organic matter, and any kind of sediment from the water for healthier fish and shellfish farming.

- Industrial process: Many industrial processes require the use of pleated filters to lint or filter the liquids and prevent sediment from clogging up, damaging or impacting the quality of the end products. Such industries include petrochemical, pharmaceutical, and food and beverage industries.

- Cooling tower: High-flow pleated sediment filters can be used in cooling tower applications to filter out particulates and prevent them from clogging heat exchange equipment and suppressing the cooling efficiency of the tower.

- Pre-filtration for reverse osmosis: These filters can serve as pre-filters to RO systems and or other high-purity water production systems to protect membranes and other process components from particulates and thereby extending their useful life.

- Groundwater remediation: High-flow pleated filters are used in environmental applications for groundwater remediation to filter out sediments, particulates, and other contaminants from the groundwater in order to help with the treatment processes and restore the natural groundwater quality.

- Marine applications: They find use in various marine applications like ballast water treatment, vessel wash down, and engine cooling to aid in removing sediment and plankton from the ship's ballast water for compliance with the regulations.

- Mining and mineral processing: In the mining and mineral processing industry, high-flow pleated filters are vital in filtering out sediments, slurries, and particulates from the water used in various processes for enhanced efficiency and reduced wear on equipment.

- Polymeric and cell culturing: In laboratory applications and research involving cell and polymeric culturing, high-flow sediment filters are used to sterilize culture media and remove particulates to provide clean and optimal culturing conditions.

How to choose pleated high flow sediment filters

A filter's maximum contaminant load should be matched to the specific application to avoid premature filter replacement. Users must consider whether they need a disposable or reusable filter cartridge. Reusable cartridge filters are a cost-effective option for users because they can remove sediments through backwashing.

Users must also consider the filter's micron rating and pore size. A higher micron rating means the filter can remove larger-sized particles. Filter cartridges with a lower pore size provide higher-quality filtered liquid. Cartridge or pleated water filters are ideal for discerning filtration needs. They provide multiple filtration stages to remove specific contaminant types. Users must also consider the filter's absolute or nominal micron rating. Absolute rating filters provide consistent particle retention, while nominal-rated filters offer generalized filtration.

High-flow filtration applications require filters with minimal pressure drops. These filters have larger inlet and outlet connections to reduce fluid turbulence. User should consider the filter construction to ensure it can handle their specific application. Ten-inch pleated filters are suitable for compact spaces, while larger filters provide more surface area for filtration.

Q&A

Q1. How frequently should pleated sediment filters be replaced?

A1. Replacement frequency depends on the filter, water quality, and usage. Check manufacturer guidelines and monitor pressure drop or sediment levels for timing.

Q2. Can these filters be cleaned and reused?

A2. Some filters are self-cleaning or washable for multiple uses. Check filter specs to see if it is cleanable.

Q3. What industries commonly use pleated filters?

A3. They are used in many sectors like water treatment, food and beverage, pharmaceuticals, oil and gas, power generation, pulp and paper, and chemical processing.

Q4. Do pleated filters need to be stored in a controlled environment?

A4. Filters should be kept dry and clean. Excessive humidity or dirt may damage some filter media.

Q5. What happens if a sediment filter is not replaced?

A5. Failure to change a clogged filter can result in reduced water flow, pressure drops, and impure water, which may cause equipment damage and increased costs.