(342 products available)

PQ bobbins come in different types, each suitable for specific industrial applications.

Large Core Bobbin:

Large core PQ bobbins are designed for high-volume production runs. They have a large inner diameter, which allows more output of threads or other materials. This reduces downtime, as fewer changes are needed during the production process. These bobbins typically have a larger, thicker, spool-like shape and can hold up to three times the amount of thread as standard bobbins, making them ideal for industries such as textile manufacturing, where efficiency is key. Additionally, their sturdy design helps prevent tangles and maintains consistent feeding of the material.

Small Core Bobbin:

Small core PQ bobbins suit businesses with limited space or lower production volumes. They are easier to store and handle due to their smaller size. Like large core bobbins, small core bobbins are manufactured to fit modern sewing machines. They can hold enough thread for simple projects, repairs, and domestic sewing. However, users may need to change them more frequently compared to large core bobbins.

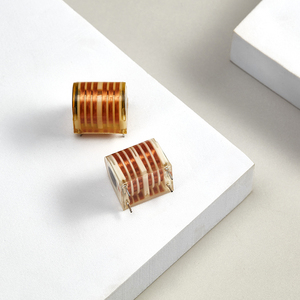

Plastic PQ Bobbin:

Plastic PQ bobbins are more common in the market. They are more affordable than their metal counterparts and are designed not to rust or corrode with time. Plastic bobbins are light and ideal for everyday use. Most modern sewing machines require them as they are made to fit perfectly and work smoothly. Plastic bobbins also come in pre-filled formats, saving customers time and effort when loading thread onto the bobbin.

Metal PQ Bobbins:

Metal PQ bobbins are heavier and provide more stability to the thread rotation. Although they are slightly bulkier than plastic ones, they are not easy to misplace owing to their weight. Their durability is a standout feature, ensuring they withstand frequent use. Metal bobbins are suitable for heavy-duty sewing tasks or specialized applications where precision and reliability are paramount. Despite their weight, they provide a seamless sewing experience and are compatible with various sewing machines.

The following are some critical specifications for PQ bobbins:

Mishandling can lead to dirty, broken, or damaged bobbins. Here are some handy tips on how to clean, repair, or recycle them:

Textile Industry:

In the textile industry, specifically in weaving workshops, weaving factories, or clothing making facilities, the primary application of PQ bobbins is to support textile threads. With the assistance of PQ bobbins, textile machines like looms, sewing machines, and embroidery machines can run smoothly and continuously, ensuring the quality of the products.

Sewing and Embroidery:

In sewing and embroidery workshops or clothing production lines, embroidery machines and sewing machines also need to use bobbins. These machines usually require different materials and threads, such as silk threads, leather threads, and bonded threads. Using a specific type of bobbin can ensure that the machine runs smoothly, the thread tension is appropriate, and the sewing or embroidery quality is high.

Carpet and Drapery Production:

In carpet and drapery production workshops or related manufacturing companies, large-capacity bobbins are commonly used to meet the demands of high-volume production. These bobbins can hold more textile threads, thereby reducing the frequency of replacement and downtime during the production process, improving production efficiency, and ensuring product quality.

Quilting and Knitting:

In quilting and knitting workshops or fixed facilities, specialized bobbins might be required, such as digital bobbins or quilt bobbins. These specific types of bobbins are designed to cater to particular equipment or techniques, thus satisfying distinctive production needs.

There are many ways to choose the proper bobbins for sewing machines. The first one is to match them precisely to the sewing machine and ensure they are compatible. Consider the kind of material, preferably buying those made of high-quality plastic or metal, which have good performance.

Think about the amount of thread capacity required for the projects. For small and simple projects, it is better to use PQ bobbins with less thread capacity, but for more significant and complex projects, it is better to use PQ bobbins with more thread capacity. Choose the right size according to the manufacturer's recommendations or standard guidelines.

If storing bobbins is a concern, choose a bobbin that can fit well in the bobbin holders. For businesses that have many PQ bobbins, it is better to pick the ones that are easily identifiable and can be labeled. This will help in easy identification and swift retrieval during use.

When selecting PQ bobbins for resale, consider choosing different types to accommodate different customers' preferences. It is best to buy PQ bobbins in bulk to reduce the overall cost. If not sure about the demand, it is better to start by purchasing small quantities. Also, ensure to select the ones that have good quality and can last for a long time. Finally, do research on different suppliers and compare prices and qualities before settling for one.

Q1: How does a sewing machine bobbin work?

A1: The sewing bobbin stores the lower thread, which interlocks with the top thread. This interlocking creates a stitch. The bobbin rotates and releases the thread as the sewing machine needle moves up and down.

Q2: Why is it called a bobbin?

A2: The term “bobbin” is believed to be derived from the Middle English word “bobbyn,” which means a small round object. Another theory suggests that it comes from the word “bob,” which means to move up and down or to dance. The words “bob” are used to describe the circular motion that bobbins do.

Q3: What are the signs of a damaged or worn pq bobbin?

A3: Look for cracks, frays, or uneven wear. Damaged bobbins can damage threads or the sewing machine hook.

Q4: Can one use aftermarket PQ bobbins?

A4: It's best to use manufacturer's recommended bobbins, as aftermarket ones may not fit or work correctly.