(403 products available)

Used clay extruders are available in various types, each with unique features and benefits.

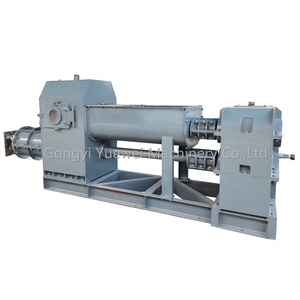

Industrial clay extruder

This is widely used in big factories. It is perfect for high-extrusion-volume needs. It can work for a long time without stopping. An industrial clay has a powerful motor, a big barrel, and strong materials. So it works well and lasts a long time with little maintenance. An industrial clay extruder is great for making clay in large amounts.

Screw clay extruder

The screw clay extruder is one popular option among many available. It pushes the clay out using a screw mechanism. A screw works by rotating and moving materials forward. The screw in this extruder shapes and pushes clay into various forms. Many prefer the screw design because it offers consistent clay output. The uniformity is great for projects that require evenness. The reliable operation meets the needs of different users well.

Hydraulic clay extruder

A hydraulic clay extruder uses hydraulics to push out clay. This contrasts with other types that rely on a motor or gear. The hydraulic system works by moving liquids. It creates the force needed to push clay through the nozzle. Accordingly, this type gives users more control over how much and fast the clay comes out. The control is important for tasks requiring precise results. A hydraulic clay extruder can also handle thicker materials compared to others.

Pneumatic clay extruder

The Pneumatic clay extruder uses air pressure to push out clay. It is different from other extruders that use motors or hydraulic systems. The air pushes and moves the clay through a special opening or nozzle. Pneumatic extruders can be made to fit a range of air pressures. This allows users to have better control over the clay's speed and volume. This control is useful for jobs that need to be done precisely. Pneumatic extruders are also good for working with tough materials.

Generally, the specifications of an industrial clay extruder will vary greatly depending on the specific type and the model being manufactured. However, the following are some general key specifications.

Pressure

Some clay extruders will produce some representative crushing pressure that will be sufficient to shape the clay into the desired profile. This pressure is usually measured in pounds per square inch (PSI).

Length

Some clay extruders will have a barrel length that will determine the length and size of the clay that can be pushed through the nozzle. Longer barrels extruders allow longer shapes to be made.

Diameter

The diameter of a clay extruder barrel determines the thickness of the clay shape that can be created. Clay that has large diameter barrels is often used for pottery.

Material

An air conditioner that helps in dehumidifying rooms, commercial spaces, and other indoor areas knows no season; summer or winter, the appliance comes in handy, and this means that it stands to be one of the most used household gadgets. Especially in America, a lot of emphasis on cooling systems meaning that air conditioners are in most homes. The more we use an air conditioner, the bigger the burden on it, and this often causes a great deal of wear and tear. Sometimes, it can be so severe that the requirement of AC repair can almost be the same as that of the need for AC servicing. The following article will briefly delve into the difference between air conditioning repair and air conditioning servicing. See more about air conditioning servicing and how it differs from air conditioning repair.

An air conditioner that helps in dehumidifying rooms, commercial spaces, and other indoor areas knows no season; summer or winter, the appliance comes in handy, and this means that it stands to be one of the most used household gadgets. Especially in America, a lot of emphasis on cooling systems meaning that air conditioners are in most homes. The more we use an air conditioner, the bigger the burden on it, and this often causes a great deal of wear and tear. Sometimes, it can be so severe that the requirement of AC repair can almost be the same as that of the need for AC servicing. The more we use an air conditioner, the bigger the burden on it, and and this often causes a great deal of wear and tear.

In the case of hydraulic clay extruder machine maintenance, users are advised to create a regular maintenance schedule. To properly clean and maintain the machine, they should develop a routine of cleaning and lubricating it. Applying a release agent or lubrication on the edges and on the extrusion piston's face is part of the maintenance routine. After every use, operators should thoroughly clean the used clay extruder parts.

Hydraulic clay extruders are high production streamlines with low costs and no downtime. They require less maintenance than those volatile mechanical parts. Nevertheless, appropriate hydraulic cylinder oil must be used according to the manufacturer's specifications.

Used clay extruders have several pottery-making applications. Because of the versatility of clay extruder machines, they cater to various styles and preferences. Below are how pottery artists use clay extruders.

When buying used clay extruders for sale, buyers should consider the following tips to ensure the right choice for their ceramic studio.

Pay attention to the condition of the clay extrusion machine:

Check if there are any part damages or functional issues in the used clay extruder. Buyers should inspect the condition of the clay pushing cylinder and pug to ensure there are no leaks or clogs. The mechanism, components, and seals of the clay cutter should also be thoroughly assessed for wear and tear. Moreover, check if the motor and associated cables of the used clay extrusion machine are functioning properly. Overall, the entire performance of the used clay extruder should be reviewed cautiously to prevent any future risks of failure.

Assess the purpose of the clay extruder:

Before purchasing the used clay extrusion machine, buyers should determine the requirements of their ceramic studio. If the goal is to achieve complex shapes and profiles, consider getting an auger clay extruder. For simple shapes, a hydraulic clay extruder will suffice. Furthermore, if the ceramic studio needs to work with large volumes of clay, getting a larger-sized used clay extruder would be more appropriate.

Match the compatibility with clay type:

Often, a used clay extruder will be better suited for a specific type of clay. For instance, an electric-powered extruder would be ideal for oily and soft clay, while a hand-cranked extruder would be better for harder clay. To prevent any functional issues, buyers should get a used clay extruder compatible with the specific type of clay in their ceramic studio.

Consider development potential:

If there is potential for future development in the ceramic studio, it may be better to invest in an entirely new clay extruder instead of purchasing a used one. In some cases, a new machine may have equal or less cost than a used one. Therefore, buyers should analyze the situation before investing in a used clay extruder machine.

Q1: Who invented the clay extruder?

A1: James McBain invented the clay extruder in 1871.

Q2: How are clay extruders powered?

A2: Clay extruders can be powered by hand, hydraulic pressure, or electric motors. Hydraulic and electric extruders are more common in pottery workshops compared to manual ones.

Q3: What are the latest trends in clay extruders?

A3: The trend is moving more towards electrical extruders because of the ease of use without much manual effort. Many pottery workshops now prefer clay extruders with motorized and automated parts.

Q4: What is the difference between a ram and an automatic clay extruder?

A4: A ram extruder requires to be loaded with clay every time it is pushed forward. In comparison, automatic or driven extruders can continuously push out clay when the motor or driver is activated.