(5966 products available)

Fiberboard is a type of engineered product made from wood fibers, which is used in construction and other industries. It is a popular choice among manufacturers due to its versatility, cost-effectiveness, and ease of use. There are different types of white fiberboard, and each type has its specific use. The types include:

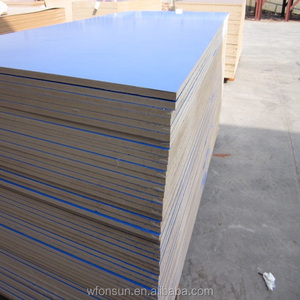

Fiberboard is a panel building material made from wood fibers bonded together by heat, pressure, and adhesives. It is usually made from leftover wood chips from saw mills, making it an eco-friendly choice for contractors. White fiberboard is used extensively as an engineering material in construction because of its versatility, strength, and low weight. Fiberboard is used for:

Fiberboard has many features that make it a popular choice among contractors. These include:

Architectural Applications:

Fiberboards are widely used in interior design because of their smooth surface and painting capability. They are used as wall panels in commercial and residential spaces. This creates a seamless and customized design. They are also used as ceiling tiles. These fiberboards reduce the echo in spaces with high ceilings. Also, the white color of the fiberboard tiles reflects light and improves the overall brightness of the space. Fiberboard is also used in partitions. The smooth surface and the ability to customize the design with prints make these fiberboards a good option for interior walls and partitions.

Furniture and Cabinetry:

White fiberboard is a common material in the production of cabinets. It is used to create the frame and the body of the cabinet. This is because it is less expensive than wood. It is also easy to machine. Fiberboards are also used to make the back panel of cabinets. The edge banding can be applied to match the panel with the rest of the cabinet. White fiberboard is also used to construct drawers. The smooth surface of the fiberboard ensures that drawers open and close easily.

Doors:

White fiberboard is a common material for internal doors. The core of the door is made of fiberboard, which adds weight to the door and improves its strength. The surface layer is also made of fiberboard. It can be finished with paint, wood veneer, or other surface materials to create a door design that matches the interior design.

Sound Studios:

Acoustic panels: Fiberboards with high-density structures are used to make acoustic panels. These panels are mounted on walls and ceilings. They absorb sound waves and reduce echoes in sound studios. The smooth fiberboard surface can also be printed with patterns. This adds visual interest to the sound studio while still minimizing sound echoes. Fiberboard is also used to make bass traps. These are high-density fiberboard structures that trap low-frequency sounds. They are placed in the corners of the sound studio.

When choosing a white fiberboard to stock, business owners should consider the following factors:

Board type

As discussed above, there are two main types of boards, MDF and HDF. The use of the board will determine the type a buyer needs to get. Boards used for furniture will require MDF, while HDF is suitable for wall paneling.

Thickness

Fiberboards come in different thicknesses. When buying, it is important to consider the load-bearing capacity and structural integrity of the board. Thicker boards are suitable for applications that require durability, while thinner boards are suitable for lightweight constructions.

White finish

White fiberboards are made to have different types of white finishes. Some have a glossy finish, while others have a flat or matte finish. Business owners should pay attention to the desired aesthetic of the end-use product when choosing a fiberboard.

Edge treatment

White fiberboards have raw edges. However, some boards feature beveled or square edges. Fiberboards with square edges are suitable for applications that require seamless joints, while those with beveled edges are used for decorative purposes.

Environmental certifications

Buyers should look for fiberboards with environmental certifications, such as CARB or EPA. These certifications show that the board complies with the regulations regarding formaldehyde emissions. It is an important factor for environmental-conscious customers.

Price

First-time buyers should consider the price of the fiberboard to ensure it is within their budget. However, it is important to note that a low-priced board does not mean it is of low quality. Buyers can find a board that fits their budget without compromising quality.

Q: What are the differences between white fiberboard and MDF?

A: The two boards are similar. However, the white fiberboard has a higher density than MDF. The fiberboard is also available in three types: high-density, medium-density, and low-density fiberboard. On the other hand, MDF comes in medium and high-density boards.

Q: Is white fiberboard waterproof?

A: The standard white fiberboard is not waterproof. It is susceptible to water damage. However, some boards have waterproof capabilities. These include white fiberboard with wax and engineered fiberboard.

Q: Does fiberboard contain glue?

A: Yes, the white fiberboard manufacturing process involves the use of adhesive glue. The fiber material is also glued to form the basis of the board. The glue used can be formaldehyde or no-formaldehyde glue.

Q: What are the disadvantages of white fiberboard?

The web search volume for the keyword "white fiberboard" in the Construction & Real Estate category shows a notable trend with an average monthly web search volume of 40. Over the past year, there has been a significant increase of 67%, even though the three-month change shows a stable 0%. The data over the last twelve months reveals fluctuating web search volumes, ranging from a low of 30 in December 2023 to highs of 50 in February, June, July, and November 2024.

Analyzing the monthly search data, "white fiberboard" experienced its peaks primarily during the spring and summer months, with notable highs in February, June, July, and November. Conversely, the lowest web search volume occurred in December 2023, suggesting a seasonal pattern where interest in this material increases during specific times of the year, likely aligned with construction cycles and real estate development phases.

The consistent yet fluctuating pattern in the web search volume for "white fiberboard" indicates a strong seasonal influence, with spikes during periods typically associated with increased construction activity. The year-long 67% increase in web searches, despite a stagnant recent trend, suggests growing interest or market changes that could be influencing the demand for this product in the construction and real estate sectors.