Sic Silicon Carbide: Introduction

Sic Silicon Carbide is a cutting-edge material that has transformed a wide array of industries, thanks to its exceptional thermal and mechanical properties. This compound, composed of silicon and carbon, possesses remarkable hardness and resistance to oxidation, making it ideal for demanding applications where performance and durability are paramount. As industries evolve and the demand for high-performance materials increases, SiC is emerging as a leading choice for manufacturers seeking to enhance their product line.

Types of Sic Silicon Carbide

Sic Silicon Carbide is available in various forms, each tailored for specific applications and industry requirements:

- Black Silicon Carbide: Known for its high hardness and is typically used for abrasive applications, such as grinding wheels and blasting media.

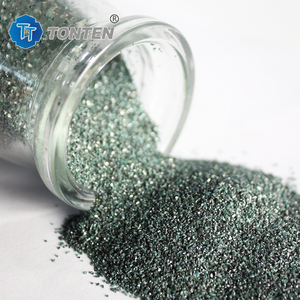

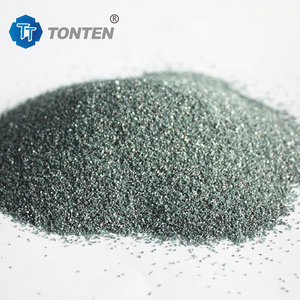

- Green Silicon Carbide: Offers even higher purity and is primarily used in the manufacture of advanced ceramics and semiconductor devices.

- Recrystallized Silicon Carbide: This variant is used for high-temperature applications and is popular in the production of kiln furniture and other refractory products.

- Sic Powder: Grinding down the SiC material into fine powders used for abrasives and coatings in various industrial applications.

Applications of Sic Silicon Carbide

The versatility of Sic Silicon Carbide extends to a multitude of applications across diverse sectors. Here are some notable examples:

- Aerospace: Utilized in turbine components and thermal protection systems due to its excellent thermal conductivity and high-temperature stability.

- Electronics: SiC is increasingly used in power electronics, including MOSFETs and diodes, providing superior efficiency and thermal management.

- Automotive: Engineered components, including brake discs and clutches, benefit from the lightweight and high-strength properties of SiC.

- Semiconductors: SiC wafers are crucial in the semiconductor industry, offering faster switching speeds and higher voltage tolerance than traditional silicon.

Features and Advantages of Sic Silicon Carbide

The distinct features of Sic Silicon Carbide contribute to its widespread adoption in various industries:

- High Hardness: One of the hardest materials available, making it ideal for abrasive applications.

- Heat Resistance: Superior thermal stability allows it to perform exceptionally well under high-temperature conditions.

- Chemical Inertness: Resistant to a broad range of chemicals, extending the lifespan of components made from SiC.

- Electrical Conductivity: Semiconducting properties enable high-performance electronic applications, making devices more compact and efficient.

- Lightweight: Lighter than many alternatives, reducing overall weight in applications where mass is a critical factor.

In conclusion, Sic Silicon Carbide stands out as a versatile, high-performance material widely utilized in modern technology. Its various types and applications, combined with its unique properties, make it an invaluable asset for industries seeking to push the boundaries of performance and efficiency.