(1417 products available)

Scrap metal waste containers are large receptacles designed to hold and store scrap metal within a facility or at a construction site. These containers are an integral part of a site's waste management system, helping to keep areas tidy by grouping different kinds of scrap metal for recycling or disposal. Typically, these containers are made from strong materials like steel to withstand the wear and tear of heavy use and the weight of metal scrap. They come in various sizes and types, such as dumpsters or bins, which can be moved around easily with cranes or trucks. Having dedicated places like scrap metal waste containers is crucial for following safety rules, keeping costs down, and minimizing the environmental impact of metal waste.

These containers are essential for any industry dealing with metal because they enhance safety by lessening the risk of accidents caused by loose scrap lying around and ensuring that workers handle potentially dangerous materials in a controlled environment. Using these containers reduces site clutter, thus lowering the chances of workplace injuries. Moreover, it is much simpler and more efficient to gather, transport, and recycle metals when they are stored in designated containers. This efficiency is vital for businesses since recycled metals often have higher market values than non-recycled ones, making it financially worthwhile to reclaim them through scrap metal waste containers.

There are various types of scrap metal waste containers. Some of them are briefly described below for a better understanding.

Metal bins

Metal bins are robust containers typically made from galvanized steel to collect and store scrap metal. These bins come in various sizes, ranging from small units capable of holding several hundred kilograms of scrap metal to large containers designed to accommodate tons of waste. Metal bins can be lifted and transported to different sites using cranes or other lifting equipment. They are commonly found in manufacturing plants, automotive garages, and construction sites, offering a practical solution for managing metal waste. Cleaning up metal bins is essential for efficient recycling, as it ensures the separation and proper processing of different types of metals.

Metal dumpsters

Metal dumpsters are large, durable containers designed for collecting and storing scrap metal waste. Typically constructed from robust materials like steel, these dumpsters can withstand heavy usage and the weight of the metal. They come in various sizes to accommodate different amounts of metal waste and are commonly used in industrial settings, construction sites, and commercial enterprises. Metal dumpsters are emptied and replaced with empty ones by waste collection vehicles, allowing for efficient disposal or recycling of the collected scrap metal.

Metal compactor containers

These containers are large and strong, making them ideal for holding heavy metal scraps. They have a compacting system that reduces the size of the collected metal waste. This is especially useful for businesses generating a lot of scrap metal, as it saves space and makes it easier to transport the waste for recycling. Furthermore, compacting it can lead to lower costs and better environmental results because less room is needed in landfills, and compacted material is often cheaper to move.

Roll-off containers

Roll-off containers are large metal bins often used on construction sites or in industrial areas to collect scrap metals. When full, these containers can be rolled off and replaced with empty ones by special trucks. They come in various sizes, making them suitable for different amounts of waste. These containers are convenient for managing large volumes of scrap metal, ensuring that sites stay clean and safe by collecting and removing waste efficiently.

Front-end load containers

Front-end load containers are metal receptacles designed for collecting and disposing of scrap metal waste. These containers are emptied using a front-loading mechanism on the truck, which means the container opens at the front for waste collection. They are strong and often seen in urban areas or commercial settings where space is limited but efficiency in waste management is required. They help keep places tidy by making it easy to throw away and recycle scrap metal, which can be valuable and environmentally friendly to recover.

Designing scrap metal waste containers is a complicated procedure that requires careful consideration of several parameters in order to provide efficient storage and disposal of scrap metals. The following is an overview of the important design aspects of these containers.

Purpose and Functionality:

The main purpose of these containers is to hold scrap metals safely and efficiently. They are designed to store different kinds of scrap metal waste, like chips, shavings, and pieces from machining, welding, or construction work. They help keep work areas clean by collecting metal waste in one place.

Material Selection:

Since these containers collect metal waste, they must be made from strong materials that can handle heavy weights and rough treatment without breaking. Common choices are thick steel or stainless steel because they do not rust even when wet with water or other liquids.

Shape and Size:

The shape and size of a scrap metal container depend on where it will be used and how much waste it might collect over time. Usually, these containers are designed to be square or rectangular so that stacking them neatly does not waste space inside or outside buildings. They can also be larger, like dumpsters, for outside areas.

Open-Top Design:

Scrap metal containers typically have an open-top design. This makes putting large or heavy items inside easier. It lets workers quickly dump metal waste without worrying about anything slipping from the container's edges.

Reinforced Edges and Corners:

To stop damage caused by heavy loads or rough handling, the edges and corners of scrap metal containers are reinforced. Extra material is added in these places to strengthen them and ensure the container lasts a long time.

Handles and Lifting Features:

Handles on the sides of smaller containers make moving them easier. For bigger containers, lifting equipment like hooks or straps is needed. This means both large and small containers can be safely transported to where they are full using different tools.

Drainage:

Some scrap metal containers have holes at the bottom at special places at the bottom. These holes allow any liquids that may collect inside from wet metals or rainwater to drain out through them so that the container does not overflow or become too heavy.

Stackability:

For smaller metal containers, the designs allow them to be stacked on top of each other when empty. This helps save space during storage until needed again.

Wheeled Options:

Some containers come with wheels. These wheels make moving even heavy scrap metal containers easy over long distances within a workplace. It reduces the effort required to shift things around.

Compliance with Regulations:

Designers must ensure that all aspects of the container meet local rules about safety standards, including how close it should be to the ground so that no one accidentally walks into it from behind. These regulations help protect workers and the environment.

Metal containers are strong, durable, and can be used in a variety of scenarios. They are especially useful for storing and transporting large quantities of scrap metal waste. Some of the common usage scenarios for these containers include:

Storage and transportation

Metal scrap containers are often used for storage and transportation of scrap metal. They can be used in factories and industries to store metal waste until it is disposed of. They can also be used to transport scrap metal from one place to another. For example, a dumpster can be filled with stored scrap metal and then transported to a recycling center for processing.

Collection

These containers are also used for collection purposes. In many places, there are dedicated collection points where people can drop off their metal waste. The collection points are usually equipped with large containers that can hold a significant amount of scrap metal. Once the containers are full, they are emptied by the waste management company.

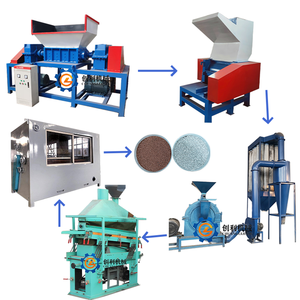

Processing at recycling centers

Recycling centers use metal scrap containers to store and process incoming metal waste. These centers have large containers to collect aluminum cans, old appliances, vehicles parts, and other discarded metals. Inside the recycling center, the scrap metal from these containers is sorted, cleaned, shredded, and melted down so that it can be reused to make new products.

As temporary storage during construction or demolition

During construction projects or when buildings are being torn down (demolition), metal containers are sometimes used as temporary storage units for all the leftover materials. Instead of leaving pieces of old pipes, wires, beams, and other metals lying around on the ground where someone could get hurt, these containers keep everything safely contained in one place until it can be properly disposed of or recycled.

Safely managing hazardous waste

Some hazardous wastes like old batteries or mercury-containing lights must be handled with extra care due to their potential danger to people and the environment. Specialized metal scrap containers designed for hazardous materials are used. These containers have secure lids and labels warning about what type of dangerous waste they hold. This prevents any leaks from occurring that could harm anyone or contaminate land/water sources.

For one thing, the type of scrap metal is an important consideration. Different metals generate varying degrees of weight and sharp edges. For heavy steel scrap, a robust and durable container capable of withstanding the weight and potential damage is required. On the contrary, a container for aluminum or copper should prioritize lightweight design and ease of handling. Also, choose a container that can accommodate the specific metal being collected.

For another thing, the environment in which the container will be used should be taken into account. If it is used outdoors, it must be able to stand up to different weather conditions. Moreover, it should be resistant to corrosion, especially if it is used in a coastal area or an industry with high humidity. On the other hand, if the container is used indoors, the focus should be on its space utilization and mobility. It should be easy to move and place in different areas of the workshop.

Furthermore, the container's capacity and size ought to be in line with the volume of scrap metal generated and the available space. A larger container can hold more scrap, reducing the frequency of collection and disposal. However, it should not occupy too much space, so it is convenient to move within the workshop. Also, the design of the container should facilitate the easy and safe disposal of scrap metal. It should have wide openings to allow for the quick and simple deposition of scrap and prevent overflows.

Q1: Can metal containers hold hazardous waste?

A1: Yes, scrap metal waste containers can collect hazardous waste. Some containers have special features to hold dangerous things safely. These features include tight seals and strong materials.

Q2: How often should containers be emptied?

A2: The frequency of emptying containers depends on the amount and type of scrap metal generated. Containers should be emptied when they are full to maintain safety and efficiency.

Q3: What types of scrap metal can be collected in these containers?

A3: Scrap metal containers can collect various metals, including ferrous metals like iron and steel and non-ferrous metals like aluminum, copper, lead, zinc, nickel, titanium, etc.

Q4: How can businesses ensure the container is recycled?

A4: Businesses should work with waste management companies to ensure that the metal containers are recycled at the end of their life. Many companies have programs to recycle containers.

Q5: What are the environmental benefits of using scrap metal containers?