(3236 products available)

Polyethylene in India is a popular thermoplastic polymer. It's used in packaging, containers, plastic bags, and bottles. Other applications include geomembranes, toys, and wire insulation. It is also one of the most widely produced plastics globally.

Polyethylene is produced by the polymerization of ethylene monomer. Ethylene is obtained from petroleum. Polyethylene is also known for its toughness, flexibility, and low-density characteristics. It is further classified into different types based on its manufacturing process, density, and branching.

Polyethylene is widely used and has various applications in different industries due to its versatility and desirable properties. Here are some major applications:

Packaging

Polyethylene is popularly used in packaging materials like plastic bags, film wrappers, and containers. Its flexibility, lightweight, and durability make it a suitable packaging material. Additionally, its resistance to moisture makes it widely used in the manufacture of grocery bags, trash bags, and food storage bags.

Bottles and Containers

Polyethylene is used in the manufacture of containers and bottles. Products such as milk jugs, detergent bottles, and water storage containers are manufactured using polyethylene.

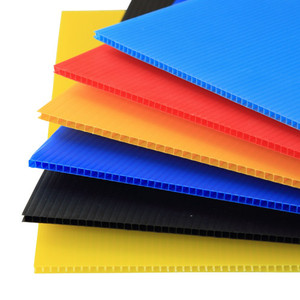

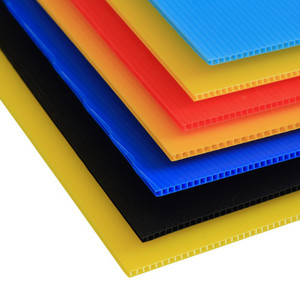

Films and Sheets

Polyethylene is used in the manufacture of plastic films and sheets. Low-density polyethylene (LDPE) is commonly used in this application due to its flexibility and ability to produce thin films. These sheets and films are used for greenhouses, construction, and wrapping materials.

Construction

Polyethylene is used in construction in different ways. It can be used as a moisture barrier to prevent water from getting into a building. It is also used in the construction of landfills as a liner to prevent waste from leaking into the ground. Additionally, high-density polyethylene (HDPE) is used in the manufacture of corrugated pipes for drainage and sewage systems.

Insulation

Due to its electrical properties, polyethylene is used in electrical insulation. It is also used as insulation material in the manufacture of cables and wires.

Textiles

Polyethylene terephthalate (PET) is a type of polyethylene widely used in textiles. It is used in the manufacture of clothing, carpets, and upholstery. Additionally, it is a durable and easy-care fabric.

Toys and Household Goods

Polyethylene is used in the manufacture of toys and household goods. Products such as plastic furniture, kitchenware, and children’s toys are manufactured using polyethylene.

Automotive Parts

Polyethylene is used in the manufacture of different automotive parts. Bumpers, interior trim, and fuel tanks are manufactured using polyethylene. Its lightweight and durable properties make it a suitable automotive parts material.

There are several applications of polyethylene in India, including:

When sourcing for polyethylene in India, there are several factors that wholesalers and retailers should consider to ensure they meet their customers' needs. Here are some of them:

Application and Product Type

Different applications require specific types of polyethylene. For instance, LDPE is used in packaging films and bags, while LLDPE is preferred for making durable and puncture-resistant bags. HDPE is suitable for containers, bottles, and chemical-resistant bags. Wholesalers should analyze the local market to determine the most preferred type of polyethylene products before placing their orders. They can source for bulk plastic films, plastic containers and lids, garbage bags, trash liners, or any other product that is in demand.

Quality and Standards

The quality of polyethylene products greatly influences customer satisfaction. Wholesalers should look for suppliers who provide products that meet local and international industry standards. They can request for product samples to access their quality before placing a huge order. They can also check the ratings and reviews of the supplier to get insights about their reliability.

Supplier's Experience and Reputation

Business owners should pay attention to a polyethylene supplier's experience and reputation. An experienced supplier understands the market needs and will deliver products that meet various expectations. They should also check the reviews and testimonials of previous clients to gauge the supplier's reliability.

Sustainability

As environmental concerns continue to grow, sustainable practices are becoming more common in the plastics industry. Business owners should consider suppliers who use eco-friendly practices in the production process. They can also look for suppliers who provide recycled polyethylene products or products that are 100 percent recyclable.

Customer Support and Communication

Reliable customer support and effective communication are essential for a smooth sourcing process. Wholesalers should choose suppliers with a dedicated support team that is easily reachable. They should be able to address any concerns and provide timely responses when called upon.

Delivery Time and Logistics

Timely delivery is crucial in order to meet customers' demands. Wholesalers should discuss the lead time with the supplier before placing an order to ensure it is realistic and attainable. They should also inquire about the shipping methods and logistics to determine how the products will be delivered and the estimated delivery time.

Q1: What are the major challenges facing India's polyethylene market?

A1: Major challenges include dependence on imported crude oil for production, fluctuating global oil prices affecting costs and profits, and environmental concerns over plastic waste. While polyethylene is widely used in packaging, construction and other applications, India's recycling rates are still low. This creates long-term challenges as the government aims for a circular economy.

Q2: Are there opportunities for growth in India's polyethylene market?

A2: Yes, there are significant opportunities for growth. Demand for polyethylene is rising due to India's growing population and economy. As infrastructure projects are implemented, construction materials like polyethylene will be needed. There is also potential for recycled and bio-based polyethylene as the government promotes sustainable practices and reduces plastic waste. Innovations in production methods and materials can boost the market further.

Q3: What are the types of polyethylene?

A3: There are two main types of polyethylene: high-density polyethylene (HDPE) and low-density polyethylene (LDPE). HDPE is more durable and used for containers, bottles, and pipes. LDPE is softer and more flexible, used for plastic bags, film wraps, and squeezing bottles.

Q4: What is the difference between polyethylene and plastic?

A4: Polyethylene is a type of plastic, specifically a polymer made from the monomer ethylene. Plastics are a broader category that includes various synthetic or semi-synthetic polymers like polyethylene, polypropylene, PVC, and more.

Q5: Is polyethylene recyclable?

A5: Yes, polyethylene is generally recyclable. However, the recycling rates vary depending on the type - HDPE has higher recycling rates than LDPE. Properly labeled and clean polyethylene products are usually collected for recycling.