(3291 products available)

A water tank welder is used for welding tanks for storing water or other liquids. Bulk sellers can get different types of high-quality water tank welders from suppliers on Cooig. The list below includes the most common tank welders.

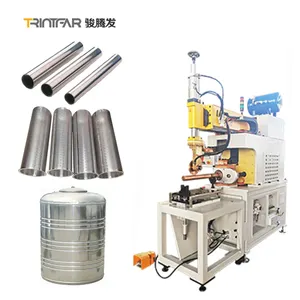

Water tank pipe welding machine

The water tank pipe welding machine is suitable for welding different pipes used in water tanks. It usually comes with two clamp blocks that hold the pipe fittings securely. The machine can weld vertical, horizontal, and circular pipes.

Portable water tank welding machine

This lightweight machine allows users to tank weld on-site or anywhere without restrictions. It is easy to carry and sometimes has handles for additional maneuverability.

Hydraulic water tank welding machine

The hydraulic welding tank welder uses hydraulic power to weld different tank shapes and sizes. It is preferable for camping, rural areas, or situations where there is no electricity.

Manual water tank welding machine

This machine requires users to manually control the device to ensure an even or consistent weld. Even though this welder needs more input, it is more affordable than other tank welders.

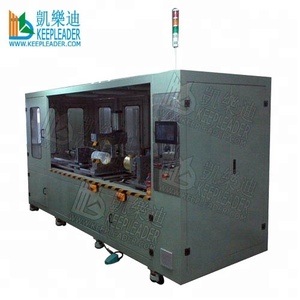

Automatic water tank welding machine

The automatic tank welder allows for automatic welding without manual operation. This type of welding gives a uniform, quality tank weld every time. However, it can be more expensive than manual welding machines.

Water tank TIG welder

These welders use tungsten as an electrode to perform precise or high-heat welds without splatter. They are ideal for smaller water tanks or those requiring more delicate welds. However, this type of tank welder is not suitable for welding larger tanks due to its low welding speed.

Water tank MIG welder

The MIG welder uses metal to make welds quickly and efficiently. The advantage of the MIG water tank welder is that it is more comfortable in various positions without needing shielding gas. This ability makes it an ideal choice for welding large tanks.

Water tank stick welder

This is the most common welder for water tanks because it uses an electrode-covered stick to make the weld. It is suitable for welding unevenly cleaned or oxidized surfaces.

Below are some common use cases of water tank welders:

Industry

Most industries use water tank welders. They weld large tanks that store lots of water. They also make really big tanks that can take in a lot of raw materials and products. They use these tanks in places like oil and gas corporate, food and drinks, and chemical manufacturing. The large vertical water tank welder is a major tool that helps us store lots of materials for production.

Storage Facilities

A storage facility is a place where lots of goods are usually stored. It can be at a warehouse, logistic center, or distribution hub. Storage tanks that hold products are usually made with tank welders. The products can be liquids like oil, chemicals, or even foods. It can also be beverages like milk and fruit juices. The storage tanks help with proper inventory management and product distribution.

Agriculture

The agriculture industry uses water tank welders to store water, fertilizers, feed, and other farm products and materials. Farm owners can easily supply, store, and maintain farm products with these tanks. They also help agricultural industries efficiently manage their farm resources.

Municipal Water Systems

The municipal water systems refer to welders used in public and local government water tank systems. These systems are in charge of properly storing and distributing potable water for residents and businesses to use. The tanks are typically heavily used, so they have to be durable and made with strong and quality materials. Tank welders weld the tanks and ensure they can take in large volumes of water and won't easily break or leak.

A good water tank welder must meet several essential features. These can be used as features of the water tank welder that need to be purchased or considered to ensure compliance with the use requirements of the water tank.

Q1: What is a water tank welder used for?

A1: A water tank welder is used to weld together the panels of a water tank to create a strong, durable, and leak-proof joint. These are often used to create large storage tanks for drinking water, rainwater, and other industrial liquids.

Q2: What are the different types of water tanks?

A2: There are different types of water tanks including overhead tanks, underground tanks, and sectional tanks. Different types of water tanks require different types of welding apart from conventional water tank welders. For example, the curved structure of an overhead tank may require an automatic circumferential welder with a carriage, while a sectional tank may require a multi-head welder for flat-to-flat welds.

Q3: What materials are water tanks commonly made of?

A3: The two most common materials for water tanks are stainless steel and mild carbon steel. Depending on the material being used, different types of welding machines will be required.

Q4: How is the size of a water tank determined?

A4: The size of the water tank is determined based on factors such as the purpose of the tank, available space, water consumption, frequency of supply, and demand fluctuation. Note that larger water tanks may require more welding time and equipment.