(8915 products available)

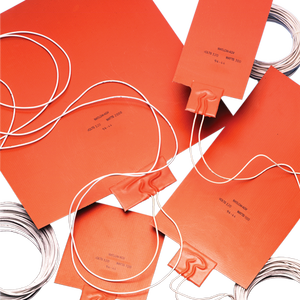

The types of silicone rubber flexible heater include the following.

Flexi heaters are very versatile, so many silicone rubber heater specs are available. The voltage diverts the current used for flexibility. Higher voltages use less current, resulting in a thinner heater. For example, 24 volts will use a higher current than 120 volts. The standard voltages are 12V, 24V, 36V, 48V, 60V, 110V, 120V, 220V, and 240V. They are usually thin, around 5 mm, and are available in diameters from 50 mm to 1,200 mm. Generally, the larger the heater, the higher the voltage needed. Custom heaters up to 3,000 mm are possible with higher voltages. The wattages vary between 5 W and 1,000 W for the silicone rubber flexible heater strip. The higher the wattage, the hotter it gets, but anywhere between 5 and 1000 watts should suffice for most applications. The operating temperature can range from -60°C to +200°C. This means they can work in very high and many low temperatures. Up to 20°C to 300°C is possible using special materials.

Maintaining silicone heating pads is pretty easy. When using silicone rubber heater mats, some critical care tips should be observed. First, avoid subjecting the silicone heater to risks that may cause it to kink or crush. On the flip side, if an incident like this occurs, immediately stop gearing up the heater and take a look at it.

Secondly, users shouldn't drill or puncture flexible silicone heaters for any reason, such as mounting holes or adding insulation. The third tip is to keep the heater clean always. Doing so will not only keep it looking good but will also fast track the process of finding and promptly addressing any signs of damage.

Fourth, store silicone heaters in a cool and dry place whenever they aren't in use. Also, avoid exposing them to moisture or standing water. Doing so can result in mold growth or deterioration of the material. More so, users shouldn't use chemicals or solvents when cleaning the heater, and when it gets dirty, the water and soap should be enough to do the job. Avoid exposing the silicone heater to open flames or excessive heat that can potentially damage the heater or create a fire hazard.

These types of heaters have many applications in different industrial/engineering and personal use areas.

Food production industry

Flexible heaters warm molds, dies, and extrusion barrels. They help to maintain consistent temperature during the processing of plastics. They also preheat pipes, valves, and fittings.

Aerospace and automotive industries

In the aerospace and automotive industries, silicone rubber heaters are used for thawing and de-icing components. They are also used to heat fluids and gaskets. In electric vehicles, silicone heaters are used to heat batteries to enhance their performance and longevity.

Medical industry

Flexible heaters are used in medical devices to provide controlled heating for applications such as warming IV fluids, warming blankets, and preventing hypothermia during surgeries.

Textiles and art industry

In the art and textile industries, silicone heaters are used for curing and drying fabrics in the process. Also, they are designed to provide heat for fiber art tool like polymer clay. They can facilitate faster curing and drying times for textiles and art pieces.

Construction industry

Flexible silicone heaters are used for thawing frozen ground and curing concrete. These molds help to accelerate the setting time of concrete and reduce the risk of cracking.

Automotive and aerospace industry

Flexible silicone rubber heaters are used to defog and de-mist windshields and windows in vehicles. They provide quick heating to eliminate moisture and enhance visibility. They are also used to warm up engines, transmissions, and other critical components to ensure smooth operation and reduce wear.

Packaging industry

In the packaging industry, silicone rubber heaters are used for inking and adhesion during printing processes. They also help to maintain consistent temperatures for packaging equipment. Additionally, these heaters are used for shrink wrapping and sealing to ensure precise and efficient packaging operations.

Electronics industry

In the electronics industry, silicone rubber flexible heaters are used for soldering and thawing electronic components. They provide controlled heating for delicate electronic parts, preventing damage during soldering and assembly. Silicone rubber heaters are also used for thawing frozen circuits and eliminating moisture from electronic enclosures, ensuring proper functionality and reliability.

Energy industry

In the energy industry, silicone rubber heaters are used for maintaining the temperature of pipes, valves, and tanks in refineries and power plants. They are also used for thawing frozen equipment and preventing condensation on sensitive electronic components and connectors.

Research and development

In research and development labs, silicone rubber heaters are used for prototyping and custom heating solutions. They provide flexible and adjustable heating for experimental setups, custom chambers, and incubators. These heaters enable scientists and engineers to develop and test new technologies and products in various fields.

Application:

Heaters made of silicone rubber are great for outdoor use because they perform well in cold. They can be used in the car, at home, or on machines outdoors. On the other hand, fabric flexible heaters are good for keeping areas sterile. They work well in hospitals, laboratories, and clean rooms where dirt should not be. The choice between the two depends on where the heater will be used.

Temperature control:

Some devices need exact heating. For such cases, silicone rubber heaters with temperature controls should be chosen. These heaters have sensors that can adjust the heat they produce.

Power source:

Flexible heaters can use AC power, which comes from the wall sockets, or DC power, which is like the power from a car battery. If the item to be heated runs on a battery, a DC silicone flexible heater would work better for it.

Size and weight:

Usually, soft heaters are lighter than hard heaters. It is easy to carry them. The weight and size of the heater should be looked at to find the one that adds little to the load of the device.

Connector:

Silicone connectors can be joined to connectors that are not silicone. However, the type of connector for any given application will influence what we choose.

Cost:

A flexible silicone heater's cost will depend on factors like its size, the materials used to make it, and special features like built-in thermostats or customized shapes. Heaters with more advanced features or larger sizes will generally be more expensive.

Q1: What are silicone rubber heaters made of?

A1: Silicone rubber heaters are constructed using three main components: The top layer is made of a high-quality silicone rubber, which is both moisture-proof and anti-pulling; the middle layer is the insulating layer, which is made of fiberglass cloth, plastic film, or other materials; The bottom layer is the base layer, which is also made of high-quality silicone rubber. It is used to protect the heating element and provide a surface for mounting the heater.

Q2: How do Silicone Rubber Flexible Heaters work?

A2: Silicone Rubber Flexible Heaters work by converting electrical energy into heat energy through the heating element. The heat is then uniformly distributed over the surface of the heater, providing consistent heating to the object being heated.

Q3: Why are silicone rubber heaters better?

A3: Silicone rubber heating pads have a higher power density than other flexible heater alternatives. They can heat up to 5W/cm2, which will reduce the heating time considerably. Silicone rubber heaters can be made thin (up to 0.5mm) or thick (up to 5mm) and die-cut into almost any shape, which makes them a perfect choice where space is limited.

Q4: What is the temperature range of silicone rubber heaters?

A4: The temperature range of silicone rubber flexible heaters generally is from -60 °C to +200 °C. But silicone rubber heaters with different maximum temperatures are available.