(8112 products available)

As underground pipelines infrastructure has been expanded and improved to help meet the increasing demands of industries and consumers, several types of underground pipelines are frequently used in urban areas.

Gas pipeline

Gas pipelines are usually placed under the ground and controlled to supply residential and commercial users with natural gas. The pipeline may be made up of steel or polymer. According to the specifications for urban natural gas pipelines set forth by relevant departments, underground gas pipelines must be marked above ground in addition to being located well beneath the ground so as to guarantee that various operators can locate and use them securely.

Water pipeline

In order to distribute clean water to households and industries, water pipelines are laid beneath the earth. To stop pollution and guarantee water quality, they are often made of materials like high-density polyethylene (HDPE) or ductile iron (DI) and are located far from other underground pipelines. Except for regular maintenance and repair, water pipelines often go unnoticed since they are buried deep within the earth.

Heat Pipeline

Underground heat pipelines transport thermal energy from central heating sources, such as power plants or thermal stations, to end users. Heat pipelines are usually insulated, composite, and steel-pipeline-made to lessen heat loss. Urban heat pipelines play a key role in centralized heating systems during winter in cities.

Oil pipeline

Oil pipelines are used to transport crude oil or refined petroleum products from production areas to refineries or distribution centers. They are typically made of seamless steel pipe or glass fiber reinforced plastic (GFRP) and buried deep underground in the suburbs or countryside.

Telecommunication conduit

Telecommunication conduits provide protective pathways for telecommunication cables, such as fiber optic cables or copper cables. These underground pipelines ensure the stability and security of telecommunication networks. They are often made of high-density polyethylene (HDPE) and are laid along roads or in public easements.

Underground pipelines are the most critical part of a distribution system. Specifications may differ depending on the product, application, and materials.

Dimensions

Underground pipelines come in various lengths and diameters. The size depends upon the job needs and the type of material being used. For example, large underground gas pipelines will naturally be bigger than small water service lines.

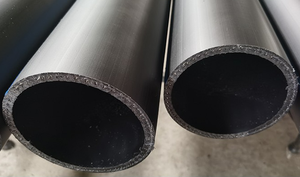

Materials used

The underground pipeline is made up of several materials to ensure great functionality and long-lasting.

Joining techniques

The joining techniques will vary according to the material of the pipeline. However, commonly used methods include socket fusion, butt fusion, electrofusion, etc.

Pipelines Dimensions

Depending on the usage, underground pipelines will be buried at various depths. In case of difficulties in locating or accessing the line, greater depths are usually necessary for larger pipelines to avoid conflicts with other established utilities.

Generally, the depth of small diameter pipelines is around 36 inches to the top of the pipe. The depth may vary according to the climate, geotechnical and soil conditions, and local rules and regulations.

Ratings

Pressure Rating: Underground pipelines are rated according to the pressure they can handle. This is especially important for high-pressure gas and water lines. Underground pipeline suppliers ensure that the pipeline is manufactured according to the applicable standards and regulations. For example, the ISO 3183 covers the specification for the design, materials, and testing of pipelines used for the transportation of oil and gas in offshore and onshore environments.

Proper underground pipeline systems maintenance is vital for the longevity and efficiency of the system. Regular inspections, leak detection, and prompt repairs, along with proper handling and storage of pipeline materials during installation, can go a long way in ensuring a long life for the pipeline system. Following all local codes and regulations is imperative.

Underground pipelines are used in various industries. Here are some of the key uses of underground pipelines:

Oil and gas transmission

Underground pipelines play a critical role in the transportation of crude oil and natural gas from production areas to refineries, processing facilities, distribution centers, and end-users. They ensure the efficient and secure conveyance of these energy resources, facilitating the functioning of numerous industries and daily life.

Water supply and distribution

Underground pipelines are the conduits for water supply and distribution systems, ensuring a reliable flow of clean drinking water to households, businesses, and institutions. They support urban development, public health, and economic activities by providing the essential resource of water.

Sewage and waste water management

Underground pipelines are the backbone of sewage and wastewater management systems, collecting and transporting municipal and industrial waste for treatment and disposal. They play a vital role in protecting public health and the environment by preventing pollution and maintaining effective sanitation.

Telecommunications and utility networks

Underground pipelines protect and facilitate the operation of telecommunications and utility networks, including fiber optic cables, electric lines, gas distribution, and other essential services. They provide secure pathways for the infrastructure that enables communication, connectivity, and the functioning of various technological systems.

Transportation of other fluids and materials

Underground pipelines serve as versatile conduits for transporting various fluids and materials beyond oil, gas, water, and waste. They accommodate the movement of chemicals, beverages, food products, pharmaceuticals, and other specialized substances, playing a crucial role in industrial processes, supply chains, and logistics.

Selection of underground pipelines can be a daunting task, as it calls for several factors and an understanding of the distinct requirements of the industrial buyer's infrastructure.

Needs Analysis:

The first step is to know the requirements. This step involves understanding the purpose of the pipeline, the medium (water, oil, gas, etc.), the pressure level, temperature, and soil conditions. Terrain analysis is also a part of this. Buyers must consider factors like depth, stability, and moisture content of the soil. The infrastructure can determine the distance and diameter needed for the pipeline. Hence, the business buyer must consider all these factors before moving to the next step of choosing an underground pipeline.

Materials:

Once the needs are analyzed, it is easier to choose the material. Different materials have their advantages and disadvantages, so industrial buyers need to choose those that fulfill their needs perfectly. For instance, if chemical resistance is needed, then plastic (like PVC, HDPE) is a better choice. If a high-strength material is needed for the pipeline, buyers will have to choose ductile iron. Though the later option is expensive, it will fulfill the need perfectly.

Compatibility with Medium:

It is crucial to choose a pipeline material that will handle the medium's pressure. For instance, if a pipeline has to carry high-pressure gas, a material like stainless steel or high-density polyethylene (HDPE). This way, underground pipelines will function effectively.

Environmental Compliance:

In this step, buyers have to ensure that the materials and manufacturing processes comply with environmental regulations. They must check the emission impact and carry out a proper analysis before investing their money into a product.

Cost-Benefit Analysis:

In the end, it is crucial to carry out a cost-benefit analysis and calculate the long-term expenses. Include the installation, maintenance, and potential lifespan of the pipelines, and after doing all these calculations, choose the pipelines that will work well with the entire infrastructure.

Q1: What are the factors to consider when choosing materials for underground pipelines?

A1: Consider the transport medium, pressure and temperature, soil conditions, cost, risks, longevity, and leaks.

Q2: What are the construction methods for underground pipelines?

A2: There are trenching, directional boring, and trenchless pipeline replacement.

Q3: What are the maintenance and monitoring methods for underground pipelines?

A3: Regular maintenance includes periodic inspections, leak detection, and monitoring system installation.

Q4: What are the trends in underground pipeline technology?

A4: The trend is towards smart pipeline systems with monitoring capabilities, sustainable materials, and efficient construction techniques.