(311 products available)

Several types of Vamatex looms spare parts are available, each designed to play a specific role in the effective operation, maintenance, and repair of weaving machines. Most loom spare parts fall into the following categories:

Weaving Accessories

Weaving accessories are specialized kits and gadgets used to enhance the primary functionality of the loom. They do not form an integral part of the loom, but weaving requires them to work better. These include extra shuttles, weaving swords, pickers, bobbins, and beaters. For instance, to prevent the thread from tangling after it has been wound around the warp beam, it must first be placed around the loom shuttle, which is an example of a weaving shuttle.

Operational Components

Operational components are parts of the loom that facilitate movement crucial for the weaving process. They include the heddles, shafts, treadles, reeds, warp beams, and cloth falls. Typically, loom weavers pass the warp threads through the heddles. The heddles are then attached to the heddle shafts, which the user raises and lowers through the treadles. The movements create an opening (shed) in which the shuttle carrying the filling thread passes to form fabric. The pattern created during weaving determines the type of cloth fall one will use.

Textile Elements

These refer to threads or fibers integral to the loom that bear the brunt of the stretching and tension during the weaving process. They include reed, warp, and weft. The textile elements are usually mounted on the looms beams. The warp threads are longitudinally mounted on the loom beam, while the weft threads are horizontally positioned on the shuttle beam. The reed is mounted on the heddle shafts and is used to push the newly formed fabric across the loom.

Replacement Parts

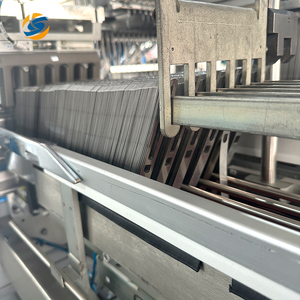

These include damaged components of the loom that need to be replaced to ensure the weaving process runs smoothly. They could be fabric cutting blades if they are damaged and need replacing, selvedge devices, electronic sensors, and circuit boards, to name a few.

Specifications of Vamatex looms spare parts vary depending on the nature of the spare part, the model of the loom, and its primary capabilities. Here are some examples of Vamatex loom spare part specifications:

Shuttles

Generally, shuttles have different lengths, measured in millimeters, to fit specific loom models. For instance, the shuttle length for Vamatex G39 models is approximately 301mm, while the length for the A22 model is around 171mm. Additionally, the shuttle width and weight are also critical dimensions. The width of the shuttle determines how well it carries the weft yarn as it traverses the warp yarn.

Picker

Pickers have a variety of specifications, including the materials used to make them, which have an impact on their endurance and effectiveness. The speed at which a picker can propel the shuttle depends on its size. A good picker should be able to maneuver the shuttle and insert the weft yarn at high speeds without causing interruptions to the weaving process.

Belts

Bets used in looms such as an 8 Vamatex loom come in different materials, including nylon and rubber. Their weight carrying capacity varies according to the tension and weights of strands/spools being used in the weaving process. The belt's capacity is also influenced by its length. For instance, a longer belt may have a lower weight carrying capacity compared to a shorter one.

Needles

Needles have many specifications, including gauge or shaft width, length, coating, and the materials used to manufacture them. In most cases, weaving needles are manufactured from high-carbon steel.

Maintenance of Vamatex loom parts ensures that the entire machine performs well. Additionally, proper care, cleaning and repair of parts increases the lifespan of the entire loom.

Regular Cleaning:

Regular cleaning of Vamatex loom spare parts is crucial for their long-term performance and upkeep. It hinders the build-up of lint, dust, and other debris that have the potential to impair the functionality of the spare parts. Cleaning can be done using soft brushes, vacuum cleaners, or lint rollers, which allow for the safe and effective removal of any form of contaminants that gather within or on the loom's spare parts.

Lubrication:

Lubrication maintains the efficiency and smoothness of moving components in the Vamatex loom, such as the shuttles and pickers. Lubrication minimizes the wear and tear of moving parts and reduces any form of resistance or friction that has the potential to slow down the weaving process.

Vamatex looms spare parts are used in various textiles and fabrics industry sectors, ranging from the fashion industry to home decor and automotive sectors.

These are a few examples of different uses for Vamatex loom spare parts. Vamatex looms have a distinct and essential role in the creation of textiles and fabrics in particular industries and are particularly necessary for specialized weaves.

Picking the correct Vamatex looms spare parts requires careful thought of the most important features, such as quality, compatibility, availability, etc.

Quality

The performance and lifespan of the weaving machine will be greatly affected by the quality of the spare parts. Poor-quality Vamatex loom parts can result in frequent breakdowns, costly repairs, and inefficient production.

Compatibility

Spare parts should be Vamatex-specific, as exact fit and optimal function are necessary for them to work better and smoothly with the weaving machine. Compatibility enhances efficiency, minimizes wear and tear, and prolongs the machine's lifespan.

Availability

It is necessary to consider the availability of Vamatex loom spares, as it ensures rapid repair and minimizes downtime. Frequent unavailability may lead to prolonged machine idle time, production inefficiency, and increased operational costs.

Pricing

A good balance between performance and cost needs to be sought so that an informed choice can be made without compromising the loom's efficiency and functionality.

Reliability of supplier

The looms' performance will depend on the quality of the spare parts supplied, and choosing a reliable supplier ensures the authenticity, quality, and performance of the spare parts.

Ease of installation

For smooth functioning, it is necessary for the spare parts to fit appropriately, work well together and be easy to set up, as this can reduce the costs of maintenance and repairs and can, therefore, be beneficial to their users.

Long-term performance

Frequent repairs can be avoided if long-lasting, robust, and dependable Vamatex loom spares are selected, as this will contribute to the overall efficiency and productivity of the business.

Q1: What material is used to make textile loom spare parts?

A1: Generally, the material used to manufacture loom parts varies depending on the specific component. However, most parts have metal as the primary material. In a Vamatex loom, for instance, aluminum and stainless steel are probably the most used metals. Aluminum is corrosion-resistant and light, which makes it ideal for components like reeds and frames. Stainless steel, on the other hand, is known for its strength, durability, and resistance to rust. Steel parts in a loom may include shuttles and cut-offs.

Q2: Are all loom spare parts compatibles with any loom?

A2: No, most loom spare parts are incompatible with any loom. They are designed to fit a specific type of loom, so trying to fit them into another may not work.

Q3: What are some signs that a loom requires new spare parts?

A3: Worn out damage is perhaps the most obvious sign that the loom needs new spare parts. One may also notice inconsistent weaving, which makes the fabric look irregular and uneven. A loud noise coming from the loom is yet another sign that most people fail to recognize. The noise could be a sign of mechanical issues or damaged parts.

Q4: How long do loom spare parts last?

A4: Generally, the lifespan of loom spare parts varies depending on several factors. These may include the specific part in question, the quality of the part, the intensity of usage, and the level of maintenance. Nonetheless, most premium quality loom spare parts can last several years if they are well maintained.