(2441 products available)

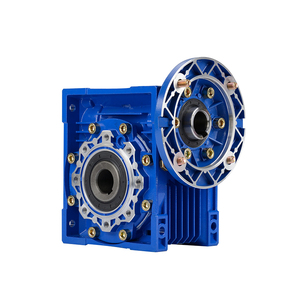

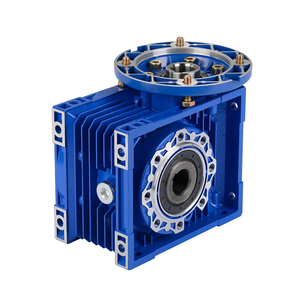

A worm gearbox hollow shaft is a type of gear mechanism that consists of a worm and a worm wheel. The worm acts as a gear with a screw-like structure, while the worm wheel has a tooth structure like a gear that meshes with the worm. This system converts rotational motion and offers a high torque ratio, making it suitable for various applications, such as conveyor systems, and electric motors, among others. Worm gearboxes are available in different sizes to suit various applications. The types of worm gearboxes are as discussed below.

Parallel Worm Gearbox

Hollow Worm Gearbox

Hollow Shaft Worm Gear

Worm Gearbox with Output Shaft

Each of these worm gearbox hollow shaft types has unique features and advantages, making them suitable for various applications. For instance, the parallel worm gearbox is known for its compact design and high efficiency, while the hollow shaft worm gear is ideal for applications requiring lightweight and high torque transmission.

Regular Lubrication

The worm shaft gearbox should be lubricated properly and regularly to avoid wear and tear. The lubricant decreases friction between the gearbox's moving components. It is important to use the right type and amount of lubricant as per the manufacturer's advice. Too much or too little lubricant can cause problems. The lubricant should also be checked regularly for quality. Contaminants or changes in texture can indicate issues within the gearbox that need attention. When adding or replacing lubricant, ensure it distributes evenly throughout all necessary areas of the gearbox for optimal protection.

Proper Alignment

Correct alignment of the worm shaft with other components like motors and machines is crucial. Misalignment can create excess strain on the gearbox parts over time, leading to premature failure. Visual inspection should be performed to ensure everything connects smoothly without abnormal angles or gaps. The components should be checked periodically for signs of misalignment, such as unusual vibrations or noises. Adjustments should be made if needed to keep everything in the intended position. Taking this preventive action will help maintain even, reliable operation from the gearbox and attached systems.

Tensioning Belts and Chains

If the worm shaft gearbox uses belts or chains, these should be properly tensioned according to specifications. Too much slack can cause slippage, while excessive tightness puts stress on the components. The correct tension promotes smooth power transfer without overworking the parts. Tensioning should be performed routinely, especially in high-load applications. Visuals should be checked for any deviations from the desired tightness.

Temperature Monitoring

The gearbox should be monitored to ensure it operates within the recommended temperature range. Overheating can damage internal components over time. Heat buildup may indicate issues like insufficient lubrication or excessive load that need to be addressed. For some applications, devices can be installed to continuously track the gearbox temperature. Alarms can warn of overheating, allowing timely intervention before severe harm occurs. Even in lower-risk situations, the temperature should be periodically felt manually. Abnormal high readings may signal problems requiring immediate action.

Regular Inspection

The worm gearbox should be visually checked regularly for signs of problems. Components like housing, seals, and bearings should be looked at closely for wear, cracks, or leaks. Any damage should be repaired quickly to avoid worsening. Fasteners like bolts and nuts holding the gearbox together should be inspected. Loose or missing ones can create issues over time if not addressed. Lubricant levels and condition should also be assessed during inspections.

Load Management

Guidelines for maximum loads that the gearbox can handle should be followed. Consistently overloading places excess strain on the components, leading to premature failure. The intended application should be considered before selecting a gearbox. A gearbox with a worm hollow shaft suitable for the required tasks should be gotten.

Environmental Considerations

The gearbox should be protected from extreme weather like high heat, moisture, or dust. Such conditions can affect its performance and longevity. If used in harsh areas, extra measures such as weatherproof housing or moisture barriers should be installed.

Electrical Maintenance

If the gearbox is linked to an electric motor, the electrical connections and components should be regularly checked. Loose wiring or damage can interrupt power transmission and impact gearbox operation.

Choosing the right worm gearboxes for a specific application requires careful consideration of several factors, including:

Load Capacity

Consider both the static and dynamic loads the gearbox can handle. Select a gearbox with a higher load capacity than the maximum load to avoid mechanical failure.

Gear Material and Construction

Different materials offer varying strengths, durability, and resistance to wear. Choose a worm gearbox hollow shaft with high material construction suitable for the application environment.

Gear Ratio

Select a gear ratio that suits the application requirements. A higher gear ratio offers more torque but reduces speed, while a lower ratio provides the opposite effect.

Mounting and Installation

Consider the gearbox's design, size, and weight to ensure it fits adequately in the available space. Additionally, choose a gearbox that is easy to install and maintain.

Environmental Conditions

Consider external factors such as temperature, humidity, and exposure to corrosive substances or dust. Choose a worm hollow shaft gear that withstands the prevailing environmental conditions in the application.

Service and Support

Consider the availability of service and support from the manufacturer or supplier. Choose a supplier known for timely and reliable service to ensure smooth operation and quick problem resolution.

Replacing a worm gearbox hollow shaft can be a complex task, but with the right tools and some mechanical knowledge, it can be done. Here’s how to do it:

Tools Needed:

Step-by-Step Guide:

Q1: How is a hollow shaft worm gearbox different from a regular worm gearbox?

A1: The only difference in the worm gearbox that is hollow is that its shaft is hollow. The design of the worm gearbox remains the same as the regular worm gearbox, which uses a worm and a worm wheel to achieve the desired gear ratio.

Q2: What is the benefit of using a hollow shaft in a worm gearbox?

A2: A hollow shaft can be beneficial in many ways. It helps reduce the overall weight of the gearbox without compromising its strength. A gearbox with a increased hollow shaft can be mounted directly onto bearings and other components, thus eliminating the need for extra supports and adapters. A hollow shaft can also allow for internal cable routing.

Q3: What materials are used to make the hollow shaft worm gearboxes?

A3: Multiple materials can be used to manufacture the hollow shaft worm gearboxes. The most common include stainless steel, steel alloy, brass, cast iron, and aluminum. Each material has its own advantages and is suitable for various applications. For example, stainless steel and aluminum are suitable for applications where corrosion resistance is required.

Q4: Can users customize the hollow shaft worm gearboxes?

A4: Yes, it is possible to customize the hollow shaft worm gearboxes. Users can specify the gear ratio they require, the size of the shafts and other features such as mounting options, lubrication type and material. Customization can help the gearbox meet specific application requirements.

The web search volume for the keyword "worm gearbox hollow shaft" has shown a significant upward trend over the past year, with an average monthly web search volume of 10. Notably, there has been a 200% increase in both the three-month and one-year periods, reflecting growing interest in this specific industrial machinery component.

Analyzing the monthly search data over the last twelve months, we observe fluctuations that suggest a pattern of varying interest. Starting from December 2023 with 10 web searches, there was a notable spike in January 2024, reaching up to 50 web searches, before settling back to lower levels of 20 web searches in February and March, and then stabilizing at 10 web searches from April to September, except for a rise again in November to 30 web searches. These peaks and valleys in web search volume indicate periods of heightened demand or interest, possibly aligned with specific industry needs or seasonal projects.

The reasons behind these trends could be manifold, ranging from market demands driven by new industrial projects or upgrades, to seasonal influences affecting the construction or manufacturing sectors which heavily rely on such machinery. While the provided data does not delve into the specifics of why these trends occur, it is clear that the web search volume for "worm gearbox hollow shaft" is subject to significant variability, potentially mirroring broader economic or industry-specific factors.