(50 products available)

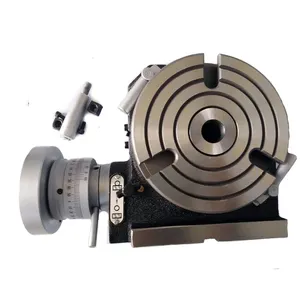

Machinery parts like the TSL200 Rotary Table come in a variety of forms to accommodate a wide range of applications in machining centers and the manufacturing industry. Some of these types are as follows:

Manufacturing Rotary Tables

The TSL200 manufacturing rotary tables are typically used for high-precision tasks like CNC milling and machining. These tables allow as many axis movements to be made as necessary by rotating the workpiece set on the table, which reduces the need for repositioning. The TSL200 rotary table is a 4-axis CNC rotary table with an automatic indexing system that permits precise and repeated angles of workpiece positioning.

Vertical Rotary Tables

An (TSL)200 vertical rotary table like the TSL200 is similar to an above-discussion horizontal type but with a vertical table setup. An upright shaft is used to mount discs and fixtures in an enclosed housing. The gear driver and indexer are top-mounted. This rotary table is preferred for using fixtures with gravity to simplify work setups and increase safety. Like its horizontal counterpart, it can have many different versions, including transmission type, worm gear, or electronic drive.

Worm Drive Rotary Tables

A worm drive rotary table like the TSL200 worm drive rotary table has a worm and wheel assembly for its indexer. Due to its low-cost motorization and simplicity, it is commonly used in the cinematic universe and museums for wide and slow use and scale. In high-torque situations, it can apply a large and equitable ratio to ease and disperse the level of torque.

TS200LSL Rotary Tables

A late model of the TSL200 rotary table is the TSL200 LSL, which contains many of the above features but offers an electrospindle for self-directing completion and high precision. This spindle makes the table more flexible as it can fulfill several jobs without changing its setup or workpiece position.

The TSL200 rotary table's specifications may vary based on its model and application, but some key specifications are constant that indicate capability and features.

A rotary table is a costly investment, and it's essential to conduct regular maintenance to get the most out of it. Doing this will keep the machine performing excellently and assure its longevity.

Before any maintenance practice, disconnect the machine from power, and do clearing to remove dust and debris. Then, do this routine maintenance:

The TSL200 rotary table is used in the drilling industry for numerous applications. Some of them are as follows:

When selecting the TSL200 rotary table, several factors must be considered to find a suitable matching one for specific needs.

Size and load capacity

Firstly, size and load capacity are important. It is crucial to determine the dimensions and weight prior to selecting a rotary table machining center. Make sure the rotary table can fit the workpiece and fixture, and ensure its load capacity can handle the rotary table weight.

Accuracy and precision

Secondly, accuracy and precision are vital issues when selecting the rotary table. Buyers need to choose a table with the required accuracy and precision according to specific applications and tasks. Generally, tables with higher accuracy and precision are more expensive.

Drive system

Thirdly, it is crucial to consider the drive system of the rotary table. Different machining tasks may require distinct drive systems, such as servo motor drives, stepper motor drives, hydraulic drives, etc. Choosing a suitable drive system can ensure the table's proper functioning and control during use.

Control methods

Moreover, buyers may consider the control methods available for the rotary table, such as manual control, CNC control, etc. Selecting a table that corresponds with the required control method can facilitate task accomplishment more efficiently and conveniently.

Quality and brand

Additionally, the quality and brand of the rotary table are significant factors in selection. Choosing a reputable brand with good quality can help ensure the table's performance and durability during use.

Price

Finally, buyers can select a suitable TSL200 rotary table after considering various factors, such as the quality, brand, and other aspects that have an impact on the price. Choose a rotary table that offers good cost performance to meet business requirements.

Q1: What industry uses rotary tables?

A1: The rotary table is critical in manufacturing and machining industries. In manufacturing, this device helps to produce high-quality shapes, reduce waste, and boost productivity.

Q2: Does a rotary table have an attachment?

A2: Yes, the rotary table has attachments for specific operations. Some accessories are the index head, dividing head, tailstock, and holding fixtures. All these attachments enhance the versatility of a rotary table.

Q3: How does a rotary table work?

A3: The rotary table moves workpieces on its table at preset angles with the help of an index system. The operator first mounts the workpiece onto the table. Then, he sets the desired angle on the index head. Next, he starts the device, and the workpiece moves to the preset angle. The procedure repeats itself. This method is simple and efficient for machining processes like milling and drilling.

Q4: What are the different types of rotary tables?

A4: Rotary tables come in various types. The most common ones are the traditional rotary table, the tilting rotary table, the super table, and the digital rotary table. Each kind has its own characteristics and works with particular kinds of machines.