(1580 products available)

Stock steel grating, or steel grid walkways, are available in different types depending on the application and environment. Here's an overview of the different types:

Bar Grating:

This type of stock steel grating is constructed with carbon steel or aluminum. It consists of parallel bars joined perpendicular by welded bars. The design offers a solid walking surface. The configuration of this grating allows light, air, and water to pass through. It is also customizable for different applications. This steel grating is used in industrial plants, power plants, and wastewater treatment facilities.

Safety Grating:

This stock steel grating is constructed using hot-rolled steel angles. It features a top surface of anti-slip material, which enhances traction. It also has a drain slot to reduce water accumulation and prevent slipping. The design of this safety grating provides superior slip resistance. It is also resistant to impact and abrasion. Additionally, it is ideal for high-traffic areas. This type of grating is used in factories, commercial kitchens, and emergency exits.

Press-Locked Grating:

This stock steel grating is constructed with hot-rolled steel. Its cross bars are pressed and locked into a rectangular frame. This construction technique enhances structural integrity and rigidity. It also creates a seamless surface without welds or bolts. These gratings have a high aesthetic appeal and are easy to install. They are also ideal for pedestrian walkways, bridges, and architectural applications.

Swage Locked Grating:

These stock steel gratings are constructed with carbon steel or aluminum. The main bars are swaged and locked with steel cross rods. This construction method creates a strong and stable grating. It also provides a lightweight solution with high load-bearing capabilities. These gratings are durable and require low maintenance. They are mainly used in heavy-duty applications, sewage treatment plants, and offshore platforms.

Fiberglass Reinforced Plastic (FRP) Grating:

This type of stock steel grating is made from resin and fiberglass. It is designed to be corrosion-resistant, lightweight, and non-conductive. It is also available in a variety of colors. These gratings are ideal for environments that require electrical insulation and chemical resistance. They are mainly used in chemical processing plants, pulp and paper mills, and marine applications.

Durability and Strength

Durability and strength are key features of stock steel grating. This allows for heavy loads and high-impact resistance. Stock steel grating is made from materials that have exceptional tensile strength. This means that stock steel grating can withstand bending or breaking under pressure.

Corrosion Resistance

Corrosion resistance is one of the key features of stock steel gratings. It ensures durability and longevity in different environments. Some stock steel grating undergoes a process called hot-dip galvanization. This creates a coating that protects it from rust and harsh weather conditions.

Versatility

Versatility is a key feature of stock steel grating. It makes it popular in different industries. There are different types of stock steel grating. Each of them has different applications. This includes pedestrian walkways, industrial flooring, stair treads, and drainage covers.

Customization

Customization is a key feature of stock steel grating. It allows the product to be tailored to meet specific needs and requirements. Different types of stock steel grating are available in different sizes, shapes, and configurations. This includes load bars, cross bars, and panel layout.

High Load-Bearing Capacity

High load-bearing capacity is a key feature of stock steel grating. It is important for applications that involve heavy traffic or loads. Stock steel grating is manufactured with high-quality steel. This enhances its strength, rigidity, and structural integrity.

Safety and Slip Resistance

Safety and slip resistance are key features of stock steel grating. It makes it a preferred choice for walkways and industrial applications. Steel grating has a series of horizontal and vertical bars.

Lightweight and Easy to Handle

The stock steel grating is lightweight. This makes it easy to handle and transport. Despite being lightweight, it still offers high strength and load-bearing capacity. This makes installations easier and more cost-effective.

There are multiple scenarios where steel grating can be utilized in different applications and industries.

Walkways and Pedestrian Paths:

Steel grating walkways allow for high foot traffic. They are used in industrial and commercial areas and are used in parks and recreational areas.

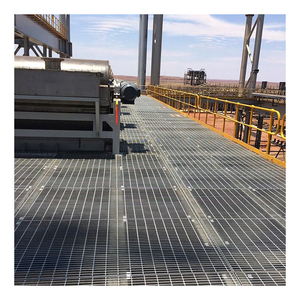

Platforms and Catwalks:

Stock steel grating catwalks and platforms are used in industrial areas. They provide a safe working environment for workers. They are also used in oil rigs, power plants and manufacturing sites.

Stair Treads:

Steel stock grating is used on stairs in industrial areas. They provide traction and reduce slippery surfaces. They are also used in commercial buildings and public spaces.

Machine and Equipment Grilles:

These grilles are used in various machines and equipment. They allow for light and air to pass through. They also prevent debris from entering and assist in weight reduction.

Drainage Covers:

Steel grating drainage covers are used in urban areas. They allow water to drain quickly and prevent flooding during heavy rainfall. They are also used in parking lots and driveways.

Building Facades:

Stock steel gratings are used on building exteriors. They provide a modern look and allow air circulation. They are also used in sunshades and brise-soleils.

Bridges and Crossings:

Steel grating bridges are used in pedestrian and vehicular crossings. They are used in temporary and permanent installations. They are also used in agriculture and forestry.

Electrical and HVAC Applications:

Steel gratings are used in electrical and HVAC systems. They support ducts, cables and ventilation units. They are also used in fire escapes and emergency exits.

Aisles and Storage Areas:

Stock steel grating allows for easy movement of forklifts and pallets. They enhance visibility and airflow in storage areas. They are also used in warehouses and supermarkets.

Clean Rooms and Laboratories:

Steel grating is used in clean rooms and labs. They allow for easy cleaning and maintenance. They also support sterile environments and scientific experiments.

When choosing a steel grating stock for sale, there are several factors that wholesalers and retailers should consider. They include:

Durability

Check the durability of the stock steel grating. Every steel grating has a different load capacity depending on the type and application. The load capacity indicates how durable the grating is. Also, check the spans and spacing of the steel stock grating. Spans are the distance between the supports, while spacing is the center-to-center distance between the steel bars. The more support bars there are, the more durable the steel grating is.

Corrosion resistance

All stock steel grating is exposed to harsh environmental conditions that can cause corrosion. Therefore, it is important to get a grating that is galvanized or coated to prevent rust. When choosing a stock steel grating, check the type of coating and galvanization it has. For example, hot-dip galvanized steel grating offers better rust protection than standard galvanized grating.

Quality and standards

Wholesalers should get stock steel grating that meets international quality standards. This will ensure maximum safety for their customers. The steel grating should also be certified to guarantee quality.

Customer reviews

Before buying steel grating in bulk, it is important to check the reviews of previous customers. This will give the buyer an insight into the quality of the product and the experience of other clients when working with the manufacturer.

Consulting a Professional

Choosing the right stock steel grating can be challenging, especially for those new to it. Therefore, it is advisable to consult a professional who will help determine the right product to purchase based on the intended application.

Q1: How is non-slip steel grating fabricated?

A1: The steel bar grating is manufactured by welding or interlocking steel bars and crossbars. It can be coated or punched with non-slip finishes like serrated edges, coatings, or punched patterns.

Q2: How can one access or walk through the stock steel grating?

A2: Walkable areas or access points are created on load-bearing steel grids. The areas are spaced 4 inches apart and are non-slip and safe for walking. They can support the weight of personnel walking through.

Q3: What are the visual characteristics of stock steel grating?

A3: Stock steel grating has a grid-like pattern with vertical load-bearing bars and horizontal crossbars. It offers a see-through design and is available in various spacing options.

Q4: What's the aesthetic appeal of stock steel grating?

A4: The aesthetic appeal of stock steel grating is minimal due to its utilitarian design for strength, safety, and durability. However, it provides a modern industrial look and can be finished for visual enhancement.

Q5: How is steel grating installed?

A5: Installation involves placing the steel grating on support beams, securing it with bolts or clips, and ensuring it is level and stable. It requires proper alignment and spacing for safety and support.