(400 products available)

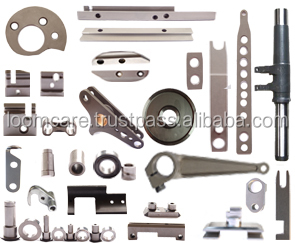

Sulzer loom spare parts include various types of components for the loom machine, which are critical for maintaining and repairing the loom machine. Here are some of them:

Weaving mechanism parts are the core components for the loom machine, including the shuttle, shuttle box, picker, etc. The shuttle is to carry the weft yarn through the shed to complete the weaving process. It is also the most important part of the weft insertion device. The shuttle box is an essential part of the shuttle loom. It provides the shuttle's path, reduces the friction of the shuttle, and coordinates the opening and closing of the shed. The picker is a mechanism for selecting and inserting the weft. It is also the most important weft picking device in a shuttleless loom.

Wear and tear parts are components that bear the brunt of the friction and movement during the weaving process. They need to be replaced regularly to ensure smooth operation and minimize downtime. Wear and tear parts include reeds and drop wires. The reed is a comb-like component that evenly spaces the warp threads and beats in the weft. It is also known as the beater. Drop wires are used to control the opening and closing of the shed, allowing the weft yarn to pass through and form the fabric. They are attached to the heald frames and move up and down with the movement of the loom.

The lubrication system is responsible for ensuring the smooth operation of the loom machine by providing lubrication to the moving parts. Its components include oil lines, pumps, filters, etc. They help to ensure that the parts that need lubrication are well-oiled to reduce friction and wear.

The electronic parts of the loom machine include sensors, controllers, wiring harnesses, etc. These components are the brain and nerves of the loom machine, responsible for controlling its operation and monitoring various parameters. For example, the sensor detects the position and movement of the components, while the controller processes this information and sends commands to drive the components.

Apart from the above, there are many other types of loom spare parts, such as the braking system, the let-off system, etc., all of which are critical components that play important roles in the loom machine.

Many sulzer loom spare parts have different specifications and require unique maintenance practices. Some of them include:

It is important to inspect the loom parts regularly. This will help in identifying any wear, damage, or signs of issues. Manufacturers recommend checking mating surfaces for signs of wear, corrosion, or scoring. Also, check moving parts for proper movement and clearances. Additionally, inspect seals and gaskets for any signs of leaks or deterioration. Regular inspections help in detecting potential issues early and addressing them promptly.

Proper cleaning is an important maintenance practice for loom parts. Cleaning is an effective way of removing dirt, debris, and contaminants that can cause wear or damage. When cleaning the parts, it is important to use the recommended cleaning products and methods. This is because some parts may require specific cleaning solvents or techniques. Also, manufacturers recommend avoiding harsh chemicals that may damage the parts. After cleaning, it is important to dry and lubricate the parts to prevent rust or corrosion. Regular cleaning helps in prolonging the lifespan of the loom parts.

Some loom parts require lubrication to reduce friction and wear. Lubrication helps in ensuring smooth operation and preventing premature failure. When lubricating the parts, it is important to use the suitable lubricants recommended by the manufacturer. Lubricate all moving parts such as bearings, gears, and slides. Although some parts do not require lubrication, it is important to follow the manufacturer's recommendations. Proper lubrication helps in improving performance and extending the life of the loom parts.

Proper storage is an important maintenance practice for loom parts that are not in use. Storing the parts properly helps in protecting them from damage and contamination. Manufacturers recommend storing the parts in a clean, dry, and well-ventilated area. Also, the parts should be kept away from corrosive chemicals or extreme temperatures. For fragile parts, they should be stored in protective cases or containers. Proper storage helps in preventing premature wear and damage.

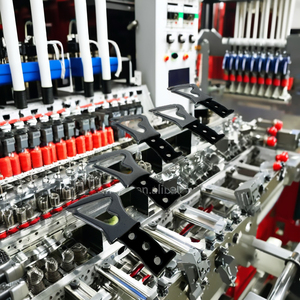

Sulzer looms are mainly used in the textile industry for weaving. The process involves interlacing two sets of yarn threads, which are usually made at right angles to each other. The main goal of weaving is to create a fabric. Depending on the design and the type of fabric required, different weaving techniques are used. Sulzer looms are capable of producing a wide range of textiles, from simple fabrics to complex ones. They can weave materials such as cotton, silk, wool, polyester, and other synthetic fibers, to name a few.

Sulzer looms are popular among businesses in the garment and home textiles industries. They are also used to produce technical textiles, carpets, and other heavy-duty, multiaxial materials. The looms have a rugged design to withstand the high tension and pressure required to weave such materials. Besides, Sulzer looms are also used in various research and development scenarios within the textile industry. This includes testing new materials, exploring innovative weaving techniques, and developing new fabric designs.

Some educational institutions with textile programs might also use Sulzer looms to train students. The looms are great for teaching students how to weave different types of textiles. Sulzer looms may also be used in the following scenarios:

Choosing the right spare parts for Sulzer looms is crucial for the efficient functioning of the machinery. Here are some factors to consider when selecting the looms' spares.

It is important to identify the loom's model and the part number of the spare required. The part number can be found in the loom's manual or on the part itself. Loom manufacturers provide a unique part number for each component.

It is important to opt for spare parts manufactured with quality materials. Sulzer loom parts made from quality materials are more durable and less likely to wear out. They also provide consistent performance and contribute to the overall efficiency of the loom.

Ensure that the selected spare part is compatible with the type and model of the Sulzer loom. Looms come in different varieties with distinct specifications. Each part may have variations depending on the type of loom. Confirm that the part number matches the loom model and specifications to avoid any malfunction.

It is essential to strike a balance between the cost and quality of the spare parts. Consider the budget while selecting the required parts. If purchasing an expensive part, make sure it is a crucial component of the loom. Opting for a more affordable option may be suitable for parts with less critical roles. Ensure that even those affordable parts are of acceptable quality.

It is important to ensure that the spare parts purchased for the Sulzer loom are genuine. The parts should come from an authorized distributor. Genuine parts are more likely to offer warranty coverage and ensure the loom's performance. The warranty provides protection in case the part fails prematurely. It also offers peace of mind and a guarantee of quality.

Q&A

Q1: What are the main Sulzer loom parts?

A1: The main parts of the Sulzer loom are the reed, shuttle, heddles, and the frame. The reed is responsible for pushing the weft thread into the warp, where the weft thread is inserted. The shuttle carries the weft thread and moves through the gap in the warp. The heddles are used to control the warp threads, while the frame is the loom's supporting structure.

Q2: Are Sulzer looms still made?

A2: The Sulzer loom company still exists, but it has transitioned to making other types of machinery, such as pumps and equipment for the chemical processing industry. The Sulzer loom is still made in some parts of the world, but the company has diversified its product line.

Q3: Do modern looms use compressed air?

A3: Modern looms use a variety of power sources, but most modern Sulzer looms use compressed air to power the weft insertion mechanism.