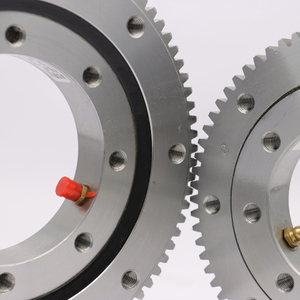

Introduction to Stainless Steel Turntable Slewing Rings

Stainless steel turntable slewing rings are precision-bearing components widely utilized in various engineering applications. These components are essential for facilitating smooth rotational movement while supporting heavy loads. Constructed from high-quality stainless steel, they offer exceptional durability and corrosion resistance, making them ideal for outdoor and industrial uses where exposure to harsh elements is a concern.

Types of Stainless Steel Turntable Slewing Rings

- Single Row Slewing Rings: These slewing rings feature a single row of rolling elements. Ideal for applications that require moderate load capacities and rotational movement.

- Double Row Slewing Rings: With two rows of rolling elements, these provide enhanced load capacity and stability, suitable for demanding operations.

- Four Point Contact Slewing Rings: This type allows for higher load capacities due to its unique design, making it perfect for applications with significant rotational demands.

- Ball Bearing Slewing Rings: Utilizing ball bearings, this design is effective in reducing friction, leading to smoother motion.

Applications of Stainless Steel Turntable Slewing Rings

- Construction Machinery: Slewing rings are commonly used in cranes and excavators, allowing for precise control and movement in heavy-duty tasks.

- Renewable Energy: In solar panel installations, these components enable the rotation needed for optimal sunlight exposure throughout the day.

- Marine Applications: Their corrosion-resistant properties make them ideal for use in ships and offshore structures where exposure to saltwater can be detrimental.

- Automotive Manufacturing: Used in assembly line equipment, they assist in the rotation of robotic arms and other automated functions.

Features and Advantages of Stainless Steel Turntable Slewing Rings

- Corrosion Resistance: Made from stainless steel, these slewing rings are not susceptible to rust and degradation, ensuring longevity in challenging environments.

- Ease of Installation: Designed for hassle-free installation processes, they can significantly reduce downtime and improve productivity during setup.

- Smooth Operation: The precision engineering of slewing rings guarantees seamless rotation, minimizing friction and wear over time.

- High Load Capacity: Available in various designs to support substantial weight loads, making them suitable for heavy machinery and industrial applications.

- Customization Options: Often available in different sizes and specifications, they can be tailored to meet specific operational needs and constraints.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4