(355 products available)

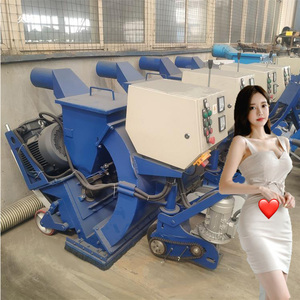

The turntable shot blasting machine is a type of shot blasting machine with a circular platform for holding workpieces and helps improve the productivity and perform the uniform operation of the machine. Based on the loading method of the blasting room, turntable shot blasting machines are usually divided into the following categories:

Common Turntable Shot Blasting Machine

The common turntable shot blasting machines have a turntable that facilitates loading and unloading of workpieces. The workpieces are placed on the turntable, which is then rotated to expose different areas of the workpiece to the blasting stream. The operator can step away from their station to prepare the next workpiece for blasting, which helps to reduce machine downtime and increase productivity. Common turntable shot blasting machines are typically used for workpieces that need to be blasted on multiple surfaces but do not have complex shapes.

Power Automatic Turntable Shot Blasting Machine

Pew automatic common turntable shot blasting machines are powered to rotate by a motor or other power sources. This allows for a more consistent and uniform exposure of the workpiece to the blasting stream. Additionally, it frees up operator hands to prepare other workpieces, which can further increase productivity. Power automatic turntable shot blasting machines are typically used for operations requiring high consistency and efficiency.

Feeding Automatic Turntable Shot Blasting Machine

Feeding automatic turntable shot blasting machines have an automatic feeding system that continuously feeds workpieces into the machine for blasting. This eliminates the need for interruption in the blasting process and allows for a continuous operation, thereby increasing productivity and efficiency further. Feeding automatic turntable shot blasting machines are suitable for high-volume production lines where large quantities of workpieces need to be blasted continuously.

Robot Automatic Turntable Shot Blasting Machine

Robot automatic turntable shot blasting machines are equipped with a robot that provides an automated blasting solution. The robot can be programmed to blast workpieces with different sizes and shapes, and it can also be programmed to blast with varying intensities and patterns. This allows for greater flexibility and precision in the blasting process. Robot automatic turntable shot blasting machines are typically used for more complex and customized blasting applications.

The specifications of a turntable shot blasting machine are as follows.

Maintenance of a turntable shot blasting machine is crucial to keep it in good shape and operating well. Here's a brief maintenance guide:

The turntable shot blasting machine has different application scenarios depending on the industry. It is widely used in the following industries:

When purchasing a turntable shot blasting machine for sale, buyers should get the following details.

Determine the source of the turntable:

Around the world, many manufacturers produce blast turntables. Purchasing from a local manufacturer will save on shipping costs, while purchasing from an overseas supplier may lead to greater discounts because of the good resale value for clients. Investigate the suitable countries for buying to ensure sufficient stock.

Assess the market's buying capacity:

When starting to sell the turntable shot blasting machine, buyers should investigate the market to ascertain its buying capacity. A small market may not need a larger stock, while a bigger market will require a more significant investment as most customers will demand the machine.

Understand the customers' needs:

The type of customers will determine the kind of machines to purchase. Industrial customers will require heavy-duty machines, while smaller workshops will look for smaller capacities and more minor spares to service their machines.

Negotiate pricing with suppliers:

Once a suitable supplier is found, buyers should compare prices with other suppliers and negotiate to get the best price. Consider the minimum order quantity when bargaining. Try to get discounts when ordering a more substantial quantity.

Understand the shipping process:

It is good to work with a reputable shipping company that delivers goods on time and in a safe condition. Buyers should provide the correct shipping documents and details about the turntable shot blasting machine so that there are no delays at customs.

Provide after-sales service:

People will be more confident to purchase a product if they know that there is after-sales service in the event of a problem. Buyers should familiarize themselves with the machines so they can offer repair services or replace defective parts.

Q1: What is the difference between a turntable shot blasting machine and a carousel shot blasting machine?

A1: The functioning principle of the two machines is similar. They both use the revolving motion of the workpiece to expose all parts of the workpiece to the blasting path. However, the way to present the workpieces is different. A turntable presents the workpieces in a horizontal plane, while a carousel presents them in a vertical plane.

Q2: What are the limit sizes of the workpieces that can be blasted in a turntable shot blasting machine?

A2: The limit size of the workpiece will be determined by the dimension of the blasting chamber and the turntable itself. The height and diameter of the turntable can be customized accordingly to suit the size of the workpiece that needs to be blasted.

Q3: Can more than one workpiece be blasted at the same time in a turntable shot blasting machine?

A3: It is possible to blast more than one workpiece at the same time if they are of small enough sizes to be accommodated in the turntable. The turntable could then be fitted with multiple fixtures to hold the workpieces in place during blasting.