(485 products available)

A pneumatic cylinder 800 mm is an industrial mechanism that uses compressed gas to generate linear movement. Generally, these devices are classified according to their structure and working method.

rods

A rod pneumatic actuator has an internal shaft known as a piston connected to a reciprocating rod. When compressed gas enters the cylinder, it pushes or pulls the rod to create movement. This type of cylinder is simple and has a wide application range. However, their stroke length is usually limited to less than double the rod's diameter.

Guided Cylinders

Guided rod cylinders possess bearings that support the rod. This allows the cylinder to move more smoothly and precisely. Additionally, guided rod cylinders can support heavier loads and resist side loads better than unguided ones.

Since they are always under more strain, guided cylinders usually have quicker lifespans than unguided ones. Thus, taking proper maintenance measures can help them last a very long time.

No Rods

Also known as a rodless cylinder, this type of pneumatic cylinder does not have a protruding rod or shaft. Instead, they contain a moving element within the housing that travels the length of the cylinder. This design allows for longer strokes in a more compact body. Furthermore, rodless cylinders can be mounted in various directions and places.

Double Acting Pneumatic Cylinder

A double-acting air cylinder has two active areas – one for pushing and the other for pulling. Compressed air enters the cylinder through two ports to push the piston out and bring it back in. This type of cylinder can be used in places that require high force and speed.

Single Acting Pneumatic Cylinder

A single-acting pneumatic cylinder has one active area and uses a spring to return the piston to its original position. These cylinders are suitable for lighter loads and lower speeds.

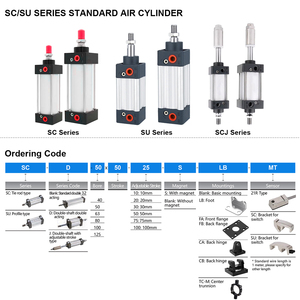

Sizes As per Bore Size

Pneumatic cylinders are available in various bore sizes, ranging from 25mm to 800mm or even larger in some cases. The stroke length can range from 10mm to 2000mm or more.

Force Calculation

The force generated by a pneumatic cylinder is calculated by multiplying the cylinder's area by the air pressure (Force = Area x Pressure).

Duty Cycle

The duty cycle of a pneumatic actuator is the percentage of on time to the total cycle time when the cylinder is in use. It is essential to monitor the duty cycle to prevent overheating the air compressor.

Pneumatic cylinders require regular maintenance to keep them in good operating conditions and ensure long-term use. Here are some maintenance tips:

Regular cleaning

Use clean water and neutral detergent to wipe the outer surface of the cylinder. Avoid using abrasive sponges or detergents to prevent scratches and damage to the cylinder surface.

Keep the cylinder dry

Keep the interior of the cylinder dry and avoid moisture and foreign matter to prevent corrosion and damage to the seal.

Regular lubrication

Apply appropriate lubricants to the moving parts and sealing elements of the pneumatic cylinder to ensure smooth operation and reduce wear.

Check the seal

Regularly inspect the seals of the pneumatic cylinder for damage, deformation, or leakage. If any issues are found, they should be repaired or replaced in a timely manner to avoid air leakage and loss of pressure.

The 800 mm pneumatic cylinder is commonly used in a few industries. Here are the common applications for an 800 mm pneumatic actuator.

Industrial Automation

A long-stroke cylinder like the 800 mm actuator is great for achieving specific motions in an assembly line. The actuator can create precise and controlled linear movements. An example is using it to move a component over a fixed distance. It can also serve well in an application that requires moving at high speed and frequency.

Packing and Filling Machines

The 800 mm stroke cylinder is useful in packaging machines. It can perform key tasks like pushing,stractching,sealant application, and filling. This cylindrical actuator works great with machines such as bottling systems, cartoning, and labeling devices.

Heavy Duty Material Handling

The 800 mm pneumatic actuator can carry, lift, or push around heavy loads. This makes it suitable for use in material handling equipment. Examples include stackers, conveyers, and automated guided vehicles (AVGs). It provides strong gripping actions when handling heavy loads thanks to its high force-generating ability.

Machine Tools

Pneumatic cylinders are common in machine tool industry. They perform key activities like clamping, cutting, and hopper loading. The cylinder works well for machining centers, lathes, and milling machines. A specific machining centers application is precisely positioning a workpiece. This is done with high speed and great control.

Automotive Assembly

The automotive industry may use the 800 mm pneumatic actuator in assembly and production lines. It carries out key activities like inserting, aligning, or door loading. One specific application is inserting components or aligning vehicle parts together. This is done with high precision and at a fast speed.

There are many ways in which choosing the correct 800 mm pneumatic cylinder can be made easier by following a few simple tips. Start by getting an application of the task at hand. Knowing the application will assist in deciding the features of the cylinder that need to be prioritized.

Next, it's important to determine what kind of force generation and motion is required in the application. Once the force and type of motion are known, it will be easy to decide on the type of cylinder that suits the requirements of the task. The environment that the cylinder will be used in should also be considered. As discussed before, some tasks may require an explosion-proof cylinder because the environment cannot control static electricity. The mounting and dimensions of the cylinder are also important to consider. Obstacles in the workspace may require a different type of mounting or dimension to ensure the smooth functioning of the work.

Finally, take a look at the media compatibility with the task at hand. If the media from which or in which the cylinder will be working is not compatible with the cylinder, then failure or malfunction will occur. The pressure and temperature in the workspace should also be taken into consideration to see if they are in line with the functioning of the cylinder to prevent any kind of mishaps.

Q1: What is the working pressure range of an 800 mm pneumatic cylinder?

A1: The working pressure of a standard 800 mm pneumatic cylinder is usually between 1 and 1.5 MPa. Some heavy-duty cylinders can reach up to 2 MPa.

Q2: Can custom 800 mm cylinders with different sizes be made?

A2: Yes, many manufacturers can make custom 800 mm cylinders with different sizes, such as length, diameter, or other specifications to meet distinct requirements.

Q3: What are the benefits of using an 800 mm pneumatic over other types of cylinders?

A3: The major benefit of an 800 mm pneumatic cylinder is the high force output it can produce. Additionally, it has a simple design that enables straightforward installation, operation, and maintenance.

Q4: What are the closure methods of an 800 mm pneumatic cylinder?

A4: The closure methods of an 800 mm cylinder include tie rod, integrated block head and foot, and mobile flange.